112s in a 120fb chamber are going below neck shoulder by the time you get maybe 25-30k off lands. I much prefer the 169fb chambers.2850fps from 32gr is pretty sweet.

Is the bearing surface of your 108/109s below the shoulder/neck junction running a 60-65 thou jump?

I’m wondering if my bullets are just long (112 Match Burners) or is my chamber short too (SAAMI/Proof prefit)? Because 60-65 thou off would probably put the base of my bullets below the start/bottom of the shoulder (though I’m not necessarily convinced that matters lol).

Ideally more jump usually work better for me in 6CM, so I’d like to jump as much as 100 thou if I could, but that’d put a whole bunch of bullet deep into the case (which again, might not matter).

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6gt

- Thread starter Dthomas3523

- Start date

If your smith is local he can add free bore to your barrel and shouldn't need to put it into the lathe or even remove the barrel from the action...this is something you can do yourself as well...if you trust yourself to do it.

Premium Uni-Throater Kit - Pacific Tool and Gauge

Premium Uni-Throater Kit at Pacific Tool and Gaugepacifictoolandgauge.com

This isn’t a bad idea, though I’ve always felt it’s best to stay fairly vanilla as far as chambers go so one can piggyback off others’ data/experience… but it seems like the 6GT SAAMI chamber’s freebore is kinda short.

I might end up with that reamer though… I’ll try seating the bullets deeper first, but that might be where I end up.

I’m wondering what bullet George and Tom designed the GT around (thinking 105 hybrids)?

IME I’ve found that is you have sufficient neck clearance, like 5-6K, you can run the bearing surface below the neck/shoulder junction without a problem. If you only have 2-3K I find I start to get doughnuts at the neck/shoulder junction after a few firings.

Any idea how I can figure how much clearance I’ve got besides trial and error lol..?

(SAAMI looks like .274 and without measuring/off the top off my head I think my loaded rounds/necks are ~.272 or so… I can measure them later.)

This isn’t a bad idea, though I’ve always felt it’s best to stay fairly vanilla as far as chambers go so one can piggyback off others’ data/experience… but it seems like the 6GT SAAMI chamber’s freebore is kinda short.

I might end up with that reamer though… I’ll try seating the bullets deeper first, but that might be where I end up.

I’m wondering what bullet George and Tom designed the GT around (thinking 105 hybrids)?

Most all SAAMI free bore's are short...I shot a 6BRA for a few years and after a bunch of adjusting free bore I had a reamer made with a .275 neck and .145 free bore....4 barrels and every one shot at 50 to 70 off both 105s and 109s...also shot several different calibers and I always had the best luck with big jumps.

I don't know the answer, but Tom's bullet is 103 grains.This isn’t a bad idea, though I’ve always felt it’s best to stay fairly vanilla as far as chambers go so one can piggyback off others’ data/experience… but it seems like the 6GT SAAMI chamber’s freebore is kinda short.

I might end up with that reamer though… I’ll try seating the bullets deeper first, but that might be where I end up.

I’m wondering what bullet George and Tom designed the GT around (thinking 105 hybrids)?

I was looking here: https://www.jbmballistics.com/ballistics/lengths/lengths.shtml

…and looks like the bullet I’m using, 112MB, is 1.331” in length, as compared to a 105MB at 1.199” Hornady 105BTHP at 1.220”, 110 A-Tip at 1.307”, and a 105 hybrid at 1.282”…

So looks like the bullets I’m using are kind of long, and depending on ogive, the SAAMI freebore might play nicer with the shorter 105s, a Hornady 105BTHP would give me another 111 thou to play with, even a 110 A-Tip would give me another 24 thou (again, depending on ogive)…

…and looks like the bullet I’m using, 112MB, is 1.331” in length, as compared to a 105MB at 1.199” Hornady 105BTHP at 1.220”, 110 A-Tip at 1.307”, and a 105 hybrid at 1.282”…

So looks like the bullets I’m using are kind of long, and depending on ogive, the SAAMI freebore might play nicer with the shorter 105s, a Hornady 105BTHP would give me another 111 thou to play with, even a 110 A-Tip would give me another 24 thou (again, depending on ogive)…

Measure the necks of loaded and fired cases and subtract the loaded from fired. If you have a powerful ejector spring make sure the neck isn’t dents from that or hitting the ground. Measure a few just to me sure.Any idea how I can figure how much clearance I’ve got besides trial and error lol..?

(SAAMI looks like .274 and without measuring/off the top off my head I think my loaded rounds/necks are ~.272 or so… I can measure them later.)

Alpha reamers are 274 neck. New loaded neck diameter is 269. After 6 firings it's 270 on the lower half my necks now due to some brass flow. Still no issues. 22gt is the problem child on neck clearance. Alpha finally went to a bigger necked reamer a month ago, I told them there was a problem in January of last year.Any idea how I can figure how much clearance I’ve got besides trial and error lol..?

(SAAMI looks like .274 and without measuring/off the top off my head I think my loaded rounds/necks are ~.272 or so… I can measure them later.)

No, just referring to my applications of patchout and accelerator between brushing.Bore treatments, are you using HBN?

Not in this .0170 alpha chamber, I forget how the Alpha .120 chambers lined up but if it was, it didn't cause problems.Is the bearing surface of your 108/109s below the shoulder/neck junction running a 60-65 thou jump?

I forget how the Alpha .120 chambers lined up but if it was, it didn't cause problems.

I didn't notice that I had my bearing surface below the shoulder/neck junction for like 900, maybe 1200 rounds lol. I loaded the first 300 to whatever the average SAAMI COAL is on virgin brass and shot them (low charge, baseline MV, stabilize barrel speed). Cleaned it, measured the distance to the lands, learned they were .050" off, they shot great so I just left it there... didn't even consider the bearing surface, base of the bullet, blah blah blah.

Then one day I was reading something about reloading somewhere and it was mentioned (along with donuts forming) and I was like "oh shit, oh yeah, that" lol.

Still not sure it matters. I've got 150 loaded now that are 10 off that I may just seat deeper to see what I get.

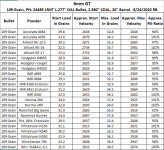

no, i called and got thisDoes the Berger book have any factory data for the 109s in 6GT?

Attachments

Not on their list, but N555 was the first powder I tried.Does the Berger book have any factory data for the 109s in 6GT?

38.6 = 2920 with 109 LRHT @ 2.588". Shot so well I've never tried another powder.

Does the Berger book have any factory data for the 109s in 6GT?

That only matters when they start producing 109s again.no, i called and got this

They just ran 105s, 109s be hitting now.That only matters when they start producing 109s again.

33.6 of Varget pushing a 105 Hybrid 2850ish. I was jumping them .040 or so when I started 2100 rounds ago and haven't looked back.curious if anyone is running varget with 105's. what your load and speed are?

im currently running 34gr under a 108bt for 2880 from a 24", but may try some 105's

Still hammers.

Anyone have the Berger Load sheet for 6GT with the 108's before I call them tomorrow afternoon?

Load it with 31.5 to 33.5 gr of Varget and it will shoot bugholes.Anyone have the Berger Load sheet for 6GT with the 108's before I call them tomorrow afternoon?

berger said it uses the same data as the 109s i post up the pageAnyone have the Berger Load sheet for 6GT with the 108's before I call them tomorrow afternoon?

but i am using 34gr of varget

So for Varget there is a three grain variance from short load to max. And max velocity is 2857.

I wonder what powder Hornady is putting in their Match cartridges that is driving the 109 Hornady bullet to 2950 or so.

I wonder what powder Hornady is putting in their Match cartridges that is driving the 109 Hornady bullet to 2950 or so.

this is what i got from a 24" barrelSo for Varget there is a three grain variance from short load to max. And max velocity is 2857.

I wonder what powder Hornady is putting in their Match cartridges that is driving the 109 Hornady bullet to 2950 or so.

108bt and varget

Wow, that is very different from what is published. And your bullet is only one grain different.this is what i got from a 24" barrel

108bt and varget View attachment 8285602

but its more inline with what hodgdon hasWow, that is very different from what is published. And your bullet is only one grain different.

Need's ya'll .02 on this matter.

I just got my MPA Matrix Pro 6GT on Friday did some loading at found out it liked this load of Varget with 109's the best. I'm not an expert shot by any means the one small group was a shear fluke lol I average the other two maybe a little smaller with my other rifles. My Velocity was from inconsistent across a few strings and my SD's were like 15 for each string. But these are my groups I shot 5 at 200yards (Max range) and they all stacked into a nice SUB-MOA group without any issues. I'm not a pro PRS Guy just regional matches. I'm thinking it might be the primers maybe? I was going to load same load with my CCI BR-4 and Federal AR Match that I have to see if that helps. My Labrador though was kicking mud butt still working on getting used to using it would not pickup a lot of the shots was only getting like data on 2 or 3 of the 5 if that so I think it was moving because of my muzzle brake or rocking on the bench. All shots were at 100yards with bipod and rear bag today its 54f little wind, but misty.

I measure the OAL of the bullets today they are from 1.270 to 1.289 big difference from Bergers

Load:

Varget 34.0 (Auto Trickler v4)

Berger 109 (Meplat Trimmed)

COAL: 2.605

Lands: 2.620

Jump: .15

Alpha OCD Virgin Brass ( resized it before loading)

Remt 7 1/2 BR Primer

Lab Radar

I just got my MPA Matrix Pro 6GT on Friday did some loading at found out it liked this load of Varget with 109's the best. I'm not an expert shot by any means the one small group was a shear fluke lol I average the other two maybe a little smaller with my other rifles. My Velocity was from inconsistent across a few strings and my SD's were like 15 for each string. But these are my groups I shot 5 at 200yards (Max range) and they all stacked into a nice SUB-MOA group without any issues. I'm not a pro PRS Guy just regional matches. I'm thinking it might be the primers maybe? I was going to load same load with my CCI BR-4 and Federal AR Match that I have to see if that helps. My Labrador though was kicking mud butt still working on getting used to using it would not pickup a lot of the shots was only getting like data on 2 or 3 of the 5 if that so I think it was moving because of my muzzle brake or rocking on the bench. All shots were at 100yards with bipod and rear bag today its 54f little wind, but misty.

I measure the OAL of the bullets today they are from 1.270 to 1.289 big difference from Bergers

Load:

Varget 34.0 (Auto Trickler v4)

Berger 109 (Meplat Trimmed)

COAL: 2.605

Lands: 2.620

Jump: .15

Alpha OCD Virgin Brass ( resized it before loading)

Remt 7 1/2 BR Primer

Lab Radar

Attachments

Last edited:

The only difference I ever notice with primers is, assuming one seats them fully and hasn't bumped their shoulders too much, some go "bang" more than others... I get the same accuracy/performance whether I use CCI450s or Winchester #41s (FWIW I have found the Win41s to be more problematic and less reliable in my gun).

Using Varget and Bergers, I'd be concerned with an SD that wasn't in the single digits or in the low teens over those few shots (even on virgin brass), and I'd bet it's not your primers. (Maybe not enough brass prep, or maybe too much brass prep?)

IMHO, even though that's probably not hot enough to show any signs with Alpha brass, 34gn of Varget behind a 109 at less than 20 thou off sounds like you're running on the edge of pressure (especially this time of year), and things get spikey up there. If it were me, I'd back it off a grain, and see if it settles down a little SD-wise, groups might get more consistent too.

YMMV.

Using Varget and Bergers, I'd be concerned with an SD that wasn't in the single digits or in the low teens over those few shots (even on virgin brass), and I'd bet it's not your primers. (Maybe not enough brass prep, or maybe too much brass prep?)

IMHO, even though that's probably not hot enough to show any signs with Alpha brass, 34gn of Varget behind a 109 at less than 20 thou off sounds like you're running on the edge of pressure (especially this time of year), and things get spikey up there. If it were me, I'd back it off a grain, and see if it settles down a little SD-wise, groups might get more consistent too.

YMMV.

Last edited:

Need's ya'll .02 on this matter.

I just got my MPA Matrix Pro 6GT on Friday did some loading at found out it liked this load of Varget with 109's the best. I'm not an expert shot by any means the one small group was a shear fluke lol I average the other two maybe a little smaller with my other rifles. My Velocity was from inconsistent across a few strings and my SD's were like 15 for each string. But these are my groups I shot 5 at 200yards (Max range) and they all stacked into a nice SUB-MOA group without any issues. I'm not a pro PRS Guy just regional matches. I'm thinking it might be the primers maybe? I was going to load same load with my CCI BR-4 and Federal AR Match that I have to see if that helps. My Labrador though was kicking mud butt still working on getting used to using it would not pickup a lot of the shots was only getting like data on 2 or 3 of the 5 if that so I think it was moving because of my muzzle brake or rocking on the bench. All shots were at 100yards with bipod and rear bag today its 54f little wind, but misty.

I measure the OAL of the bullets today they are from 1.270 to 1.289 big difference from Bergers

Load:

Varget 34.0 (Auto Trickler v4)

Berger 109 (Meplat Trimmed)

COAL: 2.605

Lands: 2.620

Jump: .15

Alpha OCD Virgin Brass ( resized it before loading)

Remt 7 1/2 BR Primer

Lab Radar

View attachment 8287479

Load 33.0gr of Varget, and seat the 109's around .030 jump. Haven't found a chamber yet in either our, or our customer's rifle's that it doesn't work at least pretty well in. Always with cci450. Usually runs about 2850 in a 26" barrel once the barrel speeds up.

I'm sure there's plenty other recipes, but this is just easy button. Its like the tried and true 6br 30gr varget and Berger 105's.

Also, the Berger 109 is one of, if not the most consistent mass produced bullet available. I'd be surprised if you actually improve anything meplat trimming.

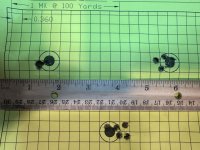

The pic below with three pics is chrono for the first 10 shots out of a freshly chambered barrel and the group is shots 6-10 (first 5 shots were just function test). Barrel is still settling in.

The other pic is 5 build and break shots (5 different positions on barricade) with same load in a proof prefit barrel for Falkor 7even. This was after barrel had about 30rnds. 100yds. Rifle and bag only.

Long story short.....don't complicate 6gt. Neither of these is cherry picked. This .562 group is one of the larger we've seen with this ammo.

Last edited:

Here's a third 6gt from today. It was chambered by another smith a couple years ago for a defiance. Barrel has about 2k rnds.

Today alone was three different rifles, chambered three different places. Same ammo.

The single shot upper right was from the bore sight. Adjusted and shot four more rounds to zero.

Today alone was three different rifles, chambered three different places. Same ammo.

The single shot upper right was from the bore sight. Adjusted and shot four more rounds to zero.

Correction I meant 33grns of Powder not 34 I went .2 over book max from the previous post with the load data.

Sorry, but I seem to have missed what kind of barrel you are using here? Thanks!I'm at 1850rds through my first 6GT barrel and it's still shooting great. I've already got another barrel, but I'm going to try and hold off on pulling my first one as long as I can as I'm curious how long it'll make it?

Wait, what!?! Hadn’t heard of this happening before with that particular factory ammo. What is your barrel and action setup please?The only rounds I have shot in this rifle are the Hornady Match factory ammo (which I stopped using after pierced primers broke my trigger

Wait, what!?! Hadn’t heard of this happening before with that particular factory ammo. What is your barrel and action setup please?

It's not unheard of. I've had blown primers in a saami 6cm chamber with 108eldm factory ammo.

Sorry, but I seem to have missed what kind of barrel you are using here? Thanks!

Proof SS prefit (comp contour), I’m at 2100rds on it and it’s still shooting…

That’s a real bummer to hear, especially for the off-the-shelf guys like me!It's not unheard of. I've had blown primers in a saami 6cm chamber with 108eldm factory ammo.

Bartlein barrel, impact 737R action - it has happened to lots and lots of shooters with that ammunition.Wait, what!?! Hadn’t heard of this happening before with that particular factory ammo. What is your barrel and action setup please?

It does not happen with 205M or CCI 450 primers, but Hornady does not use those primers.

Impact now makes a small firing pin bolt ($465), and I have seen two reports that it fixed the issue for those two.

Got it...I guess I will be rolling the dice as I am currently an "off the shelf" ammo buyer.Bartlein barrel, impact 737R action - it has happened to lots and lots of shooters with that ammunition.

It does not happen with 205M or CCI 450 primers, but Hornady does not use those primers.

Impact now makes a small firing pin bolt ($465), and I have seen two reports that it fixed the issue for those two.

I've have had such a great experience with 6.5CM match ammo; my current rifle loves it all, and according to my Labradar thingy it especially loves the Hornady 140gr ELDM factory. But the 6.5CM was going to move to practice rifle and I wanted to add a 6GT for competition (I'll still suck, but maybe i can sit with the cool kids

Being a factory ammo buyer, I started to regularly see, and accumulate, the 6GT factory loads (some day I'll dive down the reloading hole after I've paid off all this other crap) Anyhow, my 737R--with the small firing pin bolt (I got lucky on that last part, thanks @Bugholes!!) is already bought and in the mail, so we'll cross fingers. Thanks again for the details.

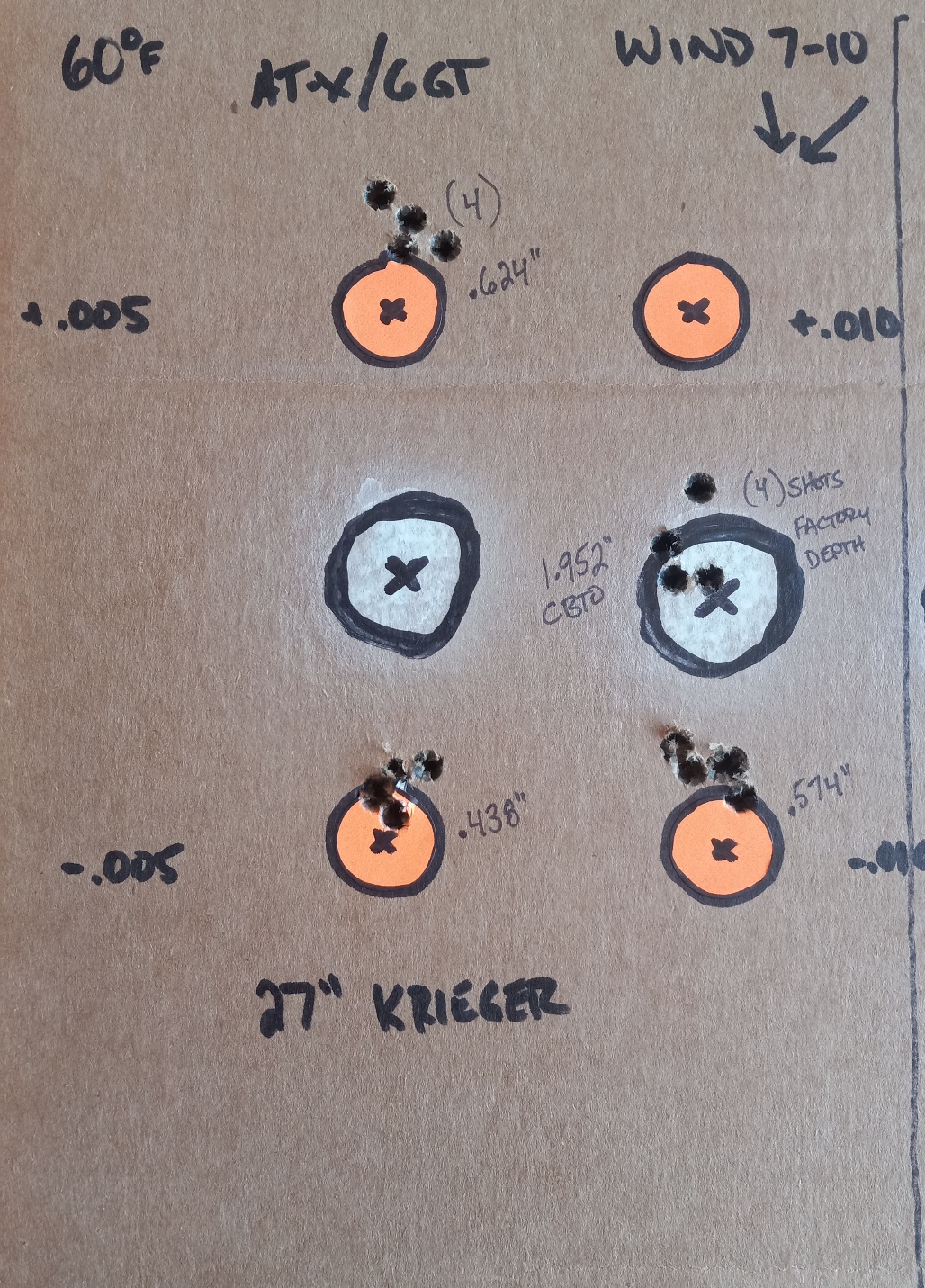

Just jumping in as I've got a 6gt barrel spun up for my AT-X. I just started breaking it in, and am at 38 rounds down the tube so far. I'm using Eagle Eye ammo with the 105 Hybrid for this process, and then will reload the Alpha brass when I'm done with this box. I'm guilty of using factory ammo to get the first 50 - 100 rounds on a barrel.

So far, I started by shooting 5 groups of either 4-5 rounds between cleaning. Every one had a single flier that opened the group up to around 3/4 MOA. Once or twice, it's probably me sucking, but I got suspicious when it was all 5 groups. I seated another group of 5 down .005 from factory and that next group was in the .4s with no more fliers. I seated another .005 down (.010 total) and it was just over a half minute- again with no fliers. So I went ahead and seated the remaining rounds .005 down from what they came at (I'm now at 1.947 CBTO).

I did try one group at .005 above factory, but it was a consistent pattern that was opening up, so I figure the -.005 is the sweet-enough spot. I disassembled one round and got 33.5gr of a powder that looks a lot like either N150 or Reloader 16. I was thinking I'd see Varget or H4350, but it was definitely not.

I'll get some velocities as I get closer to finishing this stuff. Unfortunately, all I have to start with is 107 SMKs or 108 ELD-Ms.

Right now:

105 hybrid

33.5gr unknown powder

Unknown SRP

Alpha OCD brass

1.947 (new) CBTO.

Rifle is an AT-X with 27" Krieger M24, 1:8, with .237/.243.

And so begins my 6gt journey.

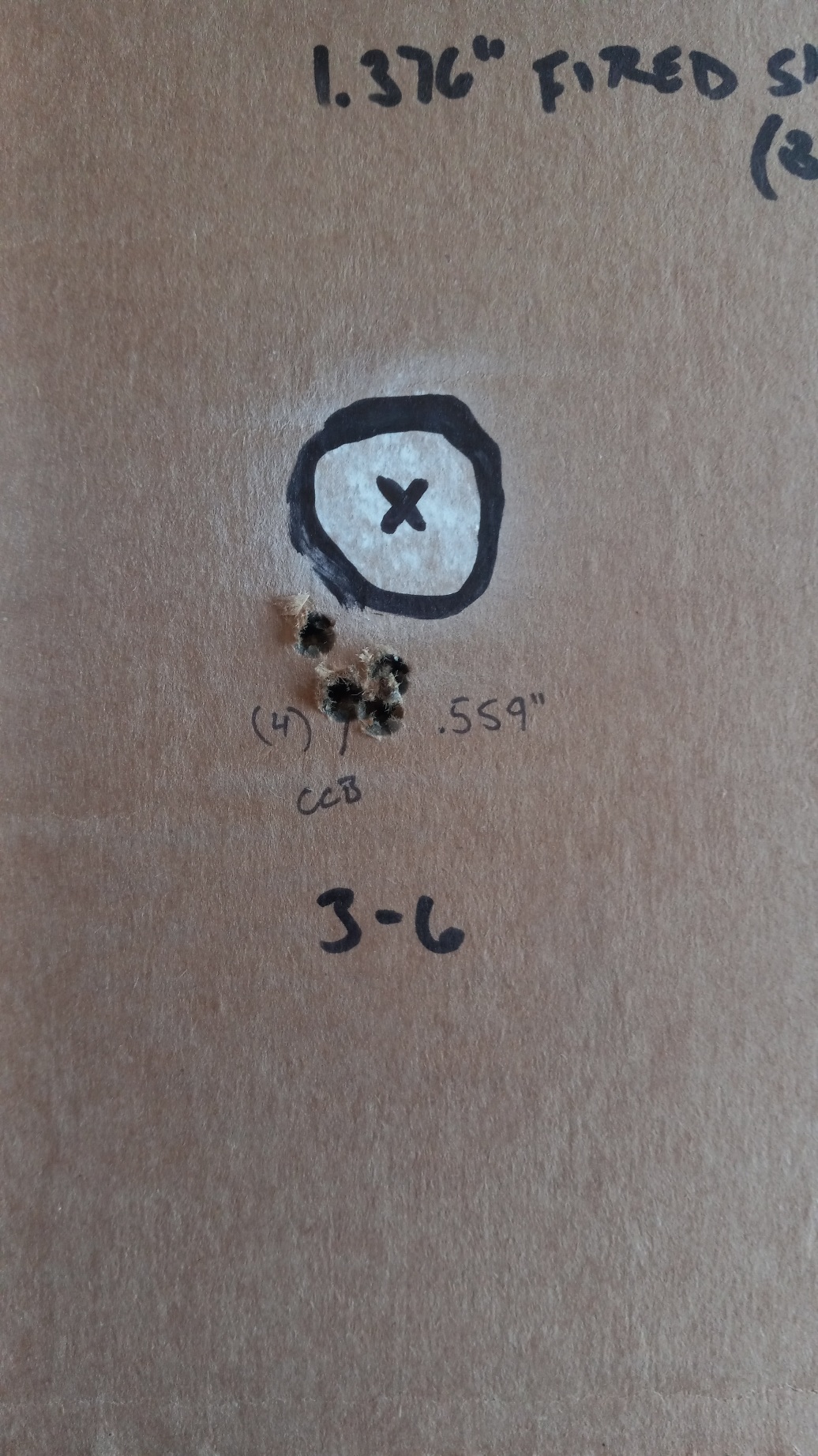

Shots 3, 4, 5, and 6 on the barrel.

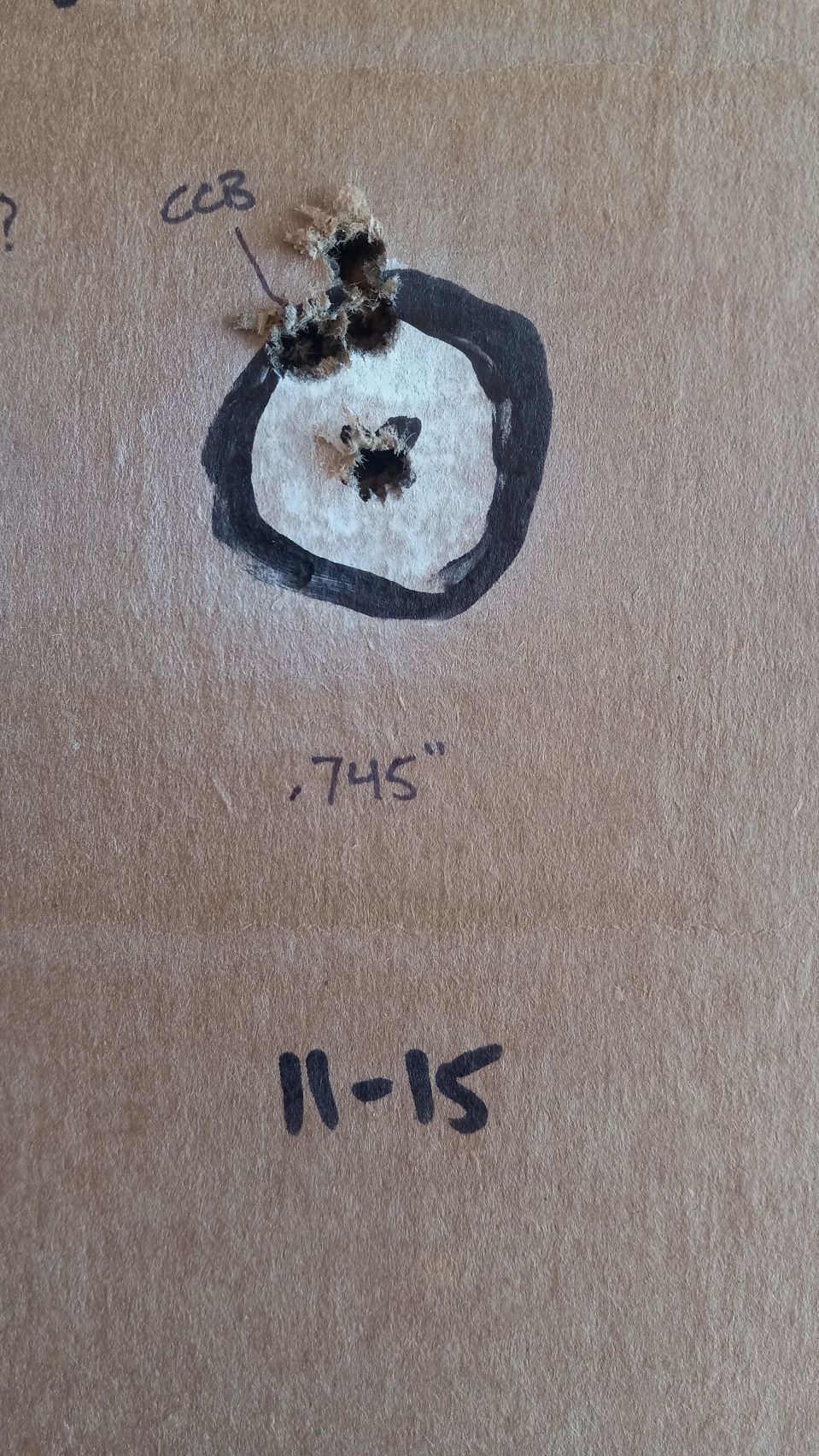

Shots 11 - 15, my first 5 shot group during break-in in. The single uncalled flier became a trend until I played just a smidgen with the seating depth.

So far, I started by shooting 5 groups of either 4-5 rounds between cleaning. Every one had a single flier that opened the group up to around 3/4 MOA. Once or twice, it's probably me sucking, but I got suspicious when it was all 5 groups. I seated another group of 5 down .005 from factory and that next group was in the .4s with no more fliers. I seated another .005 down (.010 total) and it was just over a half minute- again with no fliers. So I went ahead and seated the remaining rounds .005 down from what they came at (I'm now at 1.947 CBTO).

I did try one group at .005 above factory, but it was a consistent pattern that was opening up, so I figure the -.005 is the sweet-enough spot. I disassembled one round and got 33.5gr of a powder that looks a lot like either N150 or Reloader 16. I was thinking I'd see Varget or H4350, but it was definitely not.

I'll get some velocities as I get closer to finishing this stuff. Unfortunately, all I have to start with is 107 SMKs or 108 ELD-Ms.

Right now:

105 hybrid

33.5gr unknown powder

Unknown SRP

Alpha OCD brass

1.947 (new) CBTO.

Rifle is an AT-X with 27" Krieger M24, 1:8, with .237/.243.

And so begins my 6gt journey.

Shots 3, 4, 5, and 6 on the barrel.

Shots 11 - 15, my first 5 shot group during break-in in. The single uncalled flier became a trend until I played just a smidgen with the seating depth.

Any particular reason you went with a 1:8? I’m a noob on this, and haven’t picked out my 6gt barrel yet but I was reading that 6gt leaned towards a faster rate…?Just jumping in as I've got a 6gt barrel spun up for my AT-X. I just started breaking it in, and am at 38 rounds down the tube so far. I'm using Eagle Eye ammo with the 105 Hybrid for this process, and then will reload the Alpha brass when I'm done with this box. I'm guilty of using factory ammo to get the first 50 - 100 rounds on a barrel.

So far, I started by shooting 5 groups of either 4-5 rounds between cleaning. Every one had a single flier that opened the group up to around 3/4 MOA. Once or twice, it's probably me sucking, but I got suspicious when it was all 5 groups. I seated another group of 5 down .005 from factory and that next group was in the .4s with no more fliers. I seated another .005 down (.010 total) and it was just over a half minute- again with no fliers. So I went ahead and seated the remaining rounds .005 down from what they came at (I'm now at 1.947 CBTO).

I did try one group at .005 above factory, but it was a consistent pattern that was opening up, so I figure the -.005 is the sweet-enough spot. I disassembled one round and got 33.5gr of a powder that looks a lot like either N150 or Reloader 16. I was thinking I'd see Varget or H4350, but it was definitely not.

I'll get some velocities as I get closer to finishing this stuff. Unfortunately, all I have to start with is 107 SMKs or 108 ELD-Ms.

Right now:

105 hybrid

33.5gr unknown powder

Unknown SRP

Alpha OCD brass

1.947 (new) CBTO.

Rifle is an AT-X with 27" Krieger M24, 1:8, with .237/.243.

And so begins my 6gt journey.

View attachment 8296762

Shots 3, 4, 5, and 6 on the barrel.

View attachment 8296765

Shots 11 - 15, my first 5 shot group during break-in in. The single uncalled flier became a trend until I played just a smidgen with the seating depth.

View attachment 8296769

Any particular reason you went with a 1:8? I’m a noob on this, and haven’t picked out my 6gt barrel yet but I was reading that 6gt leaned towards a faster rate…?

Yes, good question. I plan on shooting bullets no heavier (longer) than 108gr. I have a 1:7.25", 26" 6 Creed barrel for the same rifle and didn't want a complete overlap with 110gr +.

I've done the same in my own little 6.5mm realm because I have two 6.5x47s and two 6.5 Creedmoors. My x47s were chambered with a .123 freebore as I just shoot 123 - 130gr bullets out of them. That leaves the 140s for the Creeds.

I don't compete. I'm just a good old boy who likes to shoot out of his shop and wander down onto the pastures to bang on some steel...and then I come on here and ramble excessively.

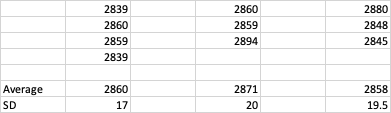

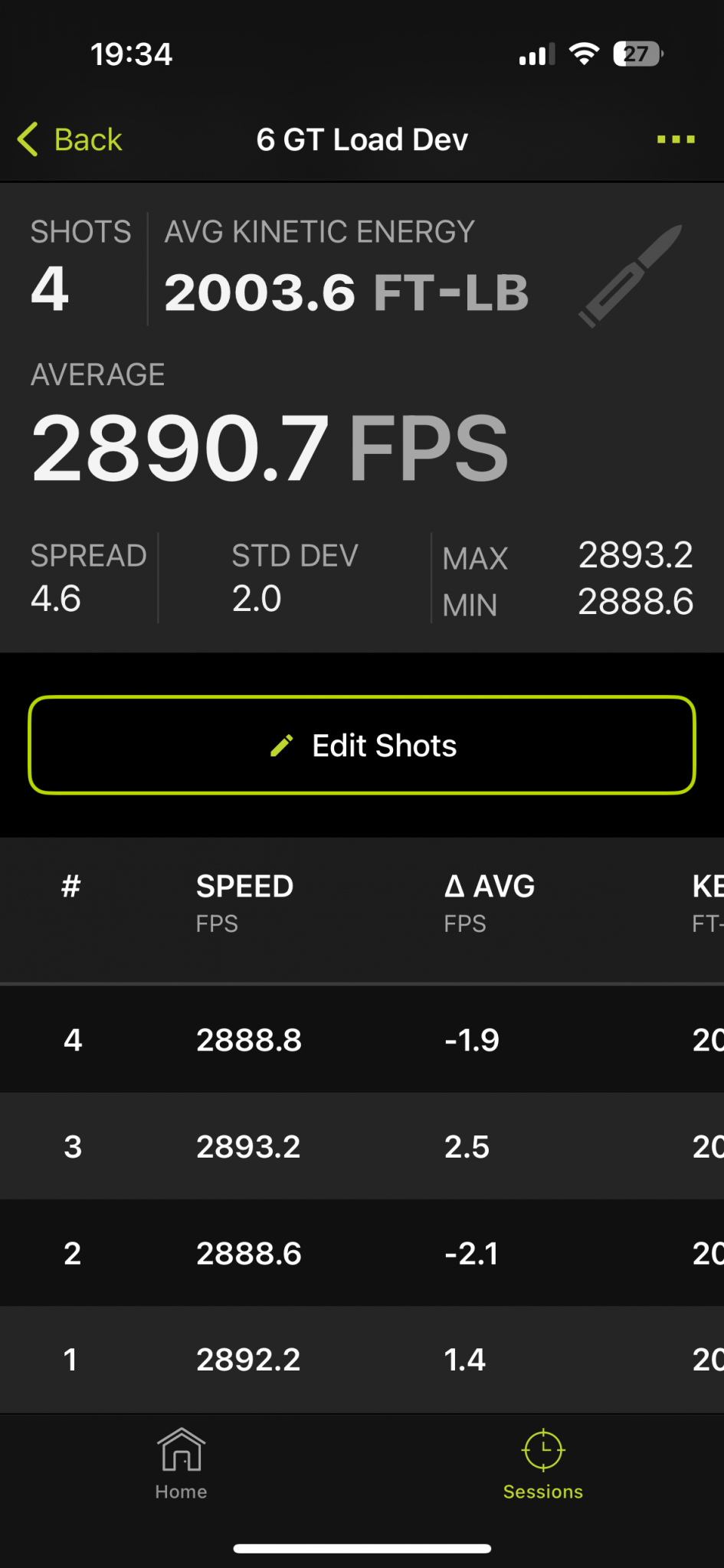

Got my garmin in hand this and took it out last weekend to finish my 6GT load dev. 36Gr of H4350, with a 108Eld seated to 1.994 CBTO

Got my garmin in hand this and took it out last weekend to finish my 6GT load dev. 36Gr of H4350, with a 108Eld seated to 1.994 CBTO

View attachment 8300517

Thanks for sharing. These are the same components that I will be starting with. Alpha or Hornady brass, and what length barrel? (sorry if I missed it earlier).

Alpha OCD Brass, FGMM SRP and 26” barrelThanks for sharing. These are the same components that I will be starting with. Alpha or Hornady brass, and what length barrel? (sorry if I missed it earlier).

Those of you shooting the 112 MB - what b.c. value have you trued to? I'm just now getting into truing the b.c. for this bullet in my 1:7 twist and it's looking like .300-.310 (G7); need to test further to confirm though.

My son and I put together a 6GT over the past few months just as a fun gun for plinking steel at distance in the mountains, and I wanted to use the heavies so we picked up a selection of 105-115gr bullets from what was easily available. With a little experimenting I've settled on the 112 MB for now.

I was trying to find the post with the load I settled on but it must be way back in this thread - someone said they'd settled on 36.5gr H4350 with the 112 MB jumping .020". I worked up to this and did load dev for seating depth, powder charge, and primers - ended up back at almost exactly the same load, just 36.3gr seems to be right in the middle of the sweet spot with this barrel, doing 2920 fps. (26" 1:7 Schnieder, heavy MTU profile).

It does seem like an easy one to load for - even the worst groups I found were in the .7-.8 moa range for 5 rounds, with the above load pretty consistently in the .38-.42 moa range across multiple shooting trips and load development rounds in various temps. Most likely it'd shoot better than that in better hands too, that's about my lower limit for consistent accuracy off a bipod and shooting bag.

I've been comparing the 112 MB to the 115 RDF as well, but just don't like that RDF as much. Even the best loads are giving me more vertical dispersion, b.c. seems slightly lower, and it seats quite a bit farther into the case for the same .020" jump; no advantage I can see, although they shoot well enough for banging steel and letting the kid practice I guess, if it comes down to that. I haven't been real excited about the 106 Amax in this one either; accuracy just wasn't as good even with some sorting - still well under 1 moa but not what I'd look for in a precision long range gun. Haven't tried the 110 Amax yet though, and of course all those 106 Amax bullets from PV were seconds, so no big surprise there.

My son and I put together a 6GT over the past few months just as a fun gun for plinking steel at distance in the mountains, and I wanted to use the heavies so we picked up a selection of 105-115gr bullets from what was easily available. With a little experimenting I've settled on the 112 MB for now.

I was trying to find the post with the load I settled on but it must be way back in this thread - someone said they'd settled on 36.5gr H4350 with the 112 MB jumping .020". I worked up to this and did load dev for seating depth, powder charge, and primers - ended up back at almost exactly the same load, just 36.3gr seems to be right in the middle of the sweet spot with this barrel, doing 2920 fps. (26" 1:7 Schnieder, heavy MTU profile).

It does seem like an easy one to load for - even the worst groups I found were in the .7-.8 moa range for 5 rounds, with the above load pretty consistently in the .38-.42 moa range across multiple shooting trips and load development rounds in various temps. Most likely it'd shoot better than that in better hands too, that's about my lower limit for consistent accuracy off a bipod and shooting bag.

I've been comparing the 112 MB to the 115 RDF as well, but just don't like that RDF as much. Even the best loads are giving me more vertical dispersion, b.c. seems slightly lower, and it seats quite a bit farther into the case for the same .020" jump; no advantage I can see, although they shoot well enough for banging steel and letting the kid practice I guess, if it comes down to that. I haven't been real excited about the 106 Amax in this one either; accuracy just wasn't as good even with some sorting - still well under 1 moa but not what I'd look for in a precision long range gun. Haven't tried the 110 Amax yet though, and of course all those 106 Amax bullets from PV were seconds, so no big surprise there.

@Yondering I'm running the 112s 10k jump in my rifle, 309g7 was money to 880y perfect waterline at 2910-2920fps with 36.3gr H4350 from a 24" barrel. They shot equally as well at 100y at 36.6gr running 2950, but accuracy wasn't nearly as consistent on my targets at 660y and 880y.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 19

- Views

- 1K