I have 7 AAC cans. I frequently tout the mounts cause no accuracy issues, with or without can. But I have had two guns that the mount has destroyed accuracy. I need one more day on the range to prove it.

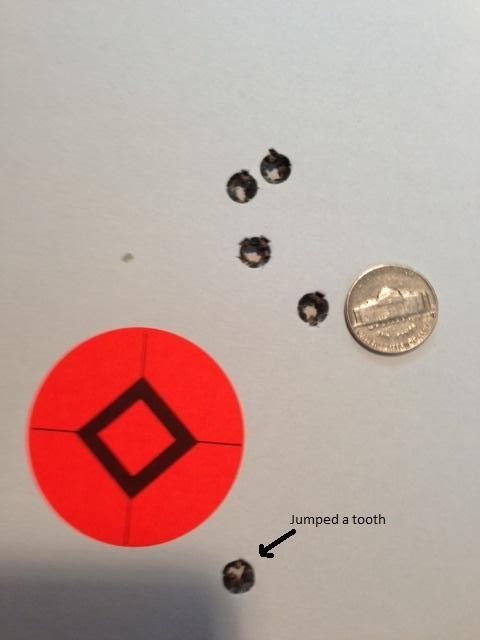

Here is the situation. I have 18 SPR with White Oak barrel that shot under a half inch all day long, SSA TRIGGER.... With 69g SMK or 77gr and would shoot VMAX great. It was my go to gun. It had a battle COMP on it. I put a AAC mount and it went to a 3 inch gun with sometimes worse. Crazy 6 inch groups. So I cleaned it and shot and shot , tried multiple loads. Kept on on for months, just thought I'm screwing up and kept making excuses.

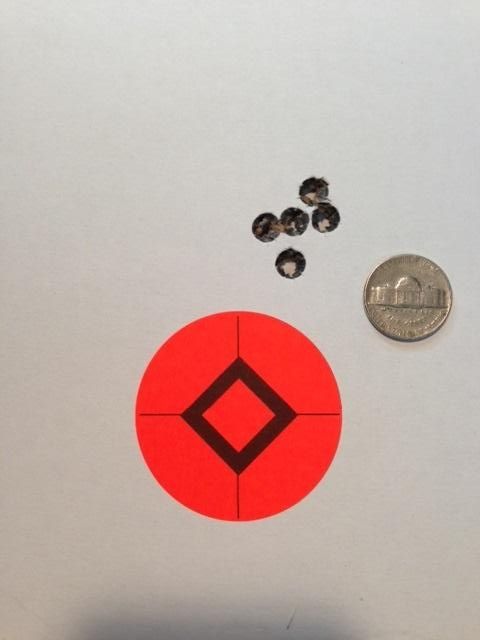

I removed mount, threw a birdcage on it and now I'm back under an inch. This is my second such experience .

Anyone else ?

PB

Here is the situation. I have 18 SPR with White Oak barrel that shot under a half inch all day long, SSA TRIGGER.... With 69g SMK or 77gr and would shoot VMAX great. It was my go to gun. It had a battle COMP on it. I put a AAC mount and it went to a 3 inch gun with sometimes worse. Crazy 6 inch groups. So I cleaned it and shot and shot , tried multiple loads. Kept on on for months, just thought I'm screwing up and kept making excuses.

I removed mount, threw a birdcage on it and now I'm back under an inch. This is my second such experience .

Anyone else ?

PB