What kind of rods? Is there much info on the net for that?If I were only going to be doing reloading in my space I might would do the same thing, but I need all my bench top at the same height for building fishing rods.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building the Perfect Reloading Room

- Thread starter sirhrmechanic

- Start date

Bass rods. Good ol’ college of YouTube will get you started, but I’m lucky enough to know a professional builder that helped me get things going. Not a business venture for me, but I like that I can take $75 to $100 worth of small parts, a high quality blank ($75-$150 on sale) and build something that is far better than the ones going $500-$600 at Bass Pro. As much as my family fishes, it’d take a second mortgage to outfit everyone with top quality rods otherwise.What kind of rods? Is there much info on the net for that?

Where are you getting that length?

Awesome!! I already scouted out YouTube. Will be jumping into that in a few weeks.Bass rods. Good ol’ college of YouTube will get you started, but I’m lucky enough to know a professional builder that helped me get things going. Not a business venture for me, but I like that I can take $75 to $100 worth of small parts, a high quality blank ($75-$150 on sale) and build something that is far better than the ones going $500-$600 at Bass Pro. As much as my family fishes, it’d take a second mortgage to outfit everyone with top quality rods otherwise.

Much thanks!!! I am excited about a new project!

Idk I’ll have to ask my builder, his carpenter did itWhere are you getting that length?

Just remember, it’s girth that’s most important.Where are you getting that length?

Man, what are you doing to break rods? I think in my entire life I have only broken 1 that I remember.For Christ's sake don't let you wife get hold of a tap measure.

Those special bass sticks, cool but they all get broken eventually.

Probably spend time on tuning reels, custom baits and reading the water.

Problem I have seen is that far too many of those rods (including fly rods) are made in good ole Red China. I hates Red China.Bass rods. Good ol’ college of YouTube will get you started, but I’m lucky enough to know a professional builder that helped me get things going. Not a business venture for me, but I like that I can take $75 to $100 worth of small parts, a high quality blank ($75-$150 on sale) and build something that is far better than the ones going $500-$600 at Bass Pro. As much as my family fishes, it’d take a second mortgage to outfit everyone with top quality rods otherwise.

Good luck on all your builds. I built several in the late 1970’s and early 1980’s. They did exactly what I wanted and needed and NO where could what i really needed be found in stores or tackle shops.

Not hard to find USA fly blanks - McFarland, Steffen, Livingston, T&T... Plus almost all of the higher-end "mainstream" fly rod manufacturers have blanks & rods that are USA, even if their entry level are ChineseProblem I have seen is that far too many of those rods (including fly rods) are made in good ole Red China

A bass fisherman that doesn't break sticks. ?

Are you from up north somewhere?

I fish in places that many won't try / can't to get thier boat into.

Only to drop baits into busted up docks fallen timber vegetation some people can't conceive of and the fish grow large there .

I have cracked a hull using it to push trees over to access an area. Jumped sandbars on the old Mexico side and that's just bass fishing.

In and around Texas we fish some heavy cover, with heavy line and you have to turn thier heads or there gone.

Sticks break while fishing unless your a careless type and break them by accident.

You want to really break sticks go fishing for redfish or black drum and keep a knife handy to cut line before they spool you and bend the spool. Maybe you are fishing for specs and a drum grabs your catch busts your stick and bends your spool, that's always a bonus day right there.

Go fish out of Cocodri or Dulack, you'll get stuff broke there.

Or maybe it's well below freezing and a smallmouth hits so hard the rod shatters.

Can't belive you fish Toledo Bend and haven't broke rods. I'm not much impressed with bass fishing around the Bossier City area mostly small fish up there.

Rods break all the time unless you can't tie knots or use crappy line.

Are you from up north somewhere?

I fish in places that many won't try / can't to get thier boat into.

Only to drop baits into busted up docks fallen timber vegetation some people can't conceive of and the fish grow large there .

I have cracked a hull using it to push trees over to access an area. Jumped sandbars on the old Mexico side and that's just bass fishing.

In and around Texas we fish some heavy cover, with heavy line and you have to turn thier heads or there gone.

Sticks break while fishing unless your a careless type and break them by accident.

You want to really break sticks go fishing for redfish or black drum and keep a knife handy to cut line before they spool you and bend the spool. Maybe you are fishing for specs and a drum grabs your catch busts your stick and bends your spool, that's always a bonus day right there.

Go fish out of Cocodri or Dulack, you'll get stuff broke there.

Or maybe it's well below freezing and a smallmouth hits so hard the rod shatters.

Can't belive you fish Toledo Bend and haven't broke rods. I'm not much impressed with bass fishing around the Bossier City area mostly small fish up there.

Rods break all the time unless you can't tie knots or use crappy line.

Last edited:

A bass fisherman that doesn't break sticks. ?

Are you from up north somewhere?

I fish in places that many won't try / can't to get thier boat into.

Only to drop baits into busted up docks fallen timber vegetation some people can't conceive of and the fish grow large there .

I have cracked a hull using it to push trees over to access an area. Jumped sandbars on the old Mexico side and that's just bass fishing.

In and around Texas we fish some heavy cover, with heavy line and you have to turn thier heads or there gone.

Sticks break while fishing unless your a careless type and break them by accident.

You want to really break sticks go fishing for redfish or black drum and keep a knife handy to cut line before they spool you and bend the spool. Maybe you are fishing for specs and a drum grabs your catch busts your stick and bends your spool, that's always a bonus day right there.

Go fish out of Cocodri or Dulack, you'll get stuff broke there.

Or maybe it's well below freezing and a smallmouth hits so hard the rod shatters.

Can't belive you fish Toledo Bend and haven't broke rods. I'm not much impressed with bass fishing around the Bossier City area mostly small fish up there.

Rods break all the time unless you can't tie knots or use crappy line.

Last edited:

A bass fisherman that doesn't break sticks. ?

Are you from up north somewhere?

I fish in places that many won't try / can't to get thier boat into.

Only to drop baits into busted up docks fallen timber vegetation some people can't conceive of and the fish grow large there .

I have cracked a hull using it to push trees over to access an area. Jumped sandbars on the old Mexico side and that's just bass fishing.

In and around Texas we fish some heavy cover, with heavy line and you have to turn thier heads or there gone.

Sticks break while fishing unless your a careless type and break them by accident.

You want to really break sticks go fishing for redfish or black drum and keep a knife handy to cut line before they spool you and bend the spool. Maybe you are fishing for specs and a drum grabs your catch busts your stick and bends your spool, that's always a bonus day right there.

Go fish out of Cocodri or Dulack, you'll get stuff broke there.

Or maybe it's well below freezing and a smallmouth hits so hard the rod shatters.

Can't belive you fish Toledo Bend and haven't broke rods. I'm not much impressed with bass fishing around the Bossier City area mostly small fish up there.

Rods break all the time unless you can't tie knots or use crappy line.

Most of my fishing to date was in Mississippi and some in Louisiana. Haven’t fished Texas anything since arriving about 10 years ago. LOL I used to live close to the Pearl river reservoir. Crappie, bream, bass and alligator lol (never fished for alligator, just ran into them often enough).A bass fisherman that doesn't break sticks. ?

Are you from up north somewhere?

I fish in places that many won't try / can't to get thier boat into.

Only to drop baits into busted up docks fallen timber vegetation some people can't conceive of and the fish grow large there .

I have cracked a hull using it to push trees over to access an area. Jumped sandbars on the old Mexico side and that's just bass fishing.

In and around Texas we fish some heavy cover, with heavy line and you have to turn thier heads or there gone.

Sticks break while fishing unless your a careless type and break them by accident.

You want to really break sticks go fishing for redfish or black drum and keep a knife handy to cut line before they spool you and bend the spool. Maybe you are fishing for specs and a drum grabs your catch busts your stick and bends your spool, that's always a bonus day right there.

Go fish out of Cocodri or Dulack, you'll get stuff broke there.

Or maybe it's well below freezing and a smallmouth hits so hard the rod shatters.

Can't belive you fish Toledo Bend and haven't broke rods. I'm not much impressed with bass fishing around the Bossier City area mostly small fish up there.

Rods break all the time unless you can't tie knots or use crappy line.

I am 69, and used to fish a lot. I also used to hunt a lot. North Texas, Dallas area, where I live doesn’t seem to be a sportsman’s paradise by appearances, not to mention that stuff is hard work for me these days

You are correct DFW is not a sportsman's paradise.

It does have a lot of lakes though and I used to fish most of them in local and regional tournaments.

It does have a lot of lakes though and I used to fish most of them in local and regional tournaments.

2x4 on edge are plenty strong enough for a reloading bench. Laminated 2x4 are commonly used for hand tool wood working and see more abuse in a week than a reloading bench will see in its lifetime.

If you have to hammer on it, clamp down or permanently attach an oak strike plate.

A Planer large enough to run a 24 inch wide panel or table top through is going to be north of $3,000.00.

A 2x10 plank top is more than sufficient for reloading of any type. Just use cross stretchers and enough fasteners. I’d also look at anchoring the legs to the floor since the priming process (on the upstroke upward force) is what causes the most movement.

It’s usually not the top that makes a reloading bench suck ass. It’s usually terrible frame and support of the top.

If you have to hammer on it, clamp down or permanently attach an oak strike plate.

A Planer large enough to run a 24 inch wide panel or table top through is going to be north of $3,000.00.

A 2x10 plank top is more than sufficient for reloading of any type. Just use cross stretchers and enough fasteners. I’d also look at anchoring the legs to the floor since the priming process (on the upstroke upward force) is what causes the most movement.

It’s usually not the top that makes a reloading bench suck ass. It’s usually terrible frame and support of the top.

2x10 is very solid choice.A 2x10 plank top is more than sufficient for reloading of any type. Just use cross stretchers and enough fasteners.

I was thinking plane it in sections and then assemble the sections.A Planer large enough to run a 24 inch wide panel or table top through is going to be north of $3,000.00.

TLDR: 0.00% chance I would do a laminated 2x4 top for a reloading bench. Even if the wood was free.I was thinking plane it in sections and then assemble the sections.

I’m going to post my opinion, some presumptions, and some assumptions.

Some questions first:

A) Do you have a lot of clamps?

B) do you have a jointer or at least some way to ensure one flat and straight edge?

C) Do you have roller supports to provide in-feed and out-feed support for the lengths you plan to put through the planer?

D) Do you have a way to surface and flatten the top of the completed table top after it’s planed and glued together?

Your method is sound in theory. in practice it rarely ever works like you wish it would. Even using dominoes, biscuits, or dowels.

If you don’t have true flat and straight bottom reference faces when going through the planer, then all of those irregularities will be transferred into the top. Think cups and bows. So you won’t truly have a flat top.

Ensure you leave each piece about 6” long on each end to account for planer snipe.

I’m a woodworker and there is a 0.00% chance I would do a laminated 2x4 top even for a hand tool wood working bench. They are made that thick so they’re thick enough to work with hold fasts, and withstand the hammering and pounding with chisels and stuff. People use laminated 2x4 because it’s cheaper than a 2.5”-3” solid wood top (depending), and is much more dimensionally stable over time.

Absolutely overkill for a reloading bench. Put your efforts into your frame, and then buy you a nice 1.5” thick butcher block top in the correct size. You’ll be light years ahead that way.

People don’t think making laminated 2x4 bench tops be like it is, but it do.

In that case I guess I’ll just buy butcher block then. I’d rather have hardwood than pine anyhow.TLDR: 0.00% chance I would do a laminated 2x4 top for a reloading bench. Even if the wood was free.

I’m going to post my opinion, some presumptions, and some assumptions.

Some questions first:

A) Do you have a lot of clamps?

B) do you have a jointer or at least some way to ensure one flat and straight edge?

C) Do you have roller supports to provide in-feed and out-feed support for the lengths you plan to put through the planer?

D) Do you have a way to surface and flatten the top of the completed table top after it’s planed and glued together?

Your method is sound in theory. in practice it rarely ever works like you wish it would. Even using dominoes, biscuits, or dowels.

If you don’t have true flat and straight bottom reference faces when going through the planer, then all of those irregularities will be transferred into the top. Think cups and bows. So you won’t truly have a flat top.

Ensure you leave each piece about 6” long on each end to account for planer snipe.

I’m a woodworker and there is a 0.00% chance I would do a laminated 2x4 top even for a hand tool wood working bench. They are made that thick so they’re thick enough to work with hold fasts, and withstand the hammering and pounding with chisels and stuff. People use laminated 2x4 because it’s cheaper than a 2.5”-3” solid wood top (depending), and is much more dimensionally stable over time.

Absolutely overkill for a reloading bench. Put your efforts into your frame, and then buy you a nice 1.5” thick butcher block top in the correct size. You’ll be light years ahead that way.

People don’t think making laminated 2x4 bench tops be like it is, but it do.

A piece of hardwood glued to 2x4 would be nice.

Thought we were being smart and tied it into the wall joists. Strong but picked up vibrations in the rest of the house that the digital scales didn't like.

Plywood is strong but fugly my son painted the dang stuff.

We used thick plywood for tops and shelves . 4x4's for legs on my sons bench it was a monster.If you have to hammer on it, clamp down or permanently attach an oak strike plate.

Thought we were being smart and tied it into the wall joists. Strong but picked up vibrations in the rest of the house that the digital scales didn't like.

Plywood is strong but fugly my son painted the dang stuff.

Last edited:

For the cost of the 2x4 to make a top that's 24" wide , and the labor/time it takes to do it, it makes much more sense to just buy a thick butcher block. It doesn't matter what species of wood it is. You can get 10' sections of it for like $200 here in cheaper woods. That's about twice what your material would cost to do 2x4 but you'd have a good flat top. It's the finishing that makes butchers block expensive to do, and you can definitely do that. Use some poly and light sand between coats. Do 3 coats and your good.In that case I guess I’ll just buy butcher block then. I’d rather have hardwood than pine anyhow.

I think all of my tops which was 3 pcs.(2@ 10' and 1@12'), it was like $800 with tax and cheaper wood would save you a few hundred if you bought the same sizes.

Damn. A 10’ section runs over $400 everywhere I’ve looked.For the cost of the 2x4 to make a top that's 24" wide , and the labor/time it takes to do it, it makes much more sense to just buy a thick butcher block. It doesn't matter what species of wood it is. You can get 10' sections of it for like $200 here in cheaper woods.

I thought I'd peek at this thread even though the idea of a "reloading room" isn't practical for me. I use a space in the garage that's shared with the general-purpose tool chests, the chemical/fluids/paint cabinet and some wire shelving for auto and household tools (jack stands, skilsaw, drill, wheel chocks, grease gun etc.)

Press Stand in lieu of Bench

I read a lot about people striving to build monster benches and benchtops that don't flex. I've never tried it. I use a press stand and would never go any other way.

I bought a 10' piece of 2" steel pipe at the home store and had it cut and threaded with their Rigid machine at several lengths. I bought flanges for each end. One flange I bolted to the concrete floor. The key here is to drill out the flange for larger bolts or it will flex too much. I was able to bolt my single-stage press directly to the flange on the top, but it would be easy to bolt a plate to the flange and then mount any press or a press-plate system on there.

I still have another two pieces from the 10-footer. I'm going to install another stand for a vise, and I could definitely use the third but might not have the place for it.

When I cut the 10-footer, I cut three different lengths of pipe so I could try them and find the height for the press that I liked best. I chose the highest stand that puts my press a little higher than it would be with a press riser on a bench.

I also have a Lee tri-pod stand with a heavy concrete weight on the bottom. I like it because it holds the Akro bins nicely, but otherwise it's too short/low. It's sturdier than a lot of bench setups, but I wouldn't want to use it to resize rifle brass. I just use it to run a Lee APP Deluxe or a ABLP progressive to perform light operations like resizing and flaring handgun brass, de-capping, and priming. I think Lee made it so low because they wanted the legs to ship via regular carrier. The wide base has some advantages over the narrower pipe flange.

Ideally, I'd have larger diameter pipe and flanges, maybe 4" or 6". I also considered building stands using 12" concrete-filled Sono-Tubes. Grizzly sells a nice steel bench grinder stand, but it would be too low.

In any case, I don't envy any bench.

Press Stand in lieu of Bench

I read a lot about people striving to build monster benches and benchtops that don't flex. I've never tried it. I use a press stand and would never go any other way.

I bought a 10' piece of 2" steel pipe at the home store and had it cut and threaded with their Rigid machine at several lengths. I bought flanges for each end. One flange I bolted to the concrete floor. The key here is to drill out the flange for larger bolts or it will flex too much. I was able to bolt my single-stage press directly to the flange on the top, but it would be easy to bolt a plate to the flange and then mount any press or a press-plate system on there.

I still have another two pieces from the 10-footer. I'm going to install another stand for a vise, and I could definitely use the third but might not have the place for it.

When I cut the 10-footer, I cut three different lengths of pipe so I could try them and find the height for the press that I liked best. I chose the highest stand that puts my press a little higher than it would be with a press riser on a bench.

I also have a Lee tri-pod stand with a heavy concrete weight on the bottom. I like it because it holds the Akro bins nicely, but otherwise it's too short/low. It's sturdier than a lot of bench setups, but I wouldn't want to use it to resize rifle brass. I just use it to run a Lee APP Deluxe or a ABLP progressive to perform light operations like resizing and flaring handgun brass, de-capping, and priming. I think Lee made it so low because they wanted the legs to ship via regular carrier. The wide base has some advantages over the narrower pipe flange.

Ideally, I'd have larger diameter pipe and flanges, maybe 4" or 6". I also considered building stands using 12" concrete-filled Sono-Tubes. Grizzly sells a nice steel bench grinder stand, but it would be too low.

In any case, I don't envy any bench.

I did HD butcher block on top of Lowe’s in stock cabinets. I was concerned the cabinets couldn’t support the presses and motions long term so I made 2x4 frames ( covered with matching dishwasher panels ) that do most of the supporting for the tops. I also made another frame under the bottom of the cabinets that supports the weight on the bottom shelf for projectiles and stuff.HD has two or three options under $400

I would just go with a couple of 10 or 12 inch wide oak. You can glue/screw a couple more sheets under. There won’t be any deflection that way as long as you have the sheets supported with strong and supported legs.

I have something like 1.5” pine that had a slight deflection when pressing. I stuck (glue and screw) a 1/2” or 3/8” sheet of oak under the presse area and no deflection whatsoever. I do need to anchor the entire table better, though.

I have something like 1.5” pine that had a slight deflection when pressing. I stuck (glue and screw) a 1/2” or 3/8” sheet of oak under the presse area and no deflection whatsoever. I do need to anchor the entire table better, though.

Although my presses are on stands and not benches, I do have some work surfaces. I have a large steel desk that I found on the roadside. I'm not normally a scrounger, but this is a nice steel desk made in the 70's. It's at least 200 pounds empty. At one point, I put it in front of the house with a sign "free" on it, but nobody who wanted it could move it, so I brought it in and adopted it despite not really having the space for it (it's huge).

The reason I want to share this with you is because of the unique surface I put on it. The desk itself has a steel top with a woodgrain melamine surface (not particleboard, but melamine laminated to the steel).

Rubber Stall Mats

On the floor, I put those thick rubber pads for inside a horse's stall. That's where I got the idea to put one over the desk surface. It works great. It very damping of any vibrations. Nothing slides on it or even rolls. It's firm enough that I can stand brass on it (though I would normally use a case block). Whether I drop something on the desk or the floor, the rubber prevents damage more than a hard surface -- think about dropping calipers for example or a die.

The rubber stall mats have been pretty durable and I've had them for almost 5 years now. They might not be resistant to all chemicals, so I would be cautious about cleaning solvent spills or over-spray. To clean the stall mats, I use a shop-vac and an air-compressor blow-gun.

Rubbermaid Cart

I use solvents on a different surface. I use a Rubbermaid Commercial polymer cart. The wet tumbler (Rebel 17) and the dry tumbler (Lyman Magnum) is in the bottom of it, and the top is for stripping and cleaning. The deep sides keep liquids, solvents, and loose parts contained. It also isolates the vibration from the tumblers and it can be rolled outside.

The reason I want to share this with you is because of the unique surface I put on it. The desk itself has a steel top with a woodgrain melamine surface (not particleboard, but melamine laminated to the steel).

Rubber Stall Mats

On the floor, I put those thick rubber pads for inside a horse's stall. That's where I got the idea to put one over the desk surface. It works great. It very damping of any vibrations. Nothing slides on it or even rolls. It's firm enough that I can stand brass on it (though I would normally use a case block). Whether I drop something on the desk or the floor, the rubber prevents damage more than a hard surface -- think about dropping calipers for example or a die.

The rubber stall mats have been pretty durable and I've had them for almost 5 years now. They might not be resistant to all chemicals, so I would be cautious about cleaning solvent spills or over-spray. To clean the stall mats, I use a shop-vac and an air-compressor blow-gun.

Rubbermaid Cart

I use solvents on a different surface. I use a Rubbermaid Commercial polymer cart. The wet tumbler (Rebel 17) and the dry tumbler (Lyman Magnum) is in the bottom of it, and the top is for stripping and cleaning. The deep sides keep liquids, solvents, and loose parts contained. It also isolates the vibration from the tumblers and it can be rolled outside.

Either a single or better a double piece of 3/4” 7 ply plywood over a strong frame of 2x4’s makes a great work top. Not pretty but solid. However what I found on my shop workbench which is now 16 years old and still solid, is that you should screw in the top to the 2x4’s. On this table, I glued it on and after years of every kind of work on the bench it sorely needs a replacement. however, adding another board on top would raise it higher than the saws. So, the only answer is to cut down the legs. Been better to screw it on and I could screw it off when I am ready to replace.A piece of hardwood glued to 2x4 would be nice.

We used thick plywood for tops and shelves . 4x4's for legs on my sons bench it was a monster.

Thought we were being smart and tied it into the wall joists. Strong but picked up vibrations in the rest of the house that the digital scales didn't like.

Plywood is strong but fugly my son painted the dang stuff.

Table is still solid, but the top is really rough, with gouges and paint build up, soaked in grease and oil, its just not what I need to do decent quality woodwork.

I see ‘em now. Could’ve sworn they were $400 or more. Maybe I had been looking somewhere else.HD has two or three options under $400

We do have a good source. Southestern Salvage. They got into the butcher block 10 ish years ago and have grown that part of their business a lot and now have quite a selection for a good price.Damn. A 10’ section runs over $400 everywhere I’ve looked.

Currently building another reloading room in the unfinished part of the basement. The wife got an at home job and I gave her my current room in the finished part of the house. What your some successes and fails with lighting? I have exposed joists and running a new 20amp circuit just for this room. Ought to be able to accomodate about any lighting I need.

It wont be unfinished anymore. Im finishing a corner about 12x12 its the dead end of the HVAC so ill jerry it up and drop a return on the floor and a vent in the ceiling. Im not against LED strip lights, easy to install and plenty bright, just wondered about more finished options. Thought about 2 runs of leds in the joists with diffisers.

Attachments

I would recommend LED lighting. Many are adjustable regarding the color and you might find a sunlight type natural color to be to your liking. At any rate, adjustable gives you options, and uses very little electricity. Home Depot has lots of options at reasonable prices. Amazon would be more cost effective. Just know what you are looking for.Currently building another reloading room in the unfinished part of the basement. The wife got an at home job and I gave her my current room in the finished part of the house. What your some successes and fails with lighting? I have exposed joists and running a new 20amp circuit just for this room. Ought to be able to accomodate about any lighting I need.

LED seems to be the best and least issues with a scale. I wouldn't put any light too close to the scale though. I've not had any issues I know of using led lights. With open joists, you could do can lights or do led garage type lights, like the 2'x4' florescent lights we used to use but they are LED.Currently building another reloading room in the unfinished part of the basement. The wife got an at home job and I gave her my current room in the finished part of the house. What your some successes and fails with lighting? I have exposed joists and running a new 20amp circuit just for this room. Ought to be able to accomodate about any lighting I need.

Will you ever put a ceiling in it? If so, might want to consider that but otherwise any led light set up should work well.

If you will be putting a sheet rock ceiling then you could go ahead snd put the can lights in and then just sheet rock whenever you decide to do it. Of it's a drop ceiling then the can housing hangs on the ceiling tile so you'd need the grid in first.

In a basement I would worry more about air "dumping" out of the HVAC system vents when it cycles off. Or rolling down the stairs same thing.

The last place my bench was had Central ac. All it took was a small air diverter on the vent and the trickle ran fine when the ac was running.

Closing the vent was a bad option in the Texas summers.

Each time the ac would cycle off there would be a flood of cold air dropping down onto the bench instead of it blowing gently around the room.

Lights and electronics did little to change the scales we tested trying to troubleshoot this. Strong vibration would scramble it momentarily even ceiling fans on low or medium had little effect.

But dear sweet little white baby Jesus two degree drop or heaven forbid three degrees and your dead in the water.

Not just once but twice as it warms back up and stabilizes.

Keep an eye on your " empty" scales negative reading when you lift the pan off. It should remain constant.

The last place my bench was had Central ac. All it took was a small air diverter on the vent and the trickle ran fine when the ac was running.

Closing the vent was a bad option in the Texas summers.

Each time the ac would cycle off there would be a flood of cold air dropping down onto the bench instead of it blowing gently around the room.

Lights and electronics did little to change the scales we tested trying to troubleshoot this. Strong vibration would scramble it momentarily even ceiling fans on low or medium had little effect.

But dear sweet little white baby Jesus two degree drop or heaven forbid three degrees and your dead in the water.

Not just once but twice as it warms back up and stabilizes.

Keep an eye on your " empty" scales negative reading when you lift the pan off. It should remain constant.

Everything you said was spot on. Particularly the final paragraph. Saved the best for last. This is critical to knowing drift or charge to charge accuracy and repeatability. An LED light won’t do anything to a scale unless it is resting on it lol. My wife loves ceiling fans, particularly on high speed. I have to charge my cases when she isn’t around to make sure she isn’t blowing air on my scales and I turn off the a/c because otherwise, there will be problems lolKeep an eye on your " empty" scales negative reading when you lift the pan off. It should remain constant.

Never quite reasoned it out the way you did, I was a bit more simplistic but it was all the same outcome.

Perfect!

Man, can you adopt me? I am only 70, andnI don’t eat much….I'm lucky that my reloading room is separated from the rest of the house. We also don't have central air. It's all radiant water. I close that door to the room and it's draft free. Warms and cools through the rest of the house passively. Warm in the winter and nice and cool in the summer.

Where the heck do you live? That sounds wonderful and very efficient. Texas heat here.

The emf for LED lights is virtually non-existent at 24” at most. Many become background noise level at 12”.Everything you said was spot on. Particularly the final paragraph. Saved the best for last. This is critical to knowing drift or charge to charge accuracy and repeatability. An LED light won’t do anything to a scale unless it is resting on it lol. My wife loves ceiling fans, particularly on high speed. I have to charge my cases when she isn’t around to make sure she isn’t blowing air on my scales and I turn off the a/c because otherwise, there will be problems lol

Never quite reasoned it out the way you did, I was a bit more simplistic but it was all the same outcome.

Perfect!

LED seems to be the best and least issues with a scale. I wouldn't put any light too close to the scale though. I've not had any issues I know of using led lights. With open joists, you could do can lights or do led garage type lights, like the 2'x4' florescent lights we used to use but they are LED.

Will you ever put a ceiling in it? If so, might want to consider that but otherwise any led light set up should work well.

If you will be putting a sheet rock ceiling then you could go ahead snd put the can lights in and then just sheet rock whenever you decide to do it. Of it's a drop ceiling then the can housing hangs on the ceiling tile so you'd need the grid in first.

There will be a ceiling either tonight or tomorrow, depending on the lights i decide on. Definately will be going LED trying to decide between strips or cans now.In a basement I would worry more about air "dumping" out of the HVAC system vents when it cycles off. Or rolling down the stairs same thing.

The last place my bench was had Central ac. All it took was a small air diverter on the vent and the trickle ran fine when the ac was running.

Closing the vent was a bad option in the Texas summers.

Each time the ac would cycle off there would be a flood of cold air dropping down onto the bench instead of it blowing gently around the room.

Lights and electronics did little to change the scales we tested trying to troubleshoot this. Strong vibration would scramble it momentarily even ceiling fans on low or medium had little effect.

But dear sweet little white baby Jesus two degree drop or heaven forbid three degrees and your dead in the water.

Not just once but twice as it warms back up and stabilizes.

Keep an eye on your " empty" scales negative reading when you lift the pan off. It should remain constant.

Thanks for the observation, the HVAC vent will be away from the scale so draft wont be an issue, have been dealing with temp swings in the current room too as its just 15' away. My best solution so far is to turn the recirculation fan on when im loading, it helps keep the temp more consistant.

I think the air movement is way bigger issue than temp fluctuations but ideally you'd like to eliminate both of course.There will be a ceiling either tonight or tomorrow, depending on the lights i decide on. Definately will be going LED trying to decide between strips or cans now.

Thanks for the observation, the HVAC vent will be away from the scale so draft wont be an issue, have been dealing with temp swings in the current room too as its just 15' away. My best solution so far is to turn the recirculation fan on when im loading, it helps keep the temp more consistant.

Cans are a lot nicer imo. Also, you can get dimmable led cans wither with a housing or you can use "can-less" which don't have a housing. This gives you the ability to just run the wire and know where it is, then cut the can holes where you want them to be vs having to put the housing in the right location before sheet rock.

That may not matter to you and if not, I'd use a "new constitution can" which is a housing and a led trim. Whe ever they do go out you just replaced the trim. However, if it's beneficial to choose the exact can location after sheet rock, go can-less. We really only use canless when there's a joist in the way of where we need it, or if it's a special ceiling (like T&G) or some other reason we would want to space the can trim perfectly so it looks perfect.

Just plan your can placement so you have lights over the bench and spaced out from the wall enough to accommodate cabinets on the wall, so a light doesn't end up half over a cabinet , and you will be good. Of course if you aren't being inspected, just run a "uh oh wire" between two joist where you want it and back to your switch box, and if you don't need it don't tie it in. If you do need it, you've got it and can put can less in after sheet rock without issue.

The only thing to watch out for is that often the canless cans baffle or trim won't match the led trim for a new construction can, but you certainly can get them that do match, just have to pay attention to it.

Also just fyi- often the can less hole size that you need to cut out is not the same exact hole size as you may think so make sure you have the right hole saw before you cut it out or you will be putting "goof rings" on all your cans

SweetGot the room mostly done today. Just a little clean up and mirroring the shelves on the other side of the upper cabinet. Might do something a bit different there for a building cleaning station.View attachment 8336245View attachment 8336258

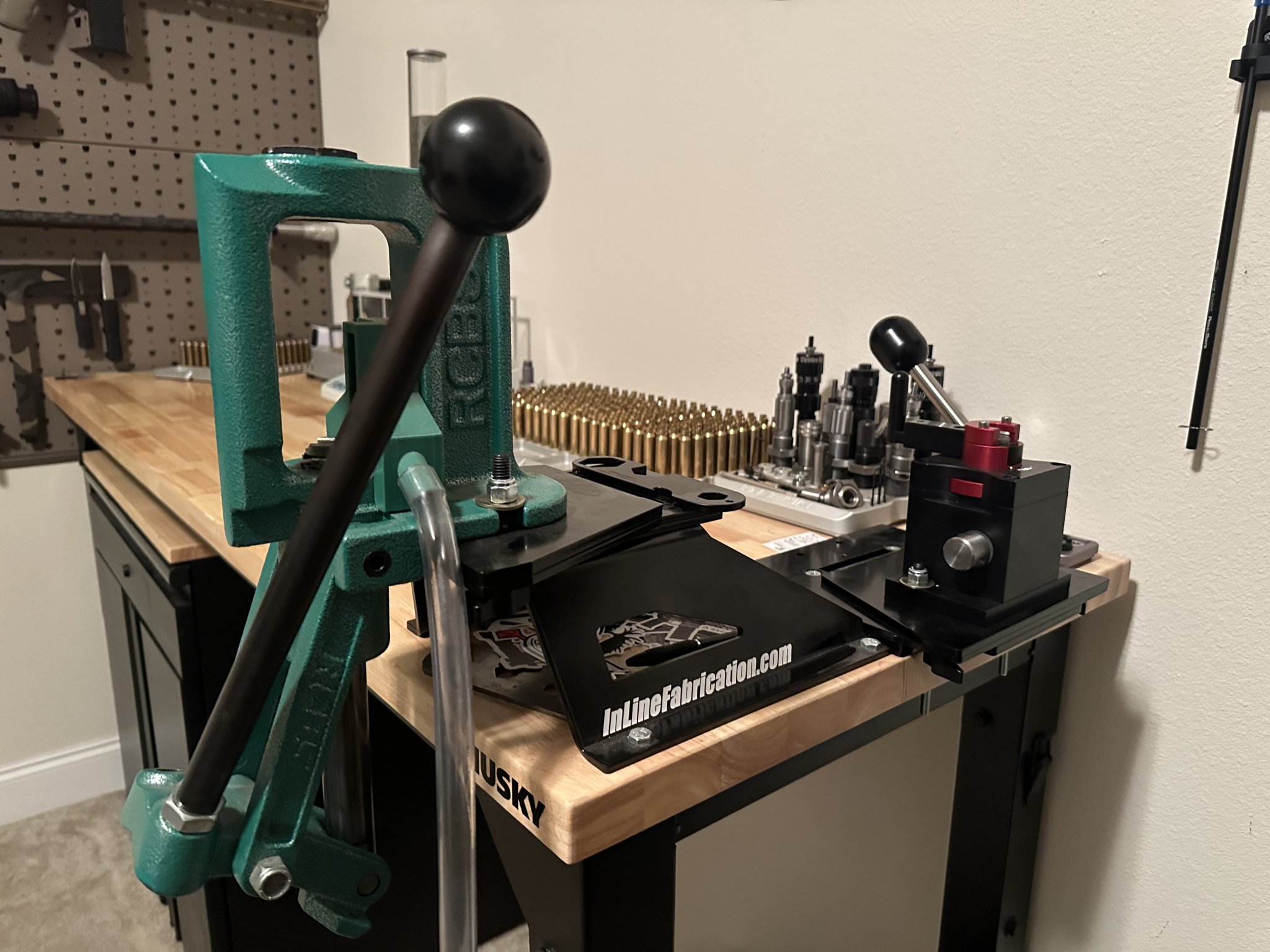

These quick ultra mounts from inline fab are awesome and he has most stuff already designed the plates. I can easily move any of my tools anywhere depending on what I’m doing

Waiting on one more for my zero currently.

Waiting on one more for my zero currently.

Attachments

I am sort of embarrassed to show mine after how neat everyone else's is, but I know where things are, and it is organized for how my brain works. I just put in the second bench with 650. Finally have one setup for large and small primers, lot easier to reload and not be changing between them. I wish I didn't have to have all my electrical running off of one outlet through two surge protectors, but I don't know what else to do. Need better lighting, and to change the placement of them.

This bench is the third I built, and is really stable, just wish it was longer.

Fourth and last bench I built. Canabalized wood from my second bench for some of it. And it has the new (to me) second of my 650s. Just got done trimming a couple thousand pieces of 556 on it. Love the Dillon rt1500!

This bench is the third I built, and is really stable, just wish it was longer.

Fourth and last bench I built. Canabalized wood from my second bench for some of it. And it has the new (to me) second of my 650s. Just got done trimming a couple thousand pieces of 556 on it. Love the Dillon rt1500!

Where did you get that gray, vented cabinet under the bench?Got the room mostly done today. Just a little clean up and mirroring the shelves on the other side of the upper cabinet. Might do something a bit different there for a building cleaning station.View attachment 8336245View attachment 8336258

I get to claim the small excuse of a basement at the new house, so things will be rearranged. Inline fab has been a life saver for pretty much everything I could ask for up to this point. However, I started 3d printing my own toolhead holders because 20 bucks each stacks up quickly.

Attachments

My work top is double 3/4" plywood with 4 x 4 posts and 2 x 6 framing.

First layer of plywood was screwed down. Then a coating of wood glue.

Second layer (work top) was installed and stapled on the underside with 1 1/4" staples. No fasteners exposed on the top surface. Works very well.

First layer of plywood was screwed down. Then a coating of wood glue.

Second layer (work top) was installed and stapled on the underside with 1 1/4" staples. No fasteners exposed on the top surface. Works very well.

Attachments

It was a used laptop charging station from the local school. They were upgrading and I picked it up cheap.Where did you get that gray, vented cabinet under the bench?

Similar threads

- Replies

- 66

- Views

- 3K

- Replies

- 103

- Views

- 5K