Been fighting it for years and just dealt with it. Makes me think about what an old man told me yrs ago. A young man will work with a pebble in his shoe. An old man will stop and remove it.

Guess I'm old enough to stop and remove the pebble. Or at least try.

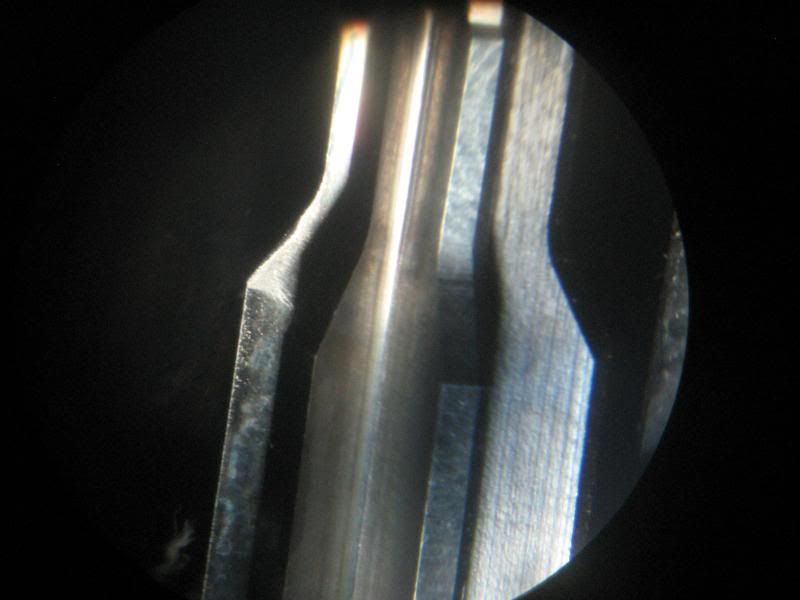

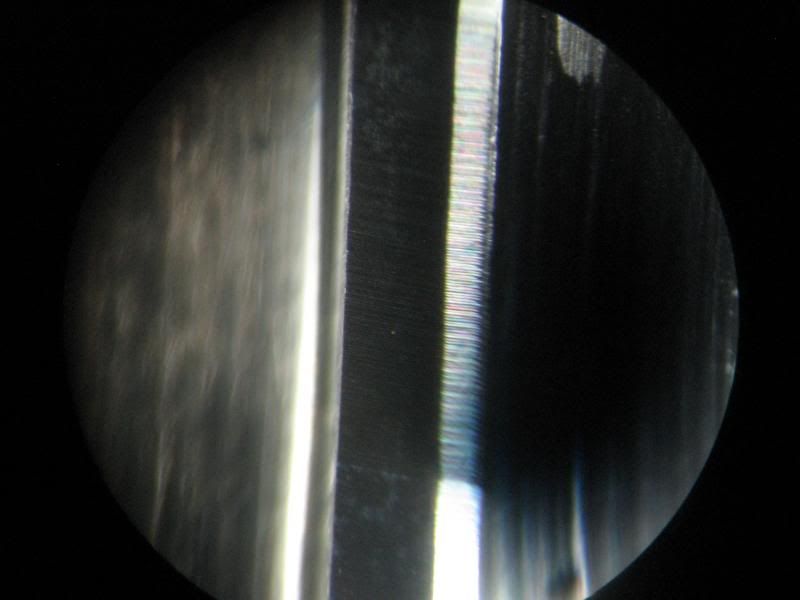

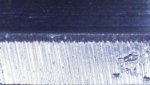

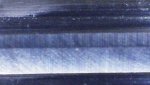

Most reamers I've used cut on 1. 2 or 3 flutes on the shoulder. This results in a buildup of metal on the flutes which causes grooves being cut in the shoulder of the chamber. (or maybe it just my cutting fluid) To combat this, I use a ceramic stone to remove the buildup when I get to the last .050" or so. PITA

Anybody got any tricks or magic oil to get the pebble out of my shoe?

Guess I'm old enough to stop and remove the pebble. Or at least try.

Most reamers I've used cut on 1. 2 or 3 flutes on the shoulder. This results in a buildup of metal on the flutes which causes grooves being cut in the shoulder of the chamber. (or maybe it just my cutting fluid) To combat this, I use a ceramic stone to remove the buildup when I get to the last .050" or so. PITA

Anybody got any tricks or magic oil to get the pebble out of my shoe?