Some may recall earlier this year when the rumors were flying that I'd blown my face off after an action decided to disassemble itself very rapidly.

So, we made some changes in the shop, and I'm changing it again.

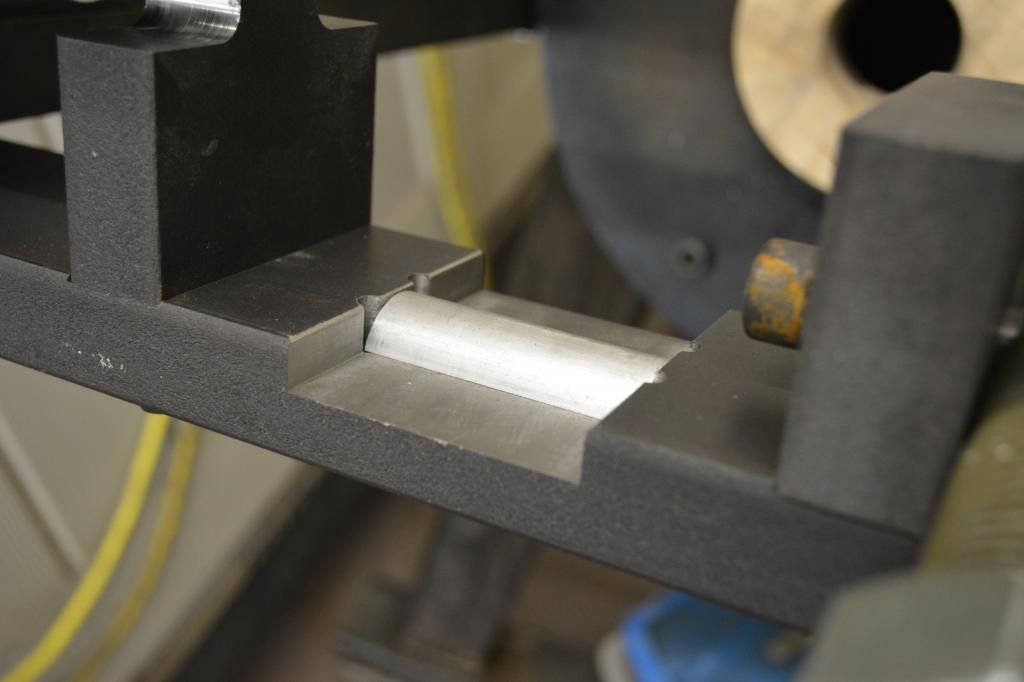

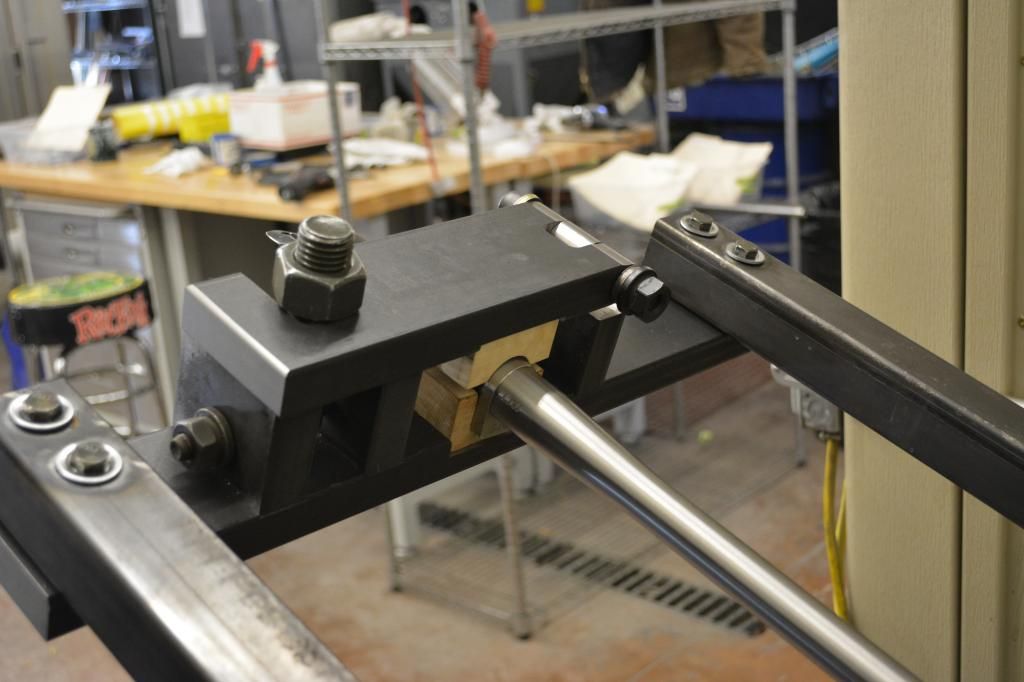

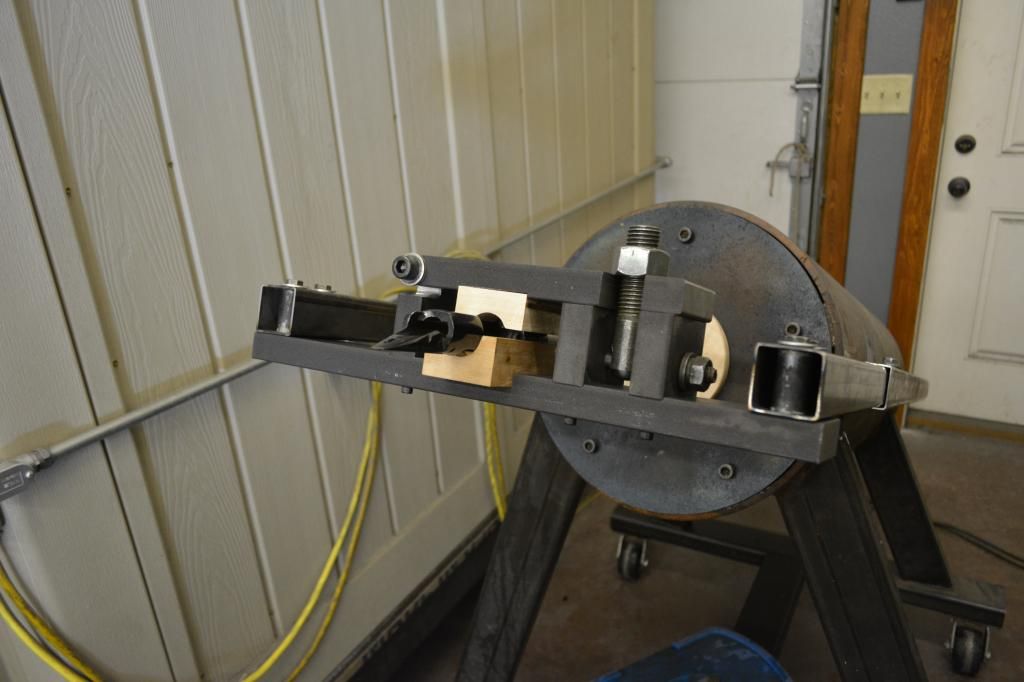

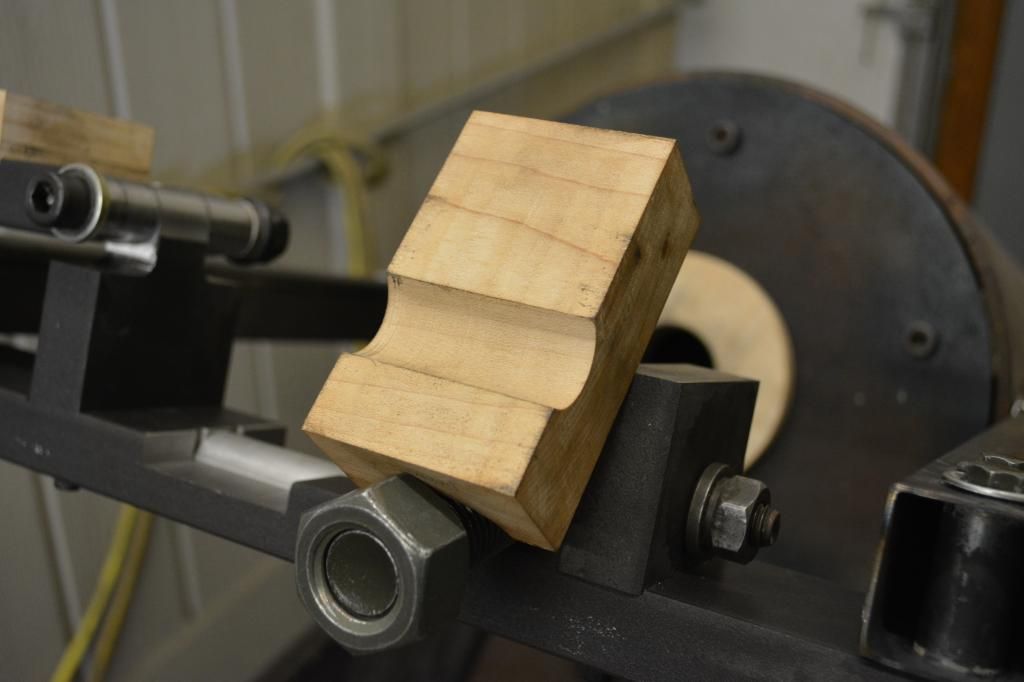

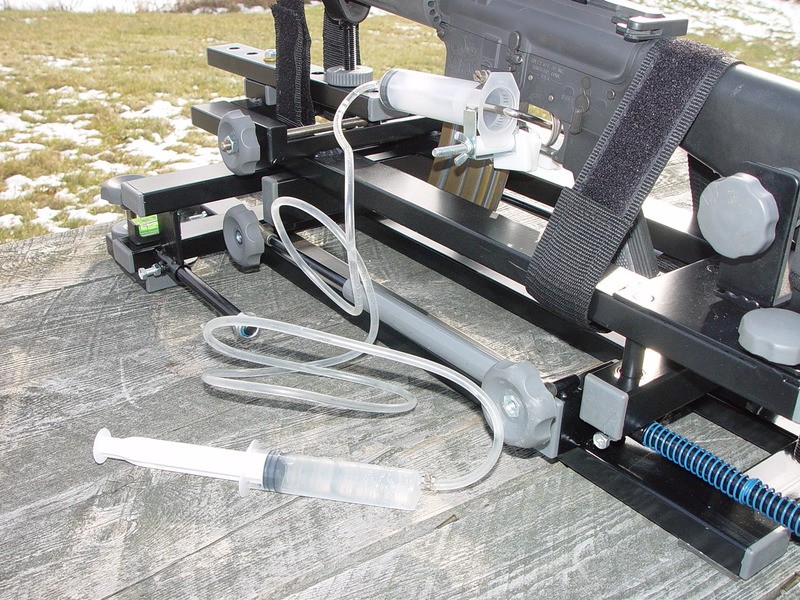

I've built a "device". It's a recoil absorbing vice assembly that allows us to fixture the B/A with the muzzle fully contained in the test barrel.

What my intentions are now is to obtain a remote hand held momentary on/off switch with a master power (on/off toggle). Needs around a 15' cord I'm guessing. What I envision is a simple hand held cylinder with an aircraft style toggle cover, flip the cover, turn on the toggle and that powers up ol betty. Then when your ready to go bang, you press the button which activates a solenoid mounted to a bracket on a jewel trigger. (thinking Jewel only cause we've been using one that I dropped and broke the trigger shoe on about 5 years ago. Works great for testing here in the shop and they already have screw holes on the sides for attaching a simple bracket.)

Figure a plain old trunk solenoid off an old GM car should work great with a pair of 9V's wired in a series circuit.

My vice setup has a blast shield made of steel that clamshells over the action. With a 15' cord the "Guinea pig" running the thing can move behind a wall. Future orbital fractures and torn retinas avoided!

Pretty excited about it and I know how to wire the thing up so it's "Chad Proof". Just don't know the terminology to go sourcing parts. Closest I've found is a remote starter switch from Matco, but it lacks the master power function. I did find a nice piece made in Germany, but that damn thing is $1200.00!

I think I can get it figured out for about 10% of that... Even if I have to buy raw components and machine the handle from scratch. -which I may end up doing...

Any help is appreciated.

Thanks.

Chad

So, we made some changes in the shop, and I'm changing it again.

I've built a "device". It's a recoil absorbing vice assembly that allows us to fixture the B/A with the muzzle fully contained in the test barrel.

What my intentions are now is to obtain a remote hand held momentary on/off switch with a master power (on/off toggle). Needs around a 15' cord I'm guessing. What I envision is a simple hand held cylinder with an aircraft style toggle cover, flip the cover, turn on the toggle and that powers up ol betty. Then when your ready to go bang, you press the button which activates a solenoid mounted to a bracket on a jewel trigger. (thinking Jewel only cause we've been using one that I dropped and broke the trigger shoe on about 5 years ago. Works great for testing here in the shop and they already have screw holes on the sides for attaching a simple bracket.)

Figure a plain old trunk solenoid off an old GM car should work great with a pair of 9V's wired in a series circuit.

My vice setup has a blast shield made of steel that clamshells over the action. With a 15' cord the "Guinea pig" running the thing can move behind a wall. Future orbital fractures and torn retinas avoided!

Pretty excited about it and I know how to wire the thing up so it's "Chad Proof". Just don't know the terminology to go sourcing parts. Closest I've found is a remote starter switch from Matco, but it lacks the master power function. I did find a nice piece made in Germany, but that damn thing is $1200.00!

I think I can get it figured out for about 10% of that... Even if I have to buy raw components and machine the handle from scratch. -which I may end up doing...

Any help is appreciated.

Thanks.

Chad

Last edited: