Your fired brass looks perfectly normal.... well kind of... ( normal for a bolt gun, Lol ) ... Anyone else notice the

complete lack of ejector smear, or typical extractor marks in the photos ?

Those mentioned marks are "the norm" when it comes to even my tweaked Large Frame AR's.

IMHO, that alone implies "no gas, or so danged little that it is meaningless" is making it to the bolt for proper function.

Did you ever check for gas leaks at the gas key ? Or missing gas rings ? .. or a blocked gas tube ?

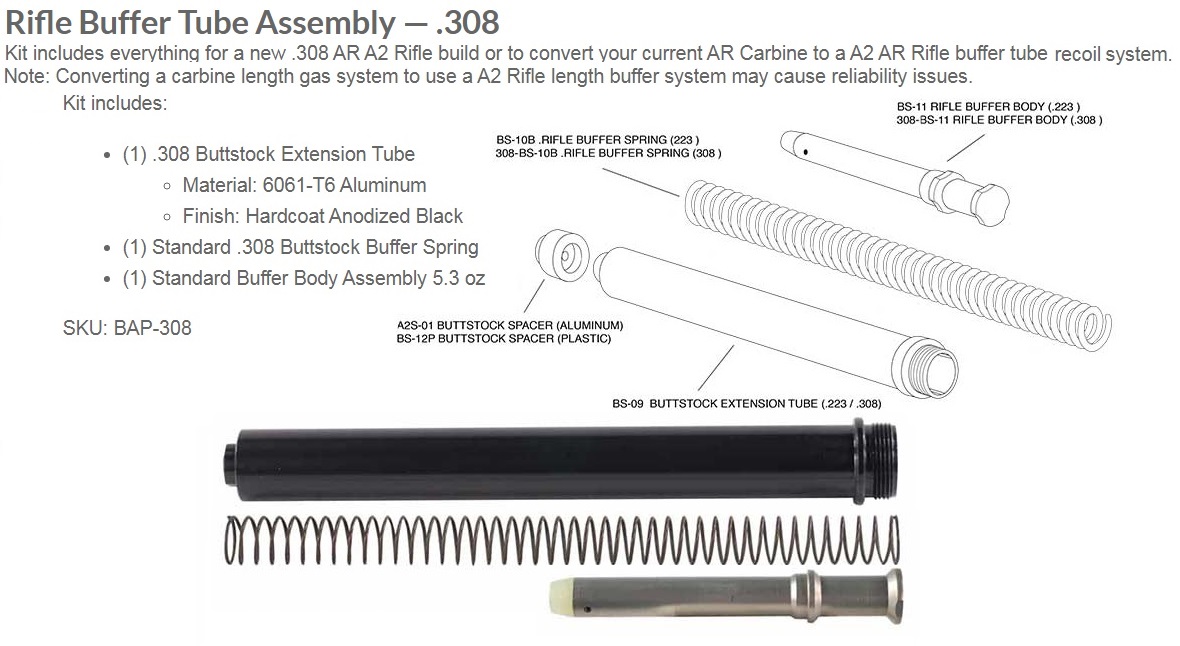

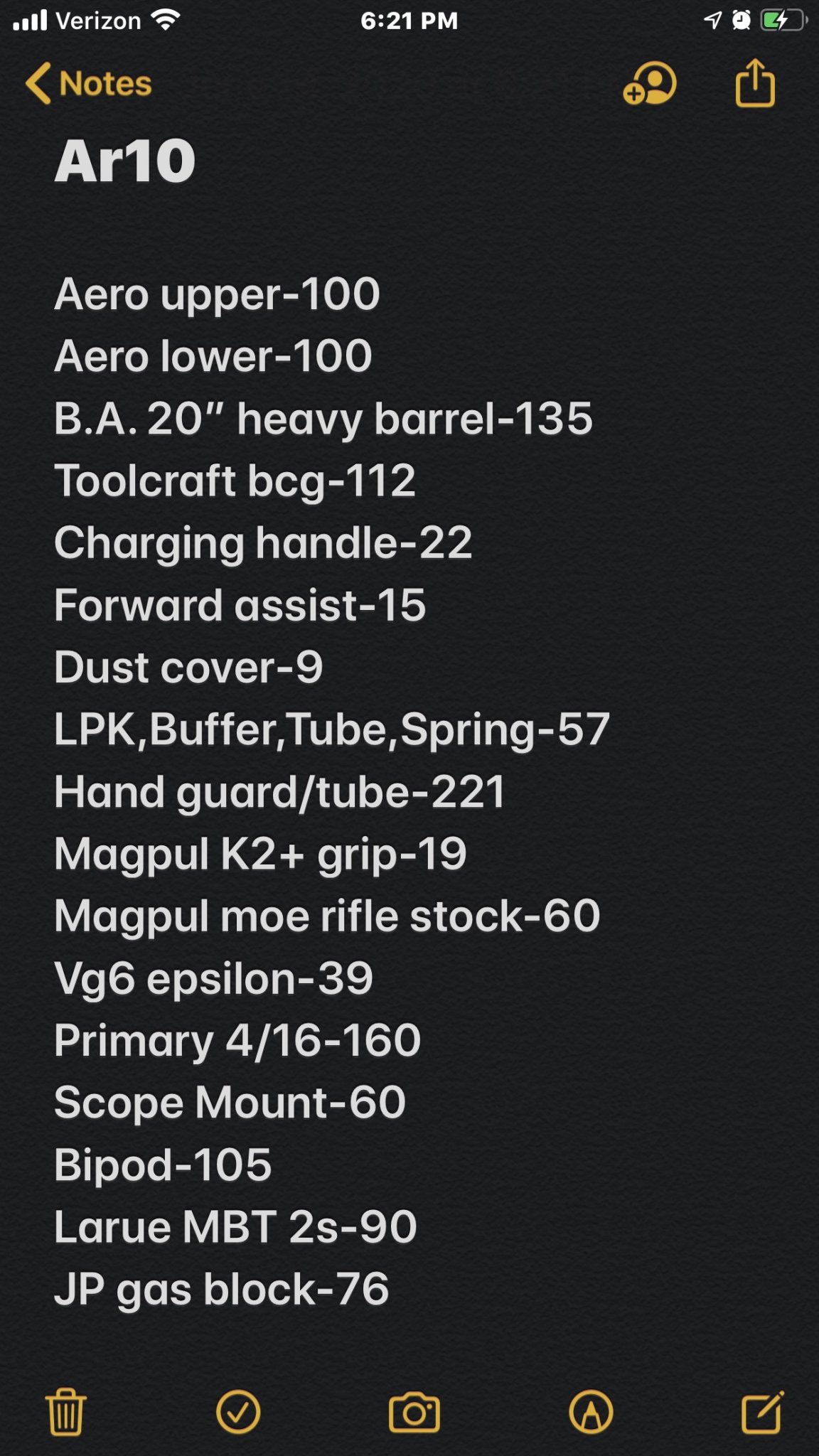

I am tending to think a blocked gas tube or even the JP gas block ... or something in front of the gas key.

For the OP, and I realize you may not want to hear this.... but I would remove the gas block with the gas tube still installed, look for gas "burn" marks on the barrel, at the gas port ( that will show 100% if the alignment is correct and post PICS !

so we all can see it is properly aligned, and eliminate the slightest doubt. )

Then blow through the shoulder end of the gas tube with the GB, adjusted wide open.

"If" you have another gas tube and GB available compare the 2 against each other.

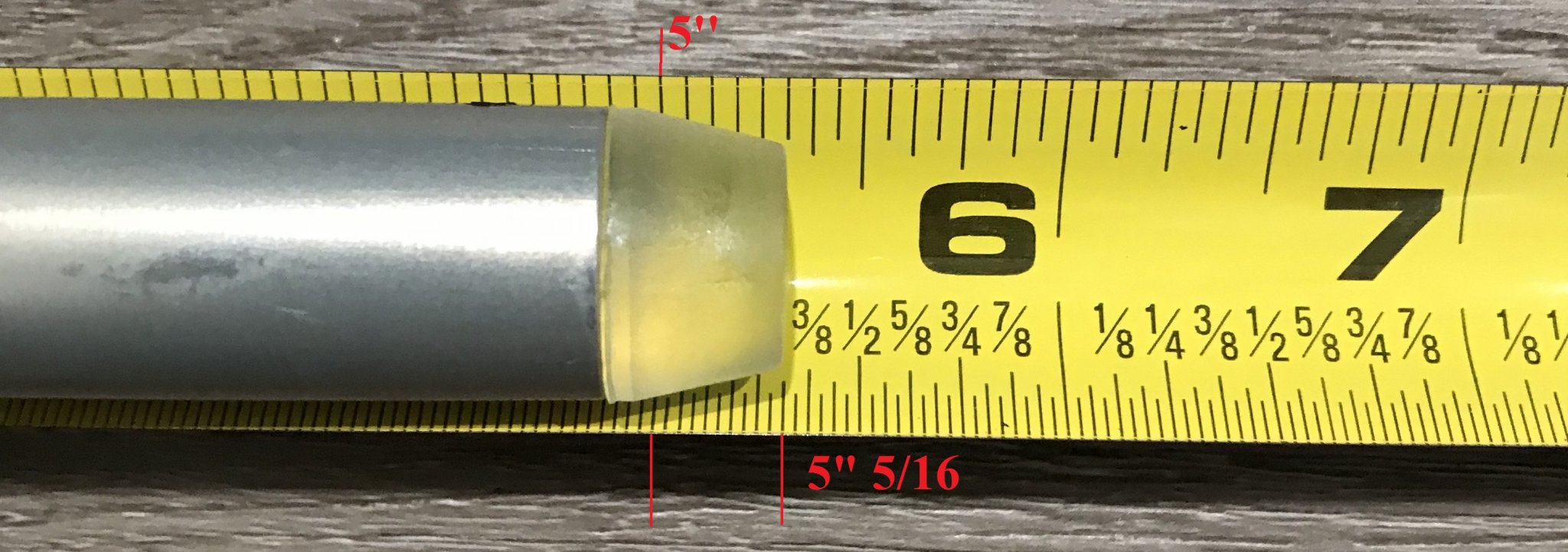

Using the smooth part of a drill bit , inserted into the gas port.... ( doesn't have to be a perfect fit we are looking for a "this is to big, and that is to small ) let us know what fit and what didn't. That will give us an idea of the gas port size.

How dirty is the upper CH channel ? Looking for normal exhaust gas filth... if the gas is flowing... there should be filth.

Brass wise......No odd scuff marks. So chamber is smooth. Winchester primers look a little flat for my tastes, but ....

The 2 lines on the neck are normal, and will smooth away after enough rounds fired through it.