Several hundred steel targets from prairie dogs to gongs. Every hundred yards out to 880. It's a good spotThat’s a nice spot. Most ranges around here are “sand pits” of sorts

just some generic stuff not to make you write a essay

is it all steel or can you put paper or the closer ranges

Min max range

What are the distances set at...every 100 yards on the dot or misc because if the landscape

I looked online for a bit, either my Google Fu dumped me or I mused it.

thanks

Brian

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hoplite Arms

- Thread starter THEIS

- Start date

- Status

- Not open for further replies.

When the high pressure cartridges are used will they require stronger/different spec suppressors or will normal suppressors work due to the muzzle having less pressure than the chamber?

Hi,

I am sure they will require specifically designed suppressors for the High Pressure cartridges but to be upfront and honest we are not really focused on that aspect yet as it would be putting the cart before the horse sorta to speak.

Hoplite Arms is focusing on the weapon systems and the cartridge systems at this point in time.

Currently the suppressor experts do not have a reason to design and manufacturer to xyz pressures because they are not achievable in the industry so we cannot really blame them for not having an off the shelf high pressure capable suppressor ready.

Currently Hoplite Arms is tunnel vision with getting our weapon systems (All 3 models) into the production part of the business plan and same with our HP ammunition division...O and setting up a training division, lol.

After that we will have enough time to essentially push the suppressor manufacturers to the front burner for HP capable suppressor.

A wise man once said "surround yourself with people that are smarter than you are"....and in the reference of suppressor; we will definitely be reaching out in more detail to guys like Ray at TBAC.

Sincerely,

Theis

Hopefully you are almost ready to get to the taking our money point?

Hi,

Soon as we get new pictures and website updated....

So in February we should be able to release all the final cost and take orders.

As noted previously...the first couple batches the lead time will be dependent on barrel specifications/desires while we gain the market data on which spec'd barrels to have in stock.

Sincerely,

Theis

One could always build a form 1 suppressor. The material specs are all available. Gr5 Ti or 17-4SS could be machined well within any spec needed, I would think.I wonder if a suppressor for a 300 Norma would be adequate for a high pressure 308 (just examples)

Debating weather the first baffle will take too much of a beating because of the higher initial pressure

Or

Will the increased internal volume be adequate to absorb the increased energy

I would bet that one of these might be a good start, at least for the ASPIS series

WINDTALKER AMF .375, .408, .416 cal. Suppressor - Elite Iron

WINDTALKER AMF .375, .408, .416 cal. Suppressor - Elite Iron

Hi,

Yes, stay tuned for official announcement.

We are brainstorming names for that division right now, lol

Hoplite Arms Pantheon

Hoplite Arms Agoge

Training Division will be doing a video "owners manual" of the Aspis soon to go over all the features of the current T&E model as well as point out what has been refined already for the production model.

Sincerely,

Theis

sounds like i'll have a new match rifle ready for the season then

Hi,

Kopis is next on the schedule...we just want to make sure there are no issues with the Aspis before we have engineering finalize the production prints for Kopis.

Sincerely,

Theis

So assuming no issues with Aspis, shouldn’t take too long to get the Kopis into production since all you are really doing is lengthening the Aspis correct?Hi,

Kopis is next on the schedule...we just want to make sure there are no issues with the Aspis before we have engineering finalize the production prints for Kopis.

Sincerely,

Theis

other waySo assuming no issues with Aspis, shouldn’t take too long to get the Kopis into production since all you are really doing is lengthening the Aspis correct?

kopis is short/medium length

aspis is long

So assuming no issues with Aspis, shouldn’t take too long to get the Kopis into production since all you are really doing is lengthening the Aspis correct?

Hi,

The Apsis is actually the middle size design.

The Kopis is smaller BUT the only parts that are dimensionally different from the Aspis are the following:

Receiver Body

Firing Pin

Bolt Body

Center Section of chassis

All others are the same.

Sincerely,

Theis

Hi,

Chassis straight back from Birdsong....now it is time to "preheat" it before going into the destruction oven, lol

Sincerely,

Theis

Chassis straight back from Birdsong....now it is time to "preheat" it before going into the destruction oven, lol

Sincerely,

Theis

Hi,

Chassis check #1.

Chassis check #1 inspection.

Sincerely,

Theis

Chassis check #1.

Chassis check #1 inspection.

Sincerely,

Theis

Hi,

Chassis straight back from Birdsong....now it is time to "preheat" it before going into the destruction oven, lol

Sincerely,

Theis

That does look really nice now that it’s in color

Hi,

Chassis check #1.

Chassis check #1 inspection.

Sincerely,

Theis

Looks suspiciously like a famous “how to break in a rifle” video.

Hi,

Chassis check #1.

Chassis check #1 inspection.

Sincerely,

Theis

Blem sale?

Every torture test on YouTube drags them behind a truck. Going to be highly disappointed if you don’t follow suite. I mean how can you say you tested the system if you can didn’t drag it down a gravel road for 5 miles? I’ve ran into the situation where I needed to do that all the time and I need to know my rifle will survive

You should paint all your rifles red...you beat them like a red headed step child lol

Hi,

That's pretty funny but the reality of the situation is that IF the manufacturer is not willing to learn exactly where shit breaks then how can that manufacturer truly know what their product can and more importantly..cannot handle.

While we all understand numbers and can dissect alloy strengths down to pure numbers in which the properties of the alloys can be easily found in regards to what it can and cannot handle....

None of that matters if the connecting hardware sheers off from 2 mating pieces acting as scissors.

None of that matters if the mating surfaces are not designed with the correct connecting interfaces.

We can run the numbers and simulations on that data all day long but we get faster and more realistic thresholds from just slinging shit across the yard sometimes, lol.

Sincerely,

Theis

And how about shooting the chassis onto the moon?!

Hi,

Well, my friend Max does own his own space ships and launch pads.......

Sincerely,

Theis

Hi,

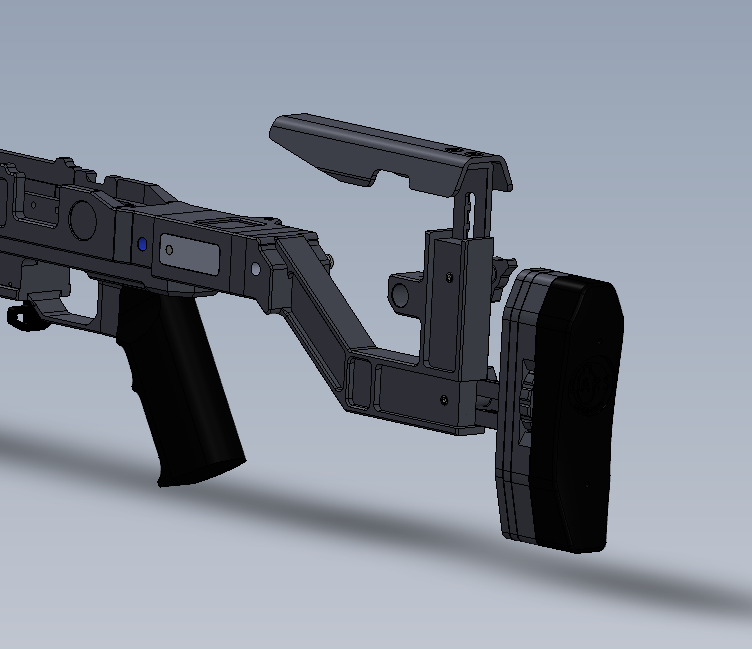

So just to show how fast things change for the better, lol...

From the fully completed chassis as shown in the above post videos to what will be the production (A few other tweeks coming, lol) model chassis...

We have "mirrored" the left and right side of the buttstock so the end user can determine what side(s) they want the LOP bracket, Cheek Piece bracket and their respective adjustment knobs to be on.

We have also removed the visible nut attaching the adjustment knobs and went with a hidden threaded shaft.

We have also cleaned the buttstock angle piece where it mates against the hinge and slops downward to ensure the stock folds/locks without having any issues of the bolt handle being in the way.

We also have about 2 pages of various programming, machining, radii, etc improvements.

Sincerely,

Theis

So just to show how fast things change for the better, lol...

From the fully completed chassis as shown in the above post videos to what will be the production (A few other tweeks coming, lol) model chassis...

We have "mirrored" the left and right side of the buttstock so the end user can determine what side(s) they want the LOP bracket, Cheek Piece bracket and their respective adjustment knobs to be on.

We have also removed the visible nut attaching the adjustment knobs and went with a hidden threaded shaft.

We have also cleaned the buttstock angle piece where it mates against the hinge and slops downward to ensure the stock folds/locks without having any issues of the bolt handle being in the way.

We also have about 2 pages of various programming, machining, radii, etc improvements.

Sincerely,

Theis

I can’t remember, what’s the minimum LOP?Hi,

So just to show how fast things change for the better, lol...

From the fully completed chassis as shown in the above post videos to what will be the production (A few other tweeks coming, lol) model chassis...

We have "mirrored" the left and right side of the buttstock so the end user can determine what side(s) they want the LOP bracket, Cheek Piece bracket and their respective adjustment knobs to be on.

We have also removed the visible nut attaching the adjustment knobs and went with a hidden threaded shaft.

We have also cleaned the buttstock angle piece where it mates against the hinge and slops downward to ensure the stock folds/locks without having any issues of the bolt handle being in the way.

We also have about 2 pages of various programming, machining, radii, etc improvements.

Sincerely,

Theis

View attachment 7531797

View attachment 7531799

Familydude

Spending my kids’ paltry inheritance on hobbies

Supporter

Full Member

Minuteman

Supporter

I came across this thread last week or so and have read through I think, the majority of the posts. My apologies if this question was previously asked and answered: Will the chassis be available separately and if so, what action(s) is it compatible with or, only as a complete rifle with most/all things proprietary?Hi,

So just to show how fast things change for the better, lol...

From the fully completed chassis as shown in the above post videos to what will be the production (A few other tweeks coming, lol) model chassis...

We have "mirrored" the left and right side of the buttstock so the end user can determine what side(s) they want the LOP bracket, Cheek Piece bracket and their respective adjustment knobs to be on.

We have also removed the visible nut attaching the adjustment knobs and went with a hidden threaded shaft.

We have also cleaned the buttstock angle piece where it mates against the hinge and slops downward to ensure the stock folds/locks without having any issues of the bolt handle being in the way.

We also have about 2 pages of various programming, machining, radii, etc improvements.

Sincerely,

Theis

View attachment 7531797

View attachment 7531799

Thanks.

Hi,I can’t remember, what’s the minimum LOP?

Here are few measurements on that.

Closed:

Open

3D Model

Last edited:

I came across this thread last week or so and have read through I think, the majority of the posts. My apologies if this question was previously asked and answered: Will the chassis be available separately and if so, what action(s) is it compatible with or, only as a complete rifle with most/all things proprietary?

Thanks.

Hi,

As previously mentioned a few times; at this moment Hoplite Arms is not getting into the components sector of the industry.

Not to say that we won't later down the road but right now we will not be diving off into that headache.

There are lots of companies already purely focused on that sector of the industry; to the point the industry is lagging in advancements.

Also, to continue the transparency and upfront level discussions.....

That chassis as manufactured in 7075 Aluminum cannot compete in price margins against all the 6061 Aluminum chassis' on the market.

As a standalone chassis we would have to lower the grade of our alloys or attempt to charge a price higher than all the others.

Sincerely,

Theis

Familydude

Spending my kids’ paltry inheritance on hobbies

Supporter

Full Member

Minuteman

Supporter

Got it. Thanks for your patience.Hi,

As previously mentioned a few times; at this moment Hoplite Arms is not getting into the components sector of the industry.

Not to say that we won't later down the road but right now we will not be diving off into that headache.

There are lots of companies already purely focused on that sector of the industry; to the point the industry is lagging in advancements.

Also, to continue the transparency and upfront level discussions.....

That chassis as manufactured in 7075 Aluminum cannot compete in price margins against all the 6061 Aluminum chassis' on the market.

As a standalone chassis we would have to lower the grade of our alloys or attempt to charge a price higher than all the others.

Sincerely,

Theis

Got it. Thanks for your patience.

Hi,

No thanks needed!!

We are the company and for a company to be viable it requires customers AND a continual growth of interest in order to convert interest to customers.

Questions are the first line of communication a lot of the time so this business and anyone whom works for it will field questions no matter what, over and over and over if that is what that potential customer requires as part of their individual customer journey.

We will not outsell some of the manufacturers in our marketspace but we will produce a superior product and we will out service them all.

Sincerely,

Theis

Last edited:

Familydude

Spending my kids’ paltry inheritance on hobbies

Supporter

Full Member

Minuteman

Supporter

See you at PalaHi,

No thanks needed!!

We are the company and for a company to be viable it requires customers AND a continual growth of interest in order to convert interest to customers.

Questions are the first line of communication a lot of the time so this business and anyone whom works for it will field questions no matter what, over and over and over if that is what that potential customer requires as part of their individual customer journey.

We will not outsell some of the manufacturers in our marketspace but we will produce a superior product and we will out service them all.

Sincerely,

Theis

Got it. Thanks for your patience.

Just buy the complete Hoplite rifle, you'll get a top notch action and an excellent barrel made from the new Bartlein steel.

The up side being you can have fun (so long as you can find strong brass), doing reloading to higher pressures than a standard rifle would allow.

Just buy the complete Hoplite rifle, you'll get a top notch action and an excellent barrel made from the new Bartlein steel.

The up side being you can have fun (so long as you can find strong brass), doing reloading to higher pressures than a standard rifle would allow.

Hi,

We are taking steps to remove that supply issue from other companies and put some directly spec'd brass rods into the swiss screw machine and see how it goes, lol.

Sincerely,

Theis

Familydude

Spending my kids’ paltry inheritance on hobbies

Supporter

Full Member

Minuteman

Supporter

Believe me, I’d love to. Been salivating over it since I discovered this thread. Running out of things to sell! I’ll get it figured out.Just buy the complete Hoplite rifle, you'll get a top notch action and an excellent barrel made from the new Bartlein steel.

The up side being you can have fun (so long as you can find strong brass), doing reloading to higher pressures than a standard rifle would allow.

Just started shipping some barrels for Theis!

I know its early in the game; but high pressure rounds have a tendency of gaining my attention, and watching this weapon system develop has been amazing.Hi,

@gnochi

What size runway are you needing lol?

Luckily for our International .gov clients we are just about 2 hours from the Stennis Airport that most of them fly into the USA at anyways due to the amount of USA .gov agencies, .mil entities and various big MIC offices.

@Frank Green

AWESOME!!!!!

Sincerely,

Theis

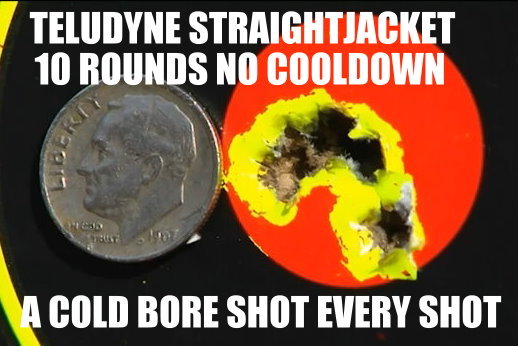

I tagged you both due to my question.

@Frank Green do you remember the StraightJacket system?

@THEIS is this a viable barrel upgrade for the end user? StraightJacket finished OD is 1.25" straight taper.

God damn it, this shit is going to be sick.

So are you starting with just the 1 or going to jump right in with one of everything HA!

I'm anxiously waiting for Theis to get to the "shut up and take my money" stage

Especially if he can also sell you some brass...

Hi Theis,

Do you have any updates on where you guys are at on the Phalanx action or the future for it?

Thanks

Hi,

The Phalanx is number 3 in line.

The Aspis will go into production around first of February.

The Kopis will follow soon after that since there are only about 5 pieces that are dimensionally shorter than the Aspis components.

Then we will start FEA and testing of alloys for the Phalanx.

Sincerely,

Theis

Hi,I know its early in the game; but high pressure rounds have a tendency of gaining my attention, and watching this weapon system develop has been amazing.

I tagged you both due to my question.

@Frank Green do you remember the StraightJacket system?

@THEIS is this a viable barrel upgrade for the end user? StraightJacket finished OD is 1.25" straight taper.

IMO all those aftermarket barrel life increasing methods are a waste. There is just no way possible to any external "heat sinks" to wick away heat from the throat fast enough to delay the onset of firecracking...It is just physically impossible. External barrel temperature doesn't mean jack shit IMO because barrels burn out from the throat forward....not external inwards lol.

That is why we have chosen to go with only the Bartlein ModBB alloy......the alloy composition is literally where the rubber meets the road and the only thing that will increase barrel life if you asking my opinion.

Sincerely,

Theis

What is the weight of the current chassis with the nv bridge?

Hi,

Been a hectic day getting everything ready for this weekend. Please give me till tomorrow and I will grab that weight while I eat lunch.

Sincerely,

Theis

Just happened to be listening to podcast with Precision Rifle Media that was in like September I think. So much for 2 monthsHi,

The Phalanx is number 3 in line.

The Aspis will go into production around first of February.

Sincerely,

Theis

Thank you for taking the time to at least respond, I know you are busy. Ill add a link or 2, for when you have time. It might help clarify what the StraightJacket is intended to do. No one gives a fuck about the outside temp, don't touch it. Throat erosion, and cold bore repeatability, are what I'm talking about In regards to the system.Hi,

The Phalanx is number 3 in line.

The Aspis will go into production around first of February.

The Kopis will follow soon after that since there are only about 5 pieces that are dimensionally shorter than the Aspis components.

Then we will start FEA and testing of alloys for the Phalanx.

Sincerely,

Theis

Hi,

IMO all those aftermarket barrel life increasing methods are a waste. There is just no way possible to any external "heat sinks" to wick away heat from the throat fast enough to delay the onset of firecracking...It is just physically impossible. External barrel temperature doesn't mean jack shit IMO because barrels burn out from the throat forward....not external inwards lol.

That is why we have chosen to go with only the Bartlein ModBB alloy......the alloy composition is literally where the rubber meets the road and the only thing that will increase barrel life if you asking my opinion.

Sincerely,

Theis

Hi,

Been a hectic day getting everything ready for this weekend. Please give me till tomorrow and I will grab that weight while I eat lunch.

Sincerely,

Theis

Teludyne StraightJacket Proof from H.P. White

Finally nobody has to believe GunsAmerica that the Teludyne StraightJacket is nothing short of a miracle for rifle accuracy over sustained fire. If you read our original article, Ultimate Accuracy Makeover, but didn't send your gun to Teludyne, you may want to beat the crowds now because they...

Descent Into Madness: Intro to Teludyne Tech and the “Straight Jacket” - The New Rifleman

Over the last few years, the quality in the A15 barrel market has improved substantially... even basic, free floated barrels have been shown capable of 1 MOA or better with quality ammunition. Not only has the quality improved, but so has the pricing. In spite of any advancements the market has...

www.thenewrifleman.com

I think the system is a winner. I buy proof through testing and science. No different from any number of members interested in your rifle, without holding or test firing it. I, personally, would be interested in how it works in conjunction with your high pressure cartridge system. For science, I guess. Of course, In the end, I'd like to have one regardless

Last edited:

Hi,Just happened to be listening to podcast with Precision Rifle Media that was in like September I think. So much for 2 months

Yea lots of things have changed since then.

And guess how many heat treatment companies in the USA have ever dealt with our Aermet 100 alloy....

Hint...don't count higher than your 2 thumbs.

Guess how much money was spent on static and dynamic FEA in order to improve the system in the last 6 months....

We could buy that thermal scope I sent you the text about, haha.

Then 1 of them messed up the first batch.

Then the largest independent owned coating company in the USA had stuff for 9ver 30 days only to send it back done wrong..what part they did do and didn't do anything to all the other parts lol.

I could go on and on lol but bottom line is even though our schedules have indeed been pushed well beyond what we wanted...we took that time to improve the system and done so all without taking a single penny from a customer.

Sincerely,

Theis

Just giving you a little ribbing, wasn’t meant to be derogatory. A lot has changed since then. We all see what and why delays have happened and it all boils down to your core business model which is don’t release a product that is not 100%Hi,

Yea lots of things have changed since then.

And guess how many heat treatment companies in the USA have ever dealt with our Aermet 100 alloy....

Hint...don't count higher than your 2 thumbs.

Guess how much money was spent on static and dynamic FEA in order to improve the system in the last 6 months....

We could buy that thermal scope I sent you the text about, haha.

Then 1 of them messed up the first batch.

Then the largest independent owned coating company in the USA had stuff for 9ver 30 days only to send it back done wrong..what part they did do and didn't do anything to all the other parts lol.

I could go on and on lol but bottom line is even though our schedules have indeed been pushed well beyond what we wanted...we took that time to improve the system and done so all without taking a single penny from a customer.

Sincerely,

Theis

what you have created is going to be an incredible machine once it’s ready to go.

Thank you for taking the time to at least respond, I know you are busy. Ill add a link or 2, for when you have time. It might help clarify what the StraightJacket is intended to do. No one gives a fuck about the outside temp, don't touch it. Throat erosion, and cold bore repeatability, are what I'm talking about In regards to the system.

Teludyne StraightJacket Proof from H.P. White

Finally nobody has to believe GunsAmerica that the Teludyne StraightJacket is nothing short of a miracle for rifle accuracy over sustained fire. If you read our original article, Ultimate Accuracy Makeover, but didn't send your gun to Teludyne, you may want to beat the crowds now because they...www.gunsamerica.com

Descent Into Madness: Intro to Teludyne Tech and the “Straight Jacket” - The New Rifleman

Over the last few years, the quality in the A15 barrel market has improved substantially... even basic, free floated barrels have been shown capable of 1 MOA or better with quality ammunition. Not only has the quality improved, but so has the pricing. In spite of any advancements the market has...www.thenewrifleman.com

I think the system is a winner. I buy proof through testing and science. No different from any number of members interested in your rifle, without holding or test firing it. I, personally, would be interested in how it works in conjunction with your high pressure cartridge system. For science, I guess. Of course, In the end, I'd like to have one regardless

Hi,

I remember Teludyne system when it first came out and my only non-academic concern of the system is that being it has been around for over 10 years and we still do not see really anyone using them.....that is a big flag of concern for me.

Now onto an academic concern...there is just not any way whatsoever that throat burnout can be prevented from "removing heat" via an external source...it just cannot wick heat away as fast as the ignition temperature torches the throat.

I offered to send one of the structured barrels being marketed in ELR world today to NTS testing facility for real scientific testing and documentations......Still waiting on reply to that one, lolol

Sincerely,

Theis

Just giving you a little ribbing, wasn’t meant to be derogatory.

Hi,

Yea I figured that much but my reply was more inline for anyone else reading through and wanted to get in on the "delays" conversation, lol.

Sincerely,

Theis

Although not my preferred system; the Dracos is one of the places Teludyne's work is being used.Hi,

I remember Teludyne system when it first came out and my only non-academic concern of the system is that being it has been around for over 10 years and we still do not see really anyone using them.....that is a big flag of concern for me.

Now onto an academic concern...there is just not any way whatsoever that throat burnout can be prevented from "removing heat" via an external source...it just cannot wick heat away as fast as the ignition temperature torches the throat.

I offered to send one of the structured barrels being marketed in ELR world today to NTS testing facility for real scientific testing and documentations......Still waiting on reply to that one, lolol

Sincerely,

Theis

Hi,

Yea I figured that much but my reply was more inline for anyone else reading through and wanted to get in on the "delays" conversation, lol.

Sincerely,

Theis

You've made your stand at throat erosion. Fair enough. What is NTS, and why are you laughing at not receiving a reply from them? Is it your barrel you're having tested? What are you wanting them to test? Forgive my ignorance, or lack of Google-fu. Whichever it may be. My other concern; from longevity, was cold bore repeatability. Thats a real thing. But I suppose the general group response to that will be, "record your shift".

Had a feeling I'd be pissing into the wind here. Worth a shot though. Thanks for your time. Enjoy seeing the updates

Although not my preferred system; the Dracos is one of the places Teludyne's work is being used.

You've made your stand at throat erosion. Fair enough. What is NTS, and why are you laughing at not receiving a reply from them? Is it your barrel you're having tested? What are you wanting them to test? Forgive my ignorance, or lack of Google-fu. Whichever it may be. My other concern; from longevity, was cold bore repeatability. Thats a real thing. But I suppose the general group response to that will be, "record your shift".

Had a feeling I'd be pissing into the wind here. Worth a shot though. Thanks for your time. Enjoy seeing the updates

NTS | Testing, Inspection & Certification Services

NTS is the leading independent provider of environmental simulation testing, inspection, and certification services.

What is NTS, and why are you laughing at not receiving a reply from them?

NTS is a really well regarded testing company for hardcore engineering work. You won’t really have heard of them unless you’re in the industry, but they’re basically the gold standard. They run the tests well, keep the equipment maintained, and have good engineering support for developing the tests you need to run.

Edit: I see that their tag line is “the leading supplier” and I would say that’s accurate. There are some niche suppliers that have more capability in a couple areas, but only just.

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 214