Correct. But you knew what I was saying. The jam nut sets the barrel in place and keeps it there after headspace is adjusted via screwing the barrel in/out until correct with proper headspace gauges.Yes, it's the barrel nut.

So that some other's who read this may not be confused with your question, this barrel nut does NOT "set head space". It will lock in the head space after you set it by how far you screw the barrel in having measured the distance with go & no-go gauges.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I shoot with several friends, initially was a 1000 yard target, then milk gallon then 1500 yards except we screwed up and it is actually at 1600; then some smart elbow suggested a mile (less than 200 yards more). My 6.5 CR was ok up to this point.

First time out with my RPR 338.

Std RPR, Vortex PST II FFP 5-25 MOA, Atlas CAL Bipod. Reloads

Loaded 50 rounds, 285 Gr Hornady Match HPBT. Powder charges: 88.0, 88.5, 89.0, 89.5, 90.0 (use at you own discretion) Federal magnum primers, Norma brass

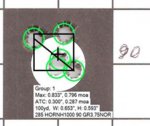

This group was at 100 yards, with a MagnetoSpeed attached. 90Gr, Average 2810 fps. SD: of 35 fps

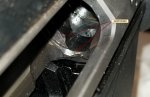

Then I noticed an odd deformation on the fired cased, it is not very deep, however it can be felt with a fingernail

Any ideas what could be causing this? I did not experience any difficulties opening or ejecting the case. Primer was not flattened.

I will be posting the same question on the reloading forum

Recoil with this 17 lb rifle is manageable, I fired 50 rounds over several hours and was not bruised or develop a flinch.

I like this beast. Next trip will be to the desert.

First time out with my RPR 338.

Std RPR, Vortex PST II FFP 5-25 MOA, Atlas CAL Bipod. Reloads

Loaded 50 rounds, 285 Gr Hornady Match HPBT. Powder charges: 88.0, 88.5, 89.0, 89.5, 90.0 (use at you own discretion) Federal magnum primers, Norma brass

This group was at 100 yards, with a MagnetoSpeed attached. 90Gr, Average 2810 fps. SD: of 35 fps

Then I noticed an odd deformation on the fired cased, it is not very deep, however it can be felt with a fingernail

Any ideas what could be causing this? I did not experience any difficulties opening or ejecting the case. Primer was not flattened.

I will be posting the same question on the reloading forum

Recoil with this 17 lb rifle is manageable, I fired 50 rounds over several hours and was not bruised or develop a flinch.

I like this beast. Next trip will be to the desert.

^ Maybe hitting the edge of the ejection port on the way out or hitting a feed ramp on the way in? Maybe a mag issue? It is a strange marking. You could slo mo it with your phone

I’m guessing either there’s a extractor issue or your mag spring is too strong. Try loading the magazine to max capacity, then instead of chambering the rounds, just slide them out with your finger and look for the markings

I’m guessing either there’s a extractor issue or your mag spring is too strong. Try loading the magazine to max capacity, then instead of chambering the rounds, just slide them out with your finger and look for the markings

Last edited:

At Sam's Club, I bought a nice hard gun case at a great price for my new RPR. It works well for storage and would be necessary to fly with it. Still, it's pretty heavy in one hand over distance. While it rolls, it doesn't seem like the wheels would last long schlepping the quarter mile each way at the nearest outdoor gun range. I could sling this 20+ pound beast over my back and carry in the rest in a range bag. Was considering a soft case. Curious what you guys use on range day?

Loaded 50 rounds, 285 Gr Hornady Match HPBT. Powder charges: 88.0, 88.5, 89.0, 89.5, 90.0 (use at you own discretion) Federal magnum primers, Norma brass

------

Then I noticed an odd deformation on the fired cased, it is not very deep, however it can be felt with a fingernail

View attachment 7052576

Any ideas what could be causing this? I did not experience any difficulties opening or ejecting the case. Primer was not flattened.

I will be posting the same question on the reloading forum

Retumbo?

The fine linear scratches are mag feed lips for sure. I had to sand mine down.

I'm not sure about that gouge though. Catching on the feed ramp?

^ I agree. Hitting the ejection port usually causes the casings to be dented, not scratched. And if they’re hitting that hard you’re usually talking a semi auto problem.

It almost looks like it’s either scratching against the mag lip, or the bottom rim of the casing is scratching the casing below it as it’s being picked up and pushed forward by the bolt. If it’s a problem with a feed ramp, then it seems to me that something would be misaligned.

It almost looks like it’s either scratching against the mag lip, or the bottom rim of the casing is scratching the casing below it as it’s being picked up and pushed forward by the bolt. If it’s a problem with a feed ramp, then it seems to me that something would be misaligned.

^ Yeah could be something on the backward stroke of the bolt cycle. Id slo mo it and see if there’s anything obvious on video

^ That was one of my initial thoughts. The mag spring tension is too strong when loaded to capacity, pushing the rounds up as high as possible. Too high. You can try to modify the spring. A lot of people just buy a new mag. You could also raise the issue with Ruger of course

Thank you for all the comments. Howland I reloaded using 90 Gr of H1000

Today's research:

1. I loaded (5) dummy loads using virgin Peterson brass ((beautiful brass)

2. Cycled them thru the action at different speeds, no issues (dragging sensation, hangups) repeated 3-4 times. no issues (other than my wife scolding me for doing this at the dinner table LOL). Some longitudinal scratches from the magazine. no gouges. Bullet tips show some scratches indicative of a rough/sharp feed ramp

Notes:

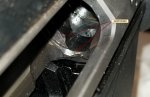

Sharp edges on the feed ramp, ejection port and barrel extension. Ejection port and feed ramp also show brass smear marks

Following Ruger's instructions the lower (receiver?) was removed

Rework:

Using a Swiss round file I proceeded to break all accessible sharp edges. Sorry forgot to photograph the feed ramp and I am too lazy to retrieve the rifle from the safe. Metal removal was minimum.

Conclusion:

Close inspection of the initial cases showed different degrees of "gouging" from severe (shown) to minimum to none. Perhaps the culprit "burr" was removed during cycling/firing.

Unable to replicate root cause one solution was to address all suspect contributors: remove/limit sharp edges that contact the case.

Will find out more next range trip. Thanks

ACK

Today's research:

1. I loaded (5) dummy loads using virgin Peterson brass ((beautiful brass)

2. Cycled them thru the action at different speeds, no issues (dragging sensation, hangups) repeated 3-4 times. no issues (other than my wife scolding me for doing this at the dinner table LOL). Some longitudinal scratches from the magazine. no gouges. Bullet tips show some scratches indicative of a rough/sharp feed ramp

Notes:

Sharp edges on the feed ramp, ejection port and barrel extension. Ejection port and feed ramp also show brass smear marks

Following Ruger's instructions the lower (receiver?) was removed

Rework:

Using a Swiss round file I proceeded to break all accessible sharp edges. Sorry forgot to photograph the feed ramp and I am too lazy to retrieve the rifle from the safe. Metal removal was minimum.

Conclusion:

Close inspection of the initial cases showed different degrees of "gouging" from severe (shown) to minimum to none. Perhaps the culprit "burr" was removed during cycling/firing.

Unable to replicate root cause one solution was to address all suspect contributors: remove/limit sharp edges that contact the case.

Will find out more next range trip. Thanks

ACK

Attachments

Last edited:

Xandrosi

1/4 mile stroll on a rifle case? Not advisable as the wheels (at least on Storm) are relatively small. My recommendation would be to carry the rifle using an Eberlestock Rifle Backpack. Or get a folding handtruck. I use something similar to this folding hand truck when the terrain is paved.

Folding hand truck

1/4 mile stroll on a rifle case? Not advisable as the wheels (at least on Storm) are relatively small. My recommendation would be to carry the rifle using an Eberlestock Rifle Backpack. Or get a folding handtruck. I use something similar to this folding hand truck when the terrain is paved.

Folding hand truck

Thanks Ack. That folding hand truck seems perfect and relatively inexpensive. At some point, I'll probably invest in an Eberlestock or something like it. Putting it off for now.Xandrosi

1/4 mile stroll on a rifle case? Not advisable as the wheels (at least on Storm) are relatively small. My recommendation would be to carry the rifle using an Eberlestock Rifle Backpack. Or get a folding handtruck. I use something similar to this folding hand truck when the terrain is paved.

Folding hand truck

Thank you for all the comments. Howland I reloaded using 90 Gr of H1000

Today's research:

1. I loaded (5) dummy loads using virgin Peterson brass ((beautiful brass)

2. Cycled them thru the action at different speeds, no issues (dragging sensation, hangups) repeated 3-4 times. no issues (other than my wife scolding me for doing this at the dinner table LOL). Some and longitudinal scratches from the magazine. no gouges. Bullet tips show some scratches indicative of a rough/sharp feed ramp

View attachment 7053056

Notes:

Sharp edges on the feed ramp, ejection port and barrel extension. Ejection port and feed ramp also show brass smear marks

View attachment 7053057

Following Ruger's instructions the lower (receiver?) was removed

Rework:

Using a Swiss round file I proceeded to break all accessible sharp edges. Sorry forgot to photograph the feed ramp and I am too lazy to retrieve the rifle from the safe. Metal removal was minimum.

View attachment 7053059

Conclusion:

Close inspection of the initial cases showed different degrees of "gouging" from severe (shown) to minimum to none. Perhaps the culprit "burr" was removed during cycling/firing.

Unable to replicate root cause one solution was to address all suspect contributors: remove/limit sharp edges that contact the case.

Will find out more next range trip. Thanks

ACK

Makes sense your case wasn’t the mag spring as all your casings were scratched. The scratches should go away towards the second half of the mag as spring tension is being relieved. Glad you got it figured out and nice work!

Xandrosi, folding hand trucks are a multipurpose tool for the sportsman. I used to dive with my niece, (she outgrew me) the walk was a couple of hundred yards. The manly divers would suit up and walk in their wetsuit carrying all their gear. I would just load my hand truck and wheel my gear across.

Thanks again. My RPR has been dormant for awhile. Just going through stuff I had in a box. I’m using a PVA nut setup with a Seekins rail. Thinking about getting the Catalyst Arms Fast Track rail and per their instructions retains the factory jam nut.

021411, did you get everything figured out about the RPR barrel nut and handguard nut? If you need send a note to us at [email protected] .

So I had a rather unpleasant experience getting the factory barrel off my RPR. I took it to a gunsmith because I figured it would be the safer route over trying to do it myself. We started by taking the handguard off and putting it in the barrel vise. The handguard nut came off with no issues. Then he didn't have a AR wrench, which was an omen of things to come. I went and picked up the wrench. Came back and we proceeded to try to get the barrel off. Watched a quick youtube video which showed the nut unscrewing counter clockwise if you are in the shooters position. Great. He started turning the nut. It moved a little bit, but wasn't coming loose. Next came the hammer. He pounded on the wrench while cursing about the factory making things way too tight. It was moving but still not coming loose. I should have known that something was wrong when it was turning, but not breaking free, but nevertheless I trusted the person with all the experience. He actually is an excellent gunsmith, but doesn't deal with RPRs. Then I started watching the entire video and others and saw that the lower needed to be removed. We removed the two screws required and the lower would not come off. I thought that maybe the safety needed to be off or something. I couldn't turn the safety. Then we thought well, maybe the bolt needs to be in it. Put in the bolt and it closed but, something was pressing against it that it wasn't moving freely and I could feel it grinding when I removed it. The lower still wouldn't come off and I couldn't change the safety. The lower was probably rotated 80 degrees (~1/4 turn) from where it started originally. Then he said let me try to back the nut off and see if it releases anything, it's probably binding it up. He pounded on the nut in the opposite direction and it spun freely off. "Oh, it's a jam nut".

We inspected everything and there doesn't appear to be any damage, besides a couple of the ears on the barrel nut are bent off. He assured me that it will be fine and I can't see any damage on anything. Part of me can't help but think that something has to be screwed up though. I called Ruger and they said that they can't tell anything for sure over the phone and mentioned that the barrel nut is torqued to 150 ft*lb. Add another quarter turn onto that baby and it had to be screaming tight.

What would you do? (he is kind of a friend) Do you think anything is screwed up?

I just spend $575 on a Kreiger barrel and it doesn't give me a warm fuzzy screwing it onto something that just got beat to death with a hammer. I worry that there could be something unseen wrong that would affect the accuracy which I just paid a premium to maximize. I don't really want to find out that something is wrong after I shoot 200 rounds through it and can't get it to tune to excellence.

It really annoys me that I didn't prepare better for this going into things, but I thought that's what I was paying an expert to do.

We inspected everything and there doesn't appear to be any damage, besides a couple of the ears on the barrel nut are bent off. He assured me that it will be fine and I can't see any damage on anything. Part of me can't help but think that something has to be screwed up though. I called Ruger and they said that they can't tell anything for sure over the phone and mentioned that the barrel nut is torqued to 150 ft*lb. Add another quarter turn onto that baby and it had to be screaming tight.

What would you do? (he is kind of a friend) Do you think anything is screwed up?

I just spend $575 on a Kreiger barrel and it doesn't give me a warm fuzzy screwing it onto something that just got beat to death with a hammer. I worry that there could be something unseen wrong that would affect the accuracy which I just paid a premium to maximize. I don't really want to find out that something is wrong after I shoot 200 rounds through it and can't get it to tune to excellence.

It really annoys me that I didn't prepare better for this going into things, but I thought that's what I was paying an expert to do.

You should be fine with the new barrel and a new barrel nut. I used one from PVA...https://patriotvalleyarms.com/cart.php?suggest=090adf77-ae62-4def-be25-7b0a2131f851So I had a rather unpleasant experience getting the factory barrel off my RPR. I took it to a gunsmith because I figured it would be the safer route over trying to do it myself. We started by taking the handguard off and putting it in the barrel vise. The handguard nut came off with no issues. Then he didn't have a AR wrench, which was an omen of things to come. I went and picked up the wrench. Came back and we proceeded to try to get the barrel off. Watched a quick youtube video which showed the nut unscrewing counter clockwise if you are in the shooters position. Great. He started turning the nut. It moved a little bit, but wasn't coming loose. Next came the hammer. He pounded on the wrench while cursing about the factory making things way too tight. It was moving but still not coming loose. I should have known that something was wrong when it was turning, but not breaking free, but nevertheless I trusted the person with all the experience. He actually is an excellent gunsmith, but doesn't deal with RPRs. Then I started watching the entire video and others and saw that the lower needed to be removed. We removed the two screws required and the lower would not come off. I thought that maybe the safety needed to be off or something. I couldn't turn the safety. Then we thought well, maybe the bolt needs to be in it. Put in the bolt and it closed but, something was pressing against it that it wasn't moving freely and I could feel it grinding when I removed it. The lower still wouldn't come off and I couldn't change the safety. The lower was probably rotated 80 degrees (~1/4 turn) from where it started originally. Then he said let me try to back the nut off and see if it releases anything, it's probably binding it up. He pounded on the nut in the opposite direction and it spun freely off. "Oh, it's a jam nut".

We inspected everything and there doesn't appear to be any damage, besides a couple of the ears on the barrel nut are bent off. He assured me that it will be fine and I can't see any damage on anything. Part of me can't help but think that something has to be screwed up though. I called Ruger and they said that they can't tell anything for sure over the phone and mentioned that the barrel nut is torqued to 150 ft*lb. Add another quarter turn onto that baby and it had to be screaming tight.

What would you do? (he is kind of a friend) Do you think anything is screwed up?

I just spend $575 on a Kreiger barrel and it doesn't give me a warm fuzzy screwing it onto something that just got beat to death with a hammer. I worry that there could be something unseen wrong that would affect the accuracy which I just paid a premium to maximize. I don't really want to find out

I shoot 200 rounds through it and can't get it to tune to excellence.

It really annoys me that I didn't prepare better for this going into things, but I thought that's what I was paying an expert to do.

Last edited:

Just know that the included wrench wasn’t made for multi use. Just stick to the specified torque values by PVA and you should be fine.You should be fine with the new barrel and a new barrel nut. I used one from PVA...https://patriotvalleyarms.com/cart.php?suggest=090adf77-ae62-4def-be25-7b0a2131f851

True, that’s one flimsy flat wrench. They make that way to insure your don’t torque the nut more than 35 ft lbs...Just know that the included wrench wasn’t made for multi use. Just stick to the specified torque values by PVA and you should be fine.

You should be fine with the new barrel and a new barrel nut. I used one from PVA...https://patriotvalleyarms.com/cart.php?suggest=090adf77-ae62-4def-be25-7b0a2131f851

Why was the bolt grinding when I removed it and hard to close? Safety wouldn't work. Something had to give. Makes me nervous.

The Krieger is in and everything is buttoned back up?Why was the bolt grinding when I removed it and hard to close? Safety wouldn't work. Something had to give. Makes me nervous.

Stock trigger?

Pull the trigger and clean the action & bolt well including the threads then screw on new barrel. Put it all back together and check functionality. You should be good to go and don’t forget to use go/no go gauges...Why was the bolt grinding when I removed it and hard to close? Safety wouldn't work. Something had to give. Makes me nervous.

The Krieger is in and everything is buttoned back up?

Stock trigger?

Yes, it all went back together seemingly fine. Still stock trigger.

I know the stock trigger has a spring thing you had to lock or unlock.

Stand by let me find.

We definitely missed that step.

Why was the bolt grinding when I removed it and hard to close? Safety wouldn't work. Something had to give. Makes me nervous.

With all that pounding with the lower still in place, it sounds like something(s) got shaken up/moved out of place that's now causing this. I'd check all the things internally to be sure they all in the right place (like the safety and it's spring).

Kind of curious? The lower needs to be removed to remove the barrel nut lock item #86 on the parts diagram. This also is where the clevis mount for the lower is. If you tried to break the barrel nut with all of this in place with the lower you would have a FUBAR condition?With all that pounding with the lower still in place, it sounds like something(s) got shaken up/moved out of place that's now causing this. I'd check all the things internally to be sure they all in the right place (like the safety and it's spring).

Correct me if I'm wrong?

I have done a few of these.

I own both and they are probably equal in terms of quality and performance. The Hawk Hill I own happens to be on my RPR and shoots amazingly well. Just shot this group with it last weekend. Five shots at 100 yds from bipod and rear squeeze bag.I see someone metioned a page or so back about getting a hawk hill. What do you guys think about them vs the Kriegers? I was about to order a Krieger but wanted a comparison first

Attachments

got one on the way now!I own both and they are probably equal in terms of quality and performance. The Hawk Hill I own happens to be on my RPR and shoots amazingly well. Just shot this group with it last weekend. Five shots at 100 yds from bipod and rear squeeze bag.

No one can gripe about a group like that.I own both and they are probably equal in terms of quality and performance. The Hawk Hill I own happens to be on my RPR and shoots amazingly well. Just shot this group with it last weekend. Five shots at 100 yds from bipod and rear squeeze bag.

I find it thoroughly disturbing that your gunsmith is using Youtube as a reliable source for information.

I find it thoroughly disturbing that your gunsmith is using Youtube as a reliable source for information.

I agree 110%. I would not use that gunsmith again.

Good luck with the reloading. Ammo will be less expensive & can be tuned for your rifle with usually somewhat better accuracy.

My feelings on this is pretty straightforward! Any Smith that doesn't have an AR Wrench is a clear and present danger and you should move on... I'm glad you're all sorted out...

I own both and they are probably equal in terms of quality and performance. The Hawk Hill I own happens to be on my RPR and shoots amazingly well. Just shot this group with it last weekend. Five shots at 100 yds from bipod and rear squeeze bag.

My Hawkhill groups well!

Anyone use a hand press for reloading? Just curious. I got a Lee hand press a couple weeks ago and it’s great. I reload while sitting on the couch drinking a beer and watching tv

Yup. I have an arbor press and some Wilson hand dies for when I feel like a couch potato.

New bipod is awesome on the RPR

Atlas gen 2 cal

I came from a Harris, and even though they do the same thing, the atlas feels like a upgrade. I'm. Loving it

A hand press is what I used when I reloaded 22/250. I had no complaints with it. You can do the same things as a turret style, just not the volume/speed, with all the separate pieces

Finally had a chance to shoot my RPR .300 win mag. Tried several 5 shot groups with Winchester brass, 225gr ELDM bullets, H1000 powder ranging from 75.9-77.1gr, GM215M primers, .025 off lands.

Vortex viper gen2 5x25 scope

Bag in rear Harris bipod up front

Only managed mediocre accuracy. 1.25- 1.5 MOA @150 yards. Had a couple groups where 4 of 5 shots were in the .5-.6 MOA range. The flier was typically off in windage.

The best load was 76.8gr. 2888fps average, 13ES, 5SD as measured with a Prochrono at 15' from muzzle. It managed a .55MOA vertical spread and 4 of 5 where within a .6MOA. windage spread but one round brought the windage out to nearly 1.5. Sucks. I may have to play with seating depths to see if that helps with windage dispersion. The ELD M bullet has a secant ogive so it could be sensitve to seating depth like other VLD-style bullets. BTW, Cross wind was variable but <= 5MPH so I don't think it was wind induced.

Hope I can figure it out.

Btw, the recoil was very modest. The brake works well and the rifle is getting close to 20# so that helps too.

Vortex viper gen2 5x25 scope

Bag in rear Harris bipod up front

Only managed mediocre accuracy. 1.25- 1.5 MOA @150 yards. Had a couple groups where 4 of 5 shots were in the .5-.6 MOA range. The flier was typically off in windage.

The best load was 76.8gr. 2888fps average, 13ES, 5SD as measured with a Prochrono at 15' from muzzle. It managed a .55MOA vertical spread and 4 of 5 where within a .6MOA. windage spread but one round brought the windage out to nearly 1.5. Sucks. I may have to play with seating depths to see if that helps with windage dispersion. The ELD M bullet has a secant ogive so it could be sensitve to seating depth like other VLD-style bullets. BTW, Cross wind was variable but <= 5MPH so I don't think it was wind induced.

Hope I can figure it out.

Btw, the recoil was very modest. The brake works well and the rifle is getting close to 20# so that helps too.

Last edited:

Definitely ditch the pmags that came with the rifle. I went to a magpul Asics? It's the 5 rounder that doesn't have the bolt catch,and allows you to seat bullets farther out.

It made a huge difference in the action/feeding. Much smoother now.

Going to try a AI mag soon and see if it's even better.

I need to do this as well. Putting in a mag and getting it out just sucks. 1st round chamber feels like it binds a bit as well. I need to get some metal mag I assume.

Ended up purchasing a Catalyst Arms Fast Track rail for the RPR. Looks very promising with the full length arca type rail. It feels pretty solid. Once my barrel vise comes in I’m gonna do some tweaking on the barrel and then will get the Fast Track installed.

Attachments

Yes it will make a massive difference. Even the aics style magpul plastic mag is a big difference from an AR style pmagI need to do this as well. Putting in a mag and getting it out just sucks. 1st round chamber feels like it binds a bit as well. I need to get some metal mag I assume.

Similar threads

- Replies

- 0

- Views

- 202

- Replies

- 13

- Views

- 679

- Replies

- 3

- Views

- 420

- Replies

- 17

- Views

- 1K