Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sleuthing the Federal Gold Medal match load... Mk 316 Mod 0?

- Thread starter Dan Newberry

- Start date

-

- Tags

- fgmm

Shot some more of this powder in the MK319 brass as well as others:

It looks like the MK316 brass is just another variant of FGMM commercial brass. It weighs 176grs and has the same water capacity and neck thickness. It gives the same velocity, ES and SD.

It is NOT the same as LC LR. Look at the velocity difference: 20 FPS and 50% larger ES and SD. Also, I saw slight ejector marks. I'll retest it with 41.6grs next time.

The Lapua load fell apart with ES and SD doubling but I used fireformed brass this time. I'll retest with 42.0 grs.

Finally, look at the group size: the low ES/SD loads shot the worst groups, especially the Winchester one. I got the numbers down but the group still sucks. The 41.5gr load shoots groups half this size but the ES is 50 FPS. So what's better?

It looks like the MK316 brass is just another variant of FGMM commercial brass. It weighs 176grs and has the same water capacity and neck thickness. It gives the same velocity, ES and SD.

It is NOT the same as LC LR. Look at the velocity difference: 20 FPS and 50% larger ES and SD. Also, I saw slight ejector marks. I'll retest it with 41.6grs next time.

The Lapua load fell apart with ES and SD doubling but I used fireformed brass this time. I'll retest with 42.0 grs.

Finally, look at the group size: the low ES/SD loads shot the worst groups, especially the Winchester one. I got the numbers down but the group still sucks. The 41.5gr load shoots groups half this size but the ES is 50 FPS. So what's better?

41.8 amd 42.2 in LC 12 brass give me the same groups you are looking at, I don't have a chrono but was estimating 2650based on what I read elsewhere.

Shooting through a 10 FP with a McGowan 26" 10 twist.

Shooting through a 10 FP with a McGowan 26" 10 twist.

This powder gives me nice groups throughout the charge weight range.

But it's interesting how two cases with the same capacity (FC and LC) will give you different velocity and ES. Federal does use a different brass alloy and it does make a difference.

But it's interesting how two cases with the same capacity (FC and LC) will give you different velocity and ES. Federal does use a different brass alloy and it does make a difference.

Here's today's tuning:

I cleaned the shit out of the barrel last night. That turned out to be a bad idea. It took the first group to season the bore and I got a wild ES of 70. The first group was 41.8grs of IMR4064 in a new FC10 case. The second was 41.7grs which turned out to be better. But when I tried the 41.8gr load in a fireformed FC10 case, the load fell apart. It needs a .2gr charge weight reduction.

As I predicted, the 42.2gr load in a new Lapua case, when reduced by .2grs, does the same thing in a fireformed Lapua case. Therefore, I will reduce the 41.8gr load in the fireformed FC10 case to 41.6grs.

Check out the LC13LR load! ES13 SD5! That's the shit right there.

Oh, BTW, these are with the Magnetospeed attached.

I cleaned the shit out of the barrel last night. That turned out to be a bad idea. It took the first group to season the bore and I got a wild ES of 70. The first group was 41.8grs of IMR4064 in a new FC10 case. The second was 41.7grs which turned out to be better. But when I tried the 41.8gr load in a fireformed FC10 case, the load fell apart. It needs a .2gr charge weight reduction.

As I predicted, the 42.2gr load in a new Lapua case, when reduced by .2grs, does the same thing in a fireformed Lapua case. Therefore, I will reduce the 41.8gr load in the fireformed FC10 case to 41.6grs.

Check out the LC13LR load! ES13 SD5! That's the shit right there.

Oh, BTW, these are with the Magnetospeed attached.

dang it dan, you've let the secret out. thats been my load for the .308 since i switched to berger 175 otm's. 41.7gns. 4064 with a fed. match primer but i use lake city cases. out of my 20" barrel my best 5 shot group at 100 to date has been .129. there were a lot of factors involved, wind, rifle, scope, and luck but its consistantly a fat quarter to a half inch load. it runs right at 2560 with no signs of pressure and tommorow were going to put it on paper at 1150

Just back from range shot 42.2 4064 in Lapua brass on its 7th firing, 175 SMK and 178 AMAX, 10 shot group in one hole about a 3/4 inch from edge to edge.

Just back from range shot 42.2 4064 in Lapua brass on its 7th firing, 175 SMK and 178 AMAX, 10 shot group in one hole about a 3/4 inch from edge to edge.

Very nice! What gun you shooting it out of?

Great info on the FC military brass versus the commercial Gold Medal stuff. That stands to reason, and it's good to see it confirmed.

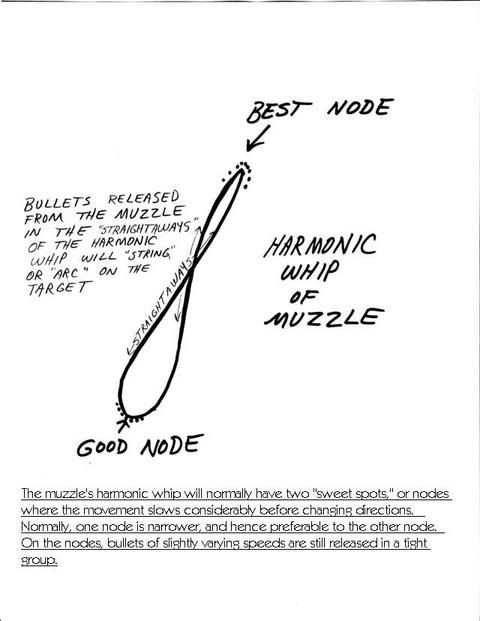

Neck tension on the cases can be a big factor as to ES numbers, and accuracy too of course. When we see tight groups at 100 yards with wide velocity spreads, we've got to figure out how the bullets could exit the muzzle when it is bending toward the same direction for every shot, but somehow barrel time is widely different (barrel time meaning how much time the bullet spends in the barrel, which is direction proportional to muzzle velocity).

Those bullets which group tight in spite of a wide velocity spread would be exiting the muzzle when it's reaching the end of the vibration sweep, and stopping (a nanosecond or two?) and then moving back in the other direction. The muzzle is sitting "almost" still for a period of time, and this provides a wide window of opportunity where bullets with varying barrel times can emerge from the bore at the same point in space... and consequently end up on the 100 yard target in the same place.

Such a load will work well at close range but of course strings out pretty bad as range increases. A member here posted some documents of a 600 yard match win with a non-optimal load recipe. He shot well and doped the wind well to win that match--but the vertical dispersion at 600 yards showed what his 100 yard target could not--a wide spread in velocity. Had the match been a 1000 yard contest, things would certainly not have gone nearly so well with that load.

The ideal is to have a tight ES and also have the bullets exiting on a stable "end node" of the muzzle's vibration pattern. But if you can have just one or the other, take the tight numbers, even with a slightly larger group. A 1.5 MOA 100 yard group with tight numbers would theoretically shoot 1.5 MOA all the way down range (all other factors being the same or notwithstanding)... but a 1/2 MOA group with a wide ES would string vertically very badly at longer ranges, so would of course not be preferable. Good factory match load recipes don't always amaze us at 100 yards, but they seem to deliver the goods farther out...

In a standard OCW test, with groups on either side of the suspected OCW node printing into the same POI (point of impact), the norm is tight ES in the center of that node, and a load recipe using that same amount of powder nearly always makes a decent long range load recipe.

Slight adjustments of bullet seating depth will help to tighten up groups which in spite of good chronograph numbers don't print as tightly as you'd like. Tuning the seating depth can also help to bring the cold, clean bore point of impact closer (or in some cases "dead onto") the following group.

Dan

Neck tension on the cases can be a big factor as to ES numbers, and accuracy too of course. When we see tight groups at 100 yards with wide velocity spreads, we've got to figure out how the bullets could exit the muzzle when it is bending toward the same direction for every shot, but somehow barrel time is widely different (barrel time meaning how much time the bullet spends in the barrel, which is direction proportional to muzzle velocity).

Those bullets which group tight in spite of a wide velocity spread would be exiting the muzzle when it's reaching the end of the vibration sweep, and stopping (a nanosecond or two?) and then moving back in the other direction. The muzzle is sitting "almost" still for a period of time, and this provides a wide window of opportunity where bullets with varying barrel times can emerge from the bore at the same point in space... and consequently end up on the 100 yard target in the same place.

Such a load will work well at close range but of course strings out pretty bad as range increases. A member here posted some documents of a 600 yard match win with a non-optimal load recipe. He shot well and doped the wind well to win that match--but the vertical dispersion at 600 yards showed what his 100 yard target could not--a wide spread in velocity. Had the match been a 1000 yard contest, things would certainly not have gone nearly so well with that load.

The ideal is to have a tight ES and also have the bullets exiting on a stable "end node" of the muzzle's vibration pattern. But if you can have just one or the other, take the tight numbers, even with a slightly larger group. A 1.5 MOA 100 yard group with tight numbers would theoretically shoot 1.5 MOA all the way down range (all other factors being the same or notwithstanding)... but a 1/2 MOA group with a wide ES would string vertically very badly at longer ranges, so would of course not be preferable. Good factory match load recipes don't always amaze us at 100 yards, but they seem to deliver the goods farther out...

In a standard OCW test, with groups on either side of the suspected OCW node printing into the same POI (point of impact), the norm is tight ES in the center of that node, and a load recipe using that same amount of powder nearly always makes a decent long range load recipe.

Slight adjustments of bullet seating depth will help to tighten up groups which in spite of good chronograph numbers don't print as tightly as you'd like. Tuning the seating depth can also help to bring the cold, clean bore point of impact closer (or in some cases "dead onto") the following group.

Dan

Dan, I had to update this thread based on information you provided for Nosler brass back in February. I asked what the node load should be with IMR4064 and you replied for Nosler 41.8gr. Based on that info I decided to run a little mini OCW test for 41.6 to 42.0 in .1 gr increments.

Ran it today and the results are below. Dan, I do believe you were spot on!

Velocities - 22" barrel

41.6 - 2442, 2415, 2455

41.7 - 2446, 2464, 2469

41.8 - 2482, 2473, 2482

41.9 - 2492, 2496, 2510

42.0 - 2487, 2515, 2506

Average fired case capacity 56.7gr water

Ran it today and the results are below. Dan, I do believe you were spot on!

Velocities - 22" barrel

41.6 - 2442, 2415, 2455

41.7 - 2446, 2464, 2469

41.8 - 2482, 2473, 2482

41.9 - 2492, 2496, 2510

42.0 - 2487, 2515, 2506

Average fired case capacity 56.7gr water

Attachments

Last edited:

Velocities - 22" barrel

41.6 - 2442, 2415, 2455

41.7 - 2446, 2464, 2469

41.8 - 2482, 2473, 2482

41.9 - 2492, 2496, 2510

42.0 - 2487, 2515, 2506

Average fired case capacity 56.7gr water

Could you also share your firearm info and fired case dimensions: base, shoulder and neck diameter?

Could you also share your firearm info and fired case dimensions: base, shoulder and neck diameter?

Sure!

Remington 700 accurized and chambered by LRI, Bartlein #13 Remington varmint/Sendero contour, 11.25 twist, 22".

Base to shoulder on the fired brass is 1.638"; neck diameter .345"

Last edited:

Thanks but I meant the diameters: base diameter at the expansion ring and the shoulder diameter.

Thanks but I meant the diameters: base diameter at the expansion ring and the shoulder diameter.

Sorry I misread the original question. Diameter at the expansion ring is .469" and shoulder diameter .457"

Cool. That means your chamber is dimensionally similar to a Remington factory chamber and will yield similar water capacity values for the brass.

To me it looks like Nosler brass is similar to Federal Gold Medal even though it weighs less.

To me it looks like Nosler brass is similar to Federal Gold Medal even though it weighs less.

Interested how this powder is in different temps. This might of already been covered but I missed it. I shoot in -20-100' temps and have had major issues with imr4895.

I have not done any comparisons yet, but the MK316 mod is supposed to use IMR 4064 because of the temp sensitivity of RE15 so it should give more consistent results. During some of Black Hills development testing I believe they only saw a 20FPS change in velocity over the entire span of temps tested.

20fps is definitely acceptable. I have been trying h4895 and now varget. They claim that they are extreme powders that can handle temp changes well.

Interested how this powder is in different temps. This might of already been covered but I missed it. I shoot in -20-100' temps and have had major issues with imr4895.

I tested it against Varget in -5 degrees F and it was perfect--no advantage to the Varget at all, even out to 1040 yards. Velocity (determined not from a chronograph which may or may not be right, but from actual bullet drop)--held strong for both powders.

Haven't checked the hot weather performance as of yet, but I think with a modest charge (which is what the FGMM and the Mk316 are using) there shouldn't be any issues of pressure problems with the 4064.

Dan

Haven't checked the hot weather performance as of yet, but I think with a modest charge (which is what the FGMM and the Mk316 are using) there shouldn't be any issues of pressure problems with the 4064.

Dan

I'd be interested in seeing some hot weather testing with the IMR 4064. I was surprised the Military decided to go with IMR 4064 instead of some newer powder. I would only guess the 4064 did better than Reloader 15 in the higher temperatures.

The article is a good read. In this excerpt, the author states 20 propellants were tested and after finding the propellant that gave them the 21 FPS variance they wanted, they added Calcium Carbonate to it to reduce muzzle flash.

"Firing cartridges heated to 165 degrees, and others cooled to 25 below zero, his ballistics lab found a muzzle velocity variance of 227 f.p.s.; each degree of temperature change caused a 11/2-f.p.s. change of muzzle velocity. At 800 meters that meant a trajectory variance of 58 inches. Hoffman and the Navy evaluated more than 20 propellants and blends to find a temperature-stabilized propellant that varied only 21 f.p.s. between those temperature extremes. In addition, calcium carbonate was added to reduce muzzle flash. When Federal Cartridge began producing the updated 175-gr. load—now called the Mk 316 Mod 0 due to being a Navy development—the Crane Center test-fired five lots at 300 yds.; they grouped an impressive 1.75 inches, or 0.58 m.o.a."

I believe the propellant they chose was a non canister available IMR 4064 with the added flash reducer made to the military specs. What do I know, I may be wrong, but I would still like to see Dan Newberry or someone else test a newer lot of IMR 4064 in temperature extremes (high heat) to actually see if the newer / current lots of IMR 4064 available to us hand loaders has the very low temperature variance as witnessed by the Military.

I've had IMR 3031 give me pressure issues in high heat. I've read nothing about the IMR series of rifle powders being reformulated over the years to be less temperature sensitive.

"Firing cartridges heated to 165 degrees, and others cooled to 25 below zero, his ballistics lab found a muzzle velocity variance of 227 f.p.s.; each degree of temperature change caused a 11/2-f.p.s. change of muzzle velocity. At 800 meters that meant a trajectory variance of 58 inches. Hoffman and the Navy evaluated more than 20 propellants and blends to find a temperature-stabilized propellant that varied only 21 f.p.s. between those temperature extremes. In addition, calcium carbonate was added to reduce muzzle flash. When Federal Cartridge began producing the updated 175-gr. load—now called the Mk 316 Mod 0 due to being a Navy development—the Crane Center test-fired five lots at 300 yds.; they grouped an impressive 1.75 inches, or 0.58 m.o.a."

I believe the propellant they chose was a non canister available IMR 4064 with the added flash reducer made to the military specs. What do I know, I may be wrong, but I would still like to see Dan Newberry or someone else test a newer lot of IMR 4064 in temperature extremes (high heat) to actually see if the newer / current lots of IMR 4064 available to us hand loaders has the very low temperature variance as witnessed by the Military.

I've had IMR 3031 give me pressure issues in high heat. I've read nothing about the IMR series of rifle powders being reformulated over the years to be less temperature sensitive.

The full article in American Rifleman was a good write up if you can get your hands on a copy. I have been working with this and RE15 for loads in my REM 700 AAC-SD. The gun is just starting to get broken in but the results have been promising so far. I intend to do some testing later this spring or into summer when the temps start to climb. West Texas should give us some warm to hot weather in the next few months. I will post the results when the weather cooperates.

The article is a good read. In this excerpt, the author states 20 propellants were tested and after finding the propellant that gave them the 21 FPS variance they wanted, they added Calcium Carbonate to it to reduce muzzle flash.

I believe the propellant they chose was a non canister available IMR 4064 with the added flash reducer made to the military specs. What do I know, I may be wrong, but I would still like to see Dan Newberry or someone else test a newer lot of IMR 4064 in temperature extremes (high heat) to actually see if the newer / current lots of IMR 4064 available to us hand loaders has the very low temperature variance as witnessed by the Military.

I've had IMR 3031 give me pressure issues in high heat. I've read nothing about the IMR series of rifle powders being reformulated over the years to be less temperature sensitive.

I would be interested in that data as well as the charge weight of whatever powder it may be.

I do have a chart of velocity spread over 125 degrees F range.

Best are H4350: 4 fps, Varget: 8 fps, and H4831: 20 fps.

Worst are N560: 121 fps, IMR 4831: 127 fps, and IMR 4895: 166 fps.

IMR 4350 is 67 fps, so about in the middle.

IMR 3031 is not one of the powders tested.

Unfortunately, I have lost the source of these data.

There is something different between the FGMM and M118LR...nobody is taking into consideration the laquer type sealant used on the M118LR neck. Somewhere in my pile of data I will find the spec. There is no crimp but that sealant has to change things

Pulled a few of my 175 FGMM and when I reseated the bullet it made a slight crunch of a compressed load. Don't have my data in front of me but that was a first. Anyone else experience this? OAL confirmed 2.800

Just received a few boxes of FGMM 175's today. I pulled the rounds and measured the powder at 42.7g 4064. COAL is 2.820. As far as I could tell its on the verge of being compressed or just is. Anyone else purchase some lately as well and checked the measurement and charge? Their website says their max charge is 45.6g, HTF do you get that much in a .308 case?

Very good thread! Thank you to all who have posted information here. I was able to work a great load using once fired FGMM brass at 42gr of 4064 and will be working a new load this weekend with Lapua brass starting at 41.7grs and working up.

Very good thread! Thank you to all who have posted information here. I was able to work a great load using once fired FGMM brass at 42gr of 4064 and will be working a new load this weekend with Lapua brass starting at 41.7grs and working up.

Try 41.8 as well. That grouped better for me

Just got some new FGMM 308 175gr ammo the other day, so I decided to pull one down just to compare. The brass looked like standard FGMM brass, the bullet was a run of the mill 175 Sierra MK and the powder certainly looked identical to IMR-4064. However when I weighed it, it was 42.6gr. Has something changed?? I thought the standard FGMM load with IMR-4064 was 41.7.

Try 41.8 as well. That grouped better for me

I tried this today and it worked great! I am loading some more up at 42gr to try in the next few days.

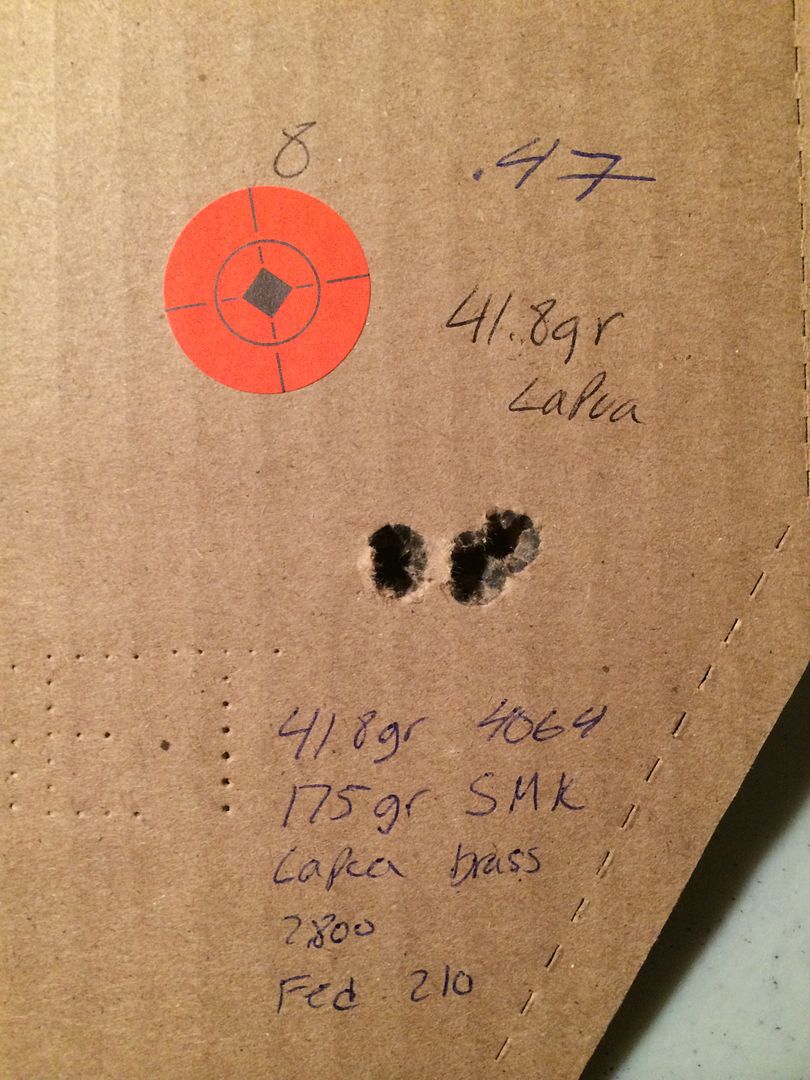

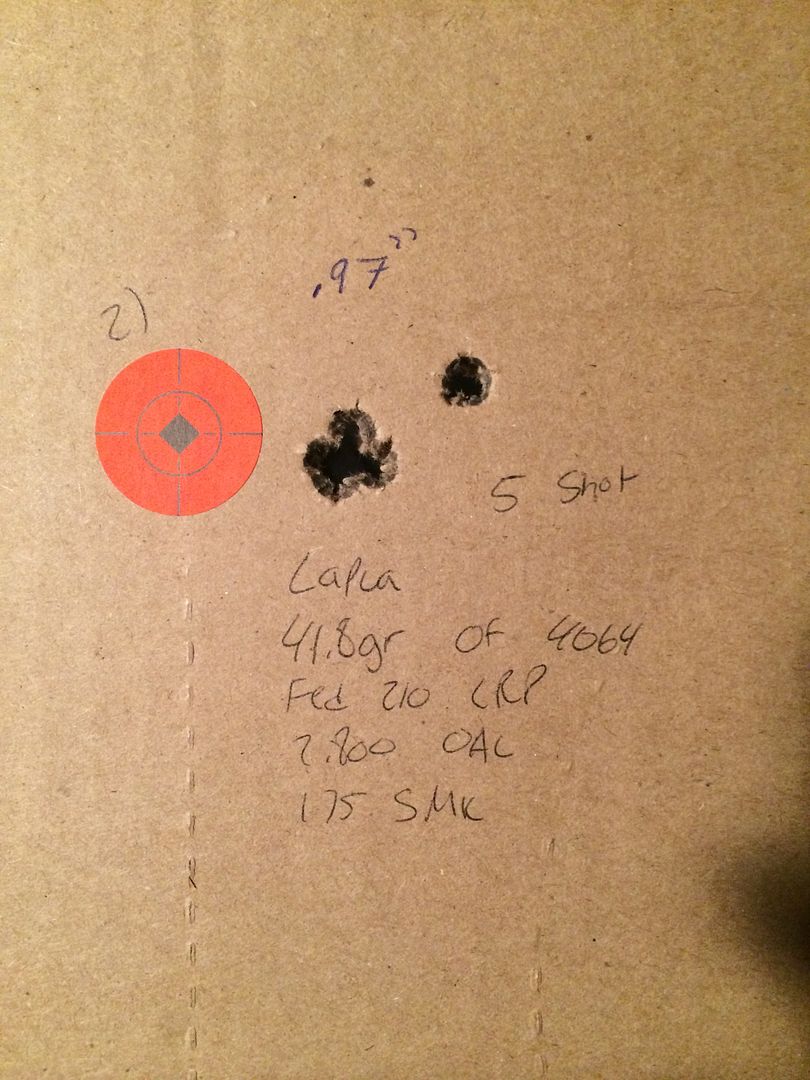

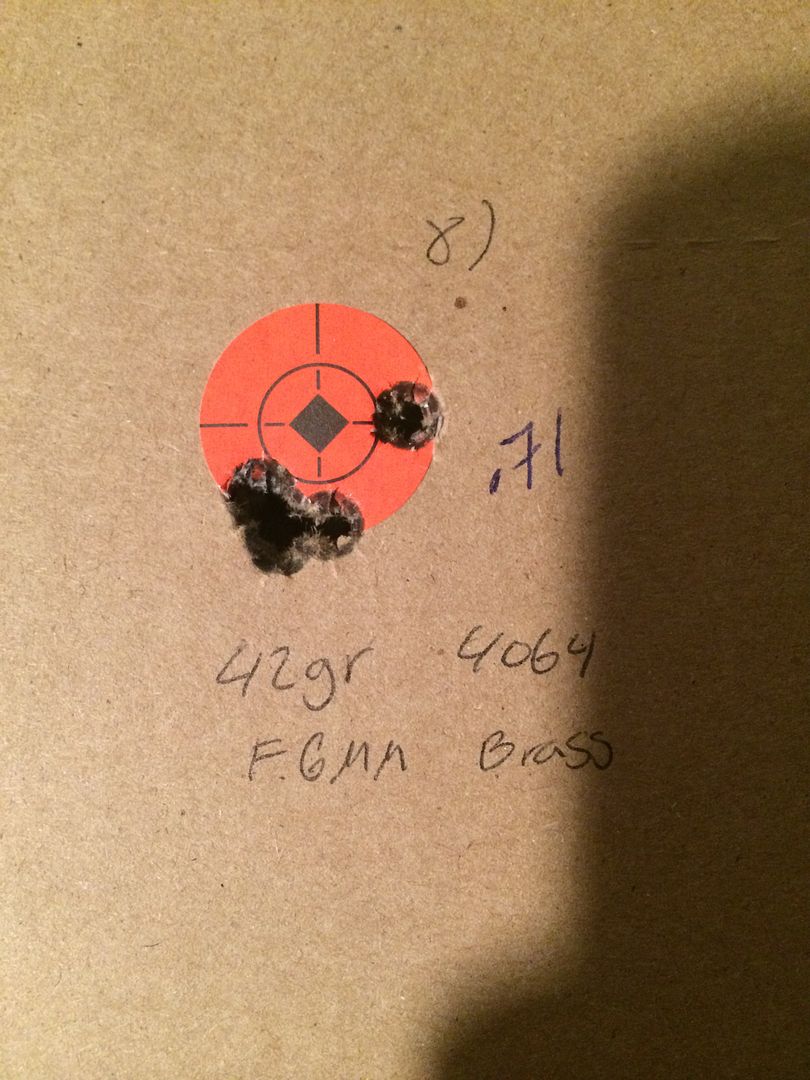

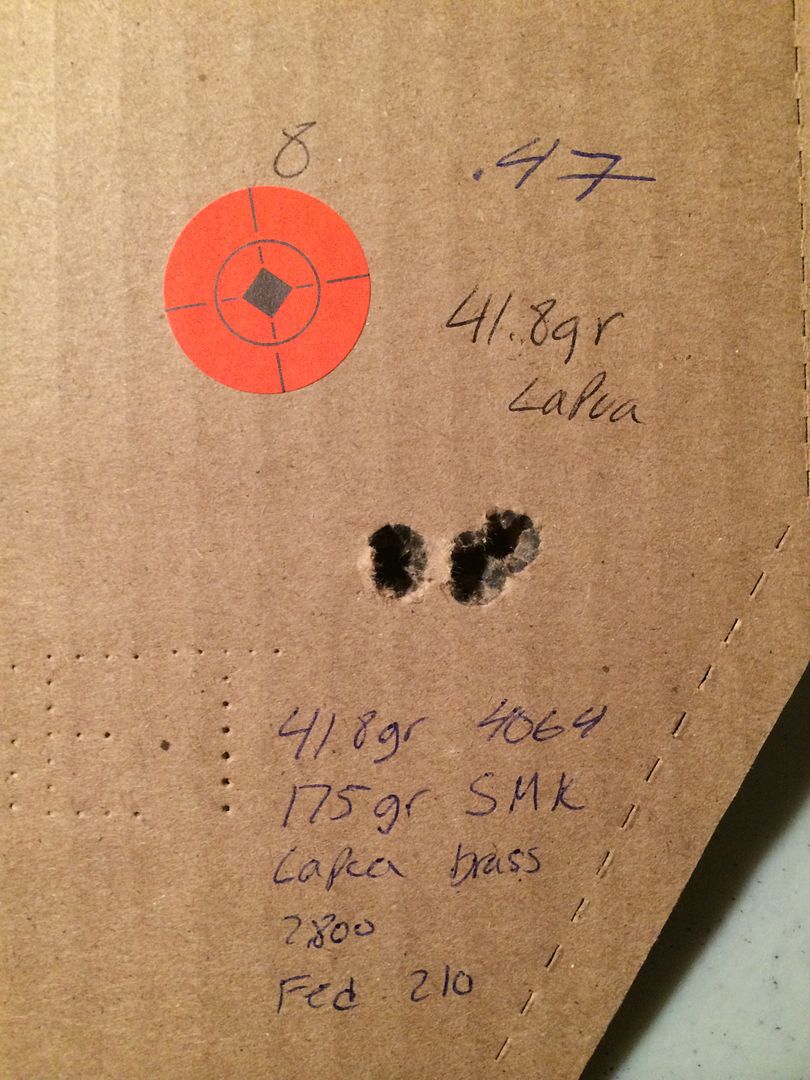

Here is some more data that may be able to held some people out. So far, I really like the 4064 powder. Ive been working this load the past few weeks with both Federal and Lapua brass. The speeds are coming in pretty low so I need to work a faster hotter load for my long shots. The farthest I can shoot locally is 710 yards and they do stay consistant to that distance.

Rifle specs:

Factory Remington 700 SPS 20"

Manners T4A w/ mini chassis

Timney Calvin Elite trigger

Larue 20 MOA base

MK4 rings

NF 5.5-22x50

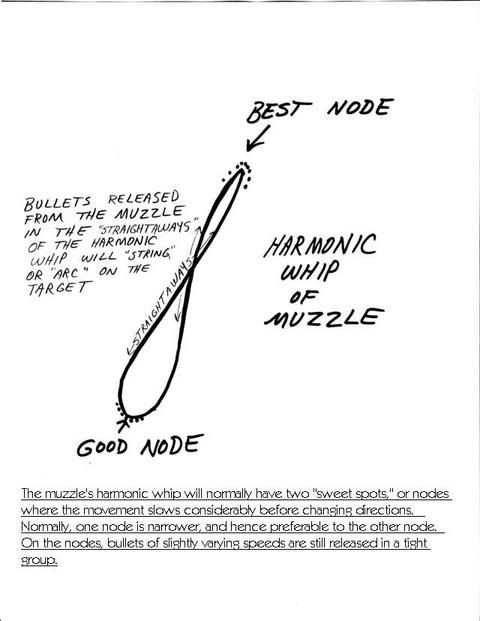

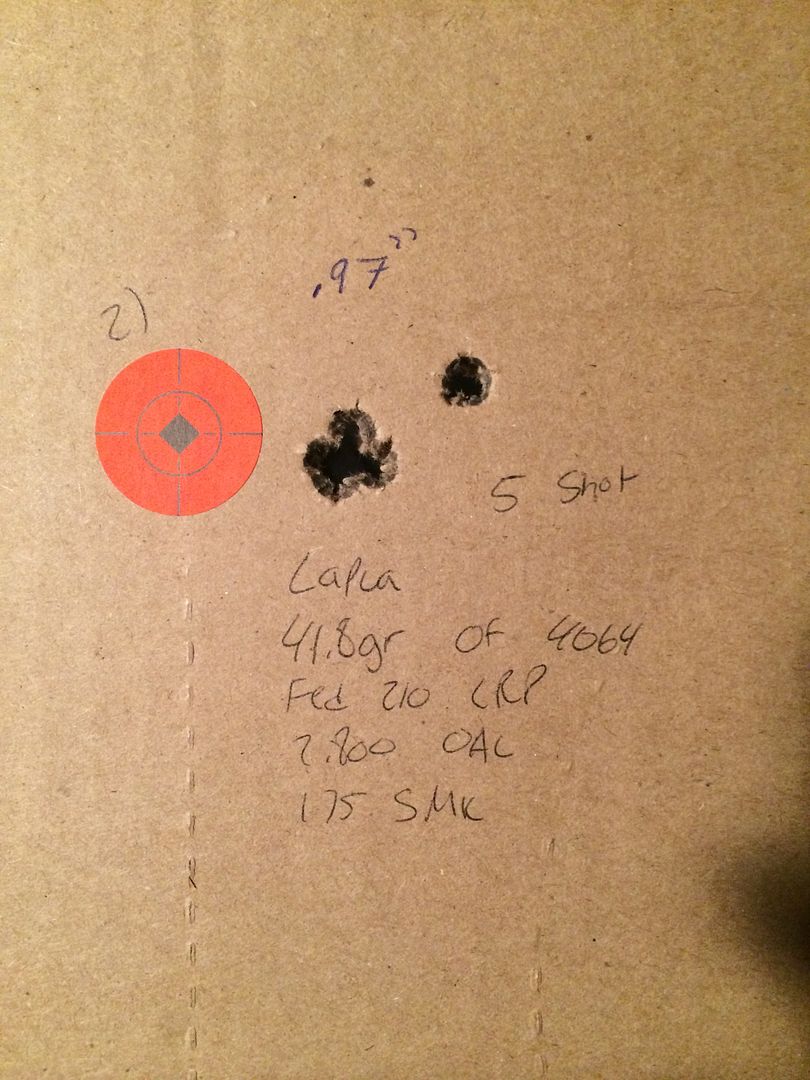

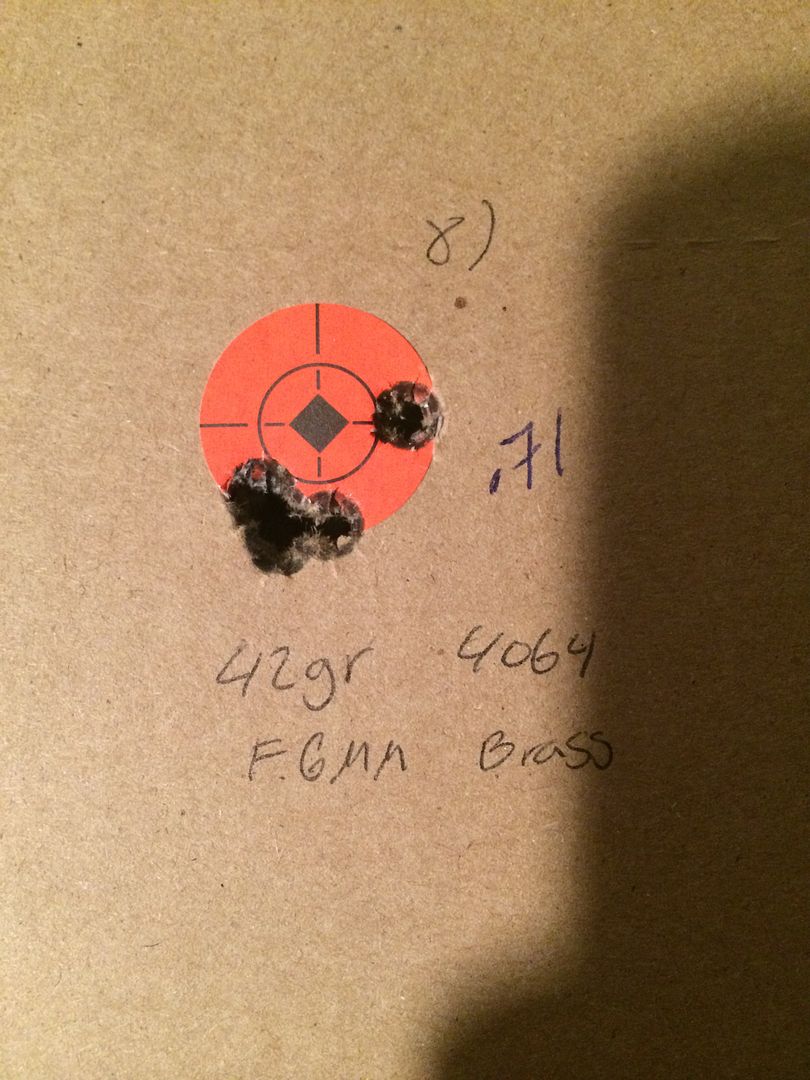

These groups were shot off of a bipod and a rear bag.

The specs for all the rounds are the same. The only difference is the powder charge and brass

FGMM brass

42gr of 4064

OAL 2.800

Federal 210 primer

Lapua brass

41.8gr of 4064

OAl 2.800

Federal 210 primer

These two loads have given me the best results so far. Ive tried both the Lapua brass and FC brass up to 42.6gr and the higher I go the worse the groups get. This isnt near max yet so I have more load working to do.

Here are some velocities of the loads that have worked best in my rifle.

Federal Brass loaded at 42gr of 4064

2510

2510

2525

Lapua brass at 41.8gr

2478

2482

2479

Rifle specs:

Factory Remington 700 SPS 20"

Manners T4A w/ mini chassis

Timney Calvin Elite trigger

Larue 20 MOA base

MK4 rings

NF 5.5-22x50

These groups were shot off of a bipod and a rear bag.

The specs for all the rounds are the same. The only difference is the powder charge and brass

FGMM brass

42gr of 4064

OAL 2.800

Federal 210 primer

Lapua brass

41.8gr of 4064

OAl 2.800

Federal 210 primer

These two loads have given me the best results so far. Ive tried both the Lapua brass and FC brass up to 42.6gr and the higher I go the worse the groups get. This isnt near max yet so I have more load working to do.

Here are some velocities of the loads that have worked best in my rifle.

Federal Brass loaded at 42gr of 4064

2510

2510

2525

Lapua brass at 41.8gr

2478

2482

2479

Here is some more data that may be able to held some people out. So far, I really like the 4064 powder. Ive been working this load the past few weeks with both Federal and Lapua brass. The speeds are coming in pretty low so I need to work a faster hotter load for my long shots. The farthest I can shoot locally is 710 yards and they do stay consistant to that distance.

Rifle specs:

Factory Remington 700 SPS 20"

Manners T4A w/ mini chassis

Timney Calvin Elite trigger

Larue 20 MOA base

MK4 rings

NF 5.5-22x50

These groups were shot off of a bipod and a rear bag.

The specs for all the rounds are the same. The only difference is the powder charge and brass

FGMM brass

42gr of 4064

OAL 2.800

Federal 210 primer

Lapua brass

41.8gr of 4064

OAl 2.800

Federal 210 primer

These two loads have given me the best results so far. Ive tried both the Lapua brass and FC brass up to 42.6gr and the higher I go the worse the groups get. This isnt near max yet so I have more load working to do.

Here are some velocities of the loads that have worked best in my rifle.

Federal Brass loaded at 42gr of 4064

2510

2510

2525

Lapua brass at 41.8gr

2478

2482

2479

Just for the heck of it I tried using Hornady Match Brass with similar loads 41.8 to 44.00 grains using the 175's and coal from 2.800-2.815. The lower end charges and longer coal yielded the tightest sub .4 groups with less incidence of flyers.

Tried 41.8gr in my DPMS LR the other day. Freaking magic. Picked up another 10lbs. The rifle was just under MOA with slower Varget loads, and went half that the moment I tried the IMR 4064. The only downside I can think of is that I am probably running a pretty slow MV. Haven't chronographed the load yet, but I'm using an 18" barrel.

However, I have found my pest control load now for out at the ranch. Great thread!

However, I have found my pest control load now for out at the ranch. Great thread!

Some of this is good news. To me, some of this is old news.

http://www.snipershide.com/shooting/snipers-hide-reloading/100218-168-fgmm-unlocked.html#post1444726

http://www.snipershide.com/shooting/snipers-hide-reloading/100218-168-fgmm-unlocked.html#post1444726

Okay... the self appointed mall cops of reloading might want to go watch a rerun of Gomer Pyle about now...

For the rest of us, here's a short video we made today...

Sleuthing the Federal Gold Medal Match long range load recipe. - YouTube

Dan

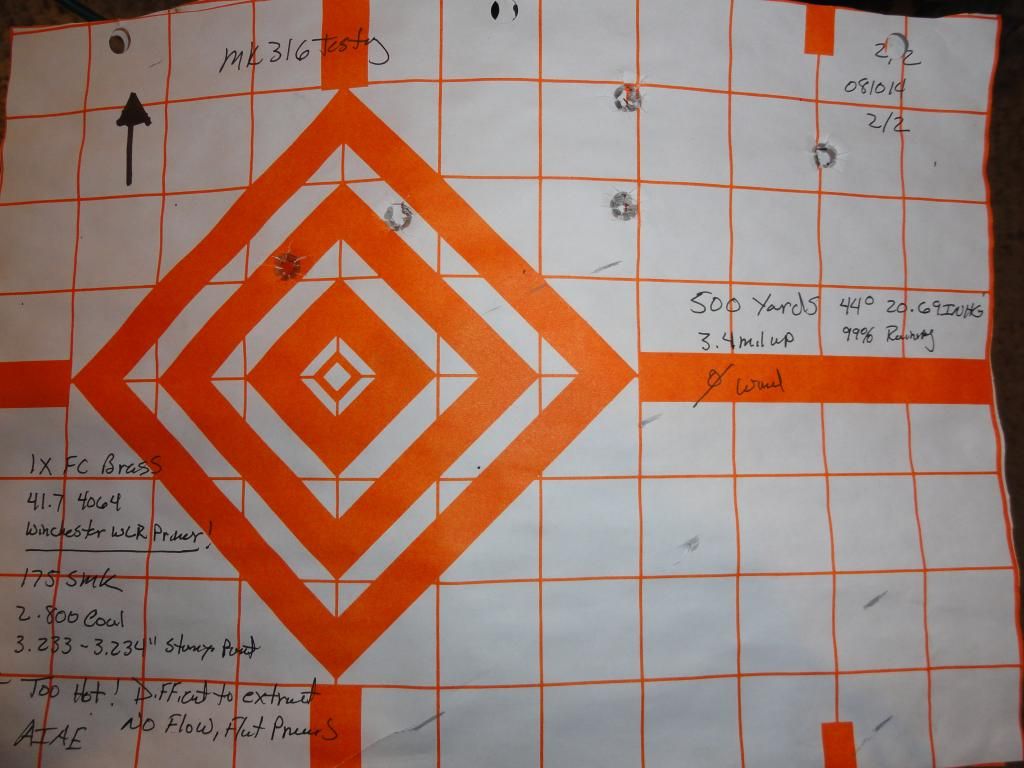

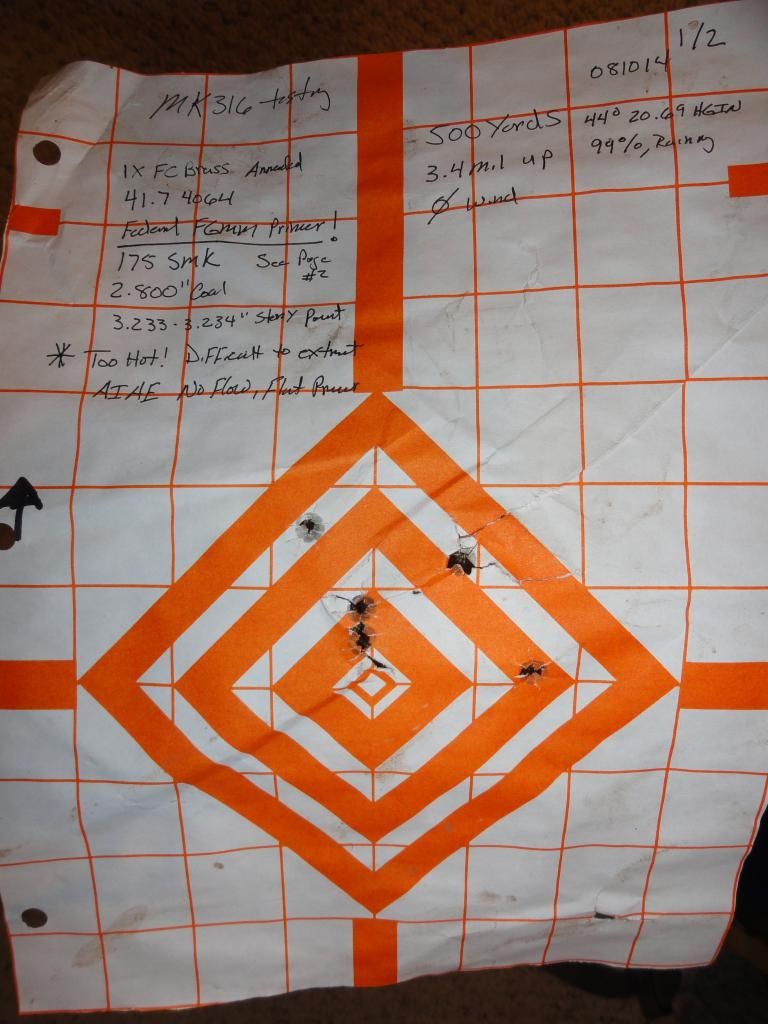

Here are some interesting findings regarding this clone:

*Both groups fired at 500 yards*

1 Fired FC Annealed, WLR Primer, 175 SMK @ 2.800" 41.7 4064

1 Fired FC Annealed, FGMM Primer, 175 SMK @ 2.800" 41.7 4064

Both were too hot for my gun, difficulty extracting, flat primers, no flow

When I weighed the above loads compared to factory 175 FGMM my loaded cartridges weighed 399.5

grains to 400.5 Factory FGMM weighed nearly identical within .5 of 400.0 grains

I am going to drop charge weight a bit and see if I get rid of the sticky extraction.

FPS, based on drop was +- 2550 whereas FGGM was closer to 2500

Lastly, Primer appears to make a fairly large difference

Rprecision, what rifle are you using? That load should be on the mild side... could it be the brass just needs to be FL sized fully? What about Federal factory GMM, does it show any pressure signs when you shoot it (or have you tried it yet)?

Rprecision, what rifle are you using? That load should be on the mild side... could it be the brass just needs to be FL sized fully? What about Federal factory GMM, does it show any pressure signs when you shoot it (or have you tried it yet)?

Its a AI AE MKIII running a AINA 1/10 Bartlien 5r, 18.5" Barrel, TBAC 30-P1.

These cases are full length sized, Trimmed to 2.000" shoulder bumped back .003-004" with a Forester FL Match Die. They don't have any problems going in......

Of the 60 Rounds of 175 FGGM I have, I have shot 10, which shot very well 1/4 MOA, with zero pressure signs.

I was going through the brass shot above and one of the WLR loads has a ejector swipe.

In other load development the gun usually shows pressure signs before published or known max data, just never seen it .2 grains over start (41.5 Published)

I'm all ears if you got suggestions, I know FC brass is not great, I just happen to have a pile of it.

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 0

- Views

- 109

- Replies

- 2

- Views

- 1K

- Replies

- 1

- Views

- 353