Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Welding and Metalworking Thread

- Thread starter bogeybrown

- Start date

Haven't seen much activity here so I thought I would mention that I took a production welding job as a quick move to get out of a maintenance position that wasn't good for my health. I have to say production welding isn't my thing but it's a paycheck until I get shut figured out. Here's one of my welds, first time running spray transfer. Have to say that I like the way it lays down.

Attachments

I've not done "that" particular type of MIG welding before, and actually had to look it up! I obviously don't know everything, and found it interesting that there are 'different' ways to MIG weld. Compared to how I was taught (almost 35 years ago) and the advancements made in all that time, I'd say that it was "too hot and too fast". After reading a bit about it, WOW,,,,, I can only imagine what it was like to see it get laid down.

I've very little experience at all with "production welding" whereas all of my background/training has been on "on-site repair" as well as "shop custom fabrication" so neither venue would have such a process.

Thanks for the lesson this morning. It made my coffee that much more enjoyable. I appreciate learning.

I'm working on saving up some scratch to get myself a suitcase TIG welder, just so that I can accomplish a hobby-project that I've wanted to do for a few decades now. But that's a whole 'nuther story.

I've very little experience at all with "production welding" whereas all of my background/training has been on "on-site repair" as well as "shop custom fabrication" so neither venue would have such a process.

Thanks for the lesson this morning. It made my coffee that much more enjoyable. I appreciate learning.

I'm working on saving up some scratch to get myself a suitcase TIG welder, just so that I can accomplish a hobby-project that I've wanted to do for a few decades now. But that's a whole 'nuther story.

I've not done "that" particular type of MIG welding before, and actually had to look it up! I obviously don't know everything, and found it interesting that there are 'different' ways to MIG weld. Compared to how I was taught (almost 35 years ago) and the advancements made in all that time, I'd say that it was "too hot and too fast". After reading a bit about it, WOW,,,,, I can only imagine what it was like to see it get laid down.

I've very little experience at all with "production welding" whereas all of my background/training has been on "on-site repair" as well as "shop custom fabrication" so neither venue would have such a process.

Thanks for the lesson this morning. It made my coffee that much more enjoyable. I appreciate learning.

I'm working on saving up some scratch to get myself a suitcase TIG welder, just so that I can accomplish a hobby-project that I've wanted to do for a few decades now. But that's a whole 'nuther story.

I used to work on heavy equipment for a long time then built service trucks the last 6 years. I knew about it but never had the right gas to do it. It's definitely hot and fast, I'm running 29 volts, 550 wire speed with .045 wire to give you an idea of the speed. Definitely not welding out of position with it so it is pretty limited.

I used to work on heavy equipment for a long time then built service trucks the last 6 years. I knew about it but never had the right gas to do it. It's definitely hot and fast, I'm running 29 volts, 550 wire speed with .045 wire to give you an idea of the speed. Definitely not welding out of position with it so it is pretty limited.

Dual shield Flux core is even faster than that. Similar parameters.

Dual shield Flux core is even faster than that. Similar parameters.

I've never ran that before.

Yeah you can lay dual shield down faster and run it in more positions. Sometimes metal core is better depending on the application, it's a lot cleaner process than dual shield so you can save time on coatings prep in a production setup.Dual shield Flux core is even faster than that. Similar parameters.

I used to have machines with hard wire, Ultracore, and Metalshield ready to go. Grab the stinger you need for the job and go.

An old one from when I ruptured my Achilles tendon.

Trying to get the boat ready for when it healed.

How do you like the push/pull gun? Never ran one it was either tig or spoolmatic but i always wanted to try one.View attachment 7070103

An old one from when I ruptured my Achilles tendon.

Trying to get the boat ready for when it healed.

Today. Couldn’t get these jaw plate wedges out for the life of me. Had to weld grade8 bolts and try to pull them up with a 3/4” impact. Still didn’t work. Ran a rosebud tip on them for 10 minutes straight and shocked them with cold water. That worked! Prior to the water, I probably stripped threads out on at least 5 grade 8 1” bolt heads. Wtf!

And for those wondering, im flipping jaws on a concrete/aggregate cusher here.

And for those wondering, im flipping jaws on a concrete/aggregate cusher here.

Attachments

The pic almost looks set up to show how you broke your foot by having the hitch fall on it.View attachment 7070103

An old one from when I ruptured my Achilles tendon.

Trying to get the boat ready for when it healed.

All that’s left is to let the paint dry and drill the top plate

Is that Escanaba the same one from the Movie with Jeff Daniels?View attachment 7070287Building a removable base for a light tower that we’re adding to the back of one of our trucks. It will help with tearing down at night on some of our dark lots.View attachment 7070288

How do you like the push/pull gun? Never ran one it was either tig or spoolmatic but i always wanted to try one.

ive run the cobramatic for a push pull mig and the spoolomatic. it verses the spoolomatic???

you gain a little on weight and access with the push pull, but where i see the biggest advantage is loading the machine with a 35 lb

spool of aluminum vs loading a 1 lb spool in the spoolomatic. when welding a lot, its more efficient in both dollars and time from the reloading of the spool.

this could be argued, i also feel that the spoolomatic is more portable, i run it off of millers wc 115 plugged into the stinger of a welding machine. i can use CC or CV as the wc 115 has a voltage sensing lead. most machines have CV these days so i really dont use the sensing lead very much.

both mig welders run just as good

also, i run with my spool down to the right side, gain mucho on balance and access in tight spots

ive run the cobramatic for a push pull mig and the spoolomatic. it verses the spoolomatic???

you gain a little on weight and access with the push pull, but where i see the biggest advantage is loading the machine with a 35 lb

spool of aluminum vs loading a 1 lb spool in the spoolomatic. when welding a lot, its more efficient in both dollars and time from the reloading of the spool.

this could be argued, i also feel that the spoolomatic is more portable, i run it off of millers wc 115 plugged into the stinger of a welding machine. i can use CC or CV as the wc 115 has a voltage sensing lead. most machines have CV these days so i really dont use the sensing lead very much.

both mig welders run just as good

also, i run with my spool down to the right side, gain mucho on balance and access in tight spots

In that photo all I'm doing is attaching the extrusion that the rubber bump strip hangs off, small tacks every 6" or so. Our usual stuff is flat plate work, and nearly all downhand - I try and set things up so there is no overhead, no clambering on the work or anything too finicky. Seems to work well for us - we've been using the same gear for 8 years and not had any problems. That said, other than when I built the boat nearly all the alloy welding is 2"-4" stitches. I would (probably) change if we were running long welds all day.

Hey! That brings back memories! I used to work for Cedarapids, Inc. We made all kinds of Jaw crushers, Impact crushers, cone crushers. Those plates don’t look to bad.Today. Couldn’t get these jaw plate wedges out for the life of me. Had to weld grade8 bolts and try to pull them up with a 3/4” impact. Still didn’t work. Ran a rosebud tip on them for 10 minutes straight and shocked them with cold water. That worked! Prior to the water, I probably stripped threads out on at least 5 grade 8 1” bolt heads. Wtf!

And for those wondering, im flipping jaws on a concrete/aggregate cusher here.

that is a cute and interesting project you have going there.I love my new home built cnc. lol. View attachment 7070672View attachment 7070670View attachment 7070671

look at the even heat signature through out the weld, perfect

Barney, no disrespect but I gotta ask, is that actually done by hand, or was that an automated process? Either way, it's incredible. But if by hand, then it's "Next Level Human" for sure.

I can see a couple that aren’t quite “perfect” so I’d say some badass did that by hand

Not my work, have a look here: also:https://www.weldporn.com/Barney, no disrespect but I gotta ask, is that actually done by hand, or was that an automated process? Either way, it's incredible. But if by hand, then it's "Next Level Human" for sure.

Well fuck, I thought we had one of the elite welders on here ? I considered myself a good welder until I joined a few Facebook pages filled with this shit. Then I realized that I'm just mediocre ?

I've been too busy welding to post pics of welding, but here's a project I had to do a few weeks ago:

Some aluminum spuds I had to make for a piling barge. I am NOT an aluminum welder, by training nor experience, but I was fairly pleased with how they came out. I used the spool gun that came included with my little multi-process machine, and I continue to fall more in love with how the little guy works.

Some aluminum spuds I had to make for a piling barge. I am NOT an aluminum welder, by training nor experience, but I was fairly pleased with how they came out. I used the spool gun that came included with my little multi-process machine, and I continue to fall more in love with how the little guy works.

Going back to basics this weekend, our son "borrowed" my Mig a year or so ago, since then a few odd jobs have come up around home but not been done. I had to go out today and buy an inverter stick welder for work, liked the look of it so managed a better deal for two kits. Close to fifty years since I used a stick. Plenty of "scrap" in the shed to practice on, just need to not set fire to the facial hair again. A couple of guys around here may twig to what I am talking about, the profile pic was taken after one of Pam's attacks with the scissors.

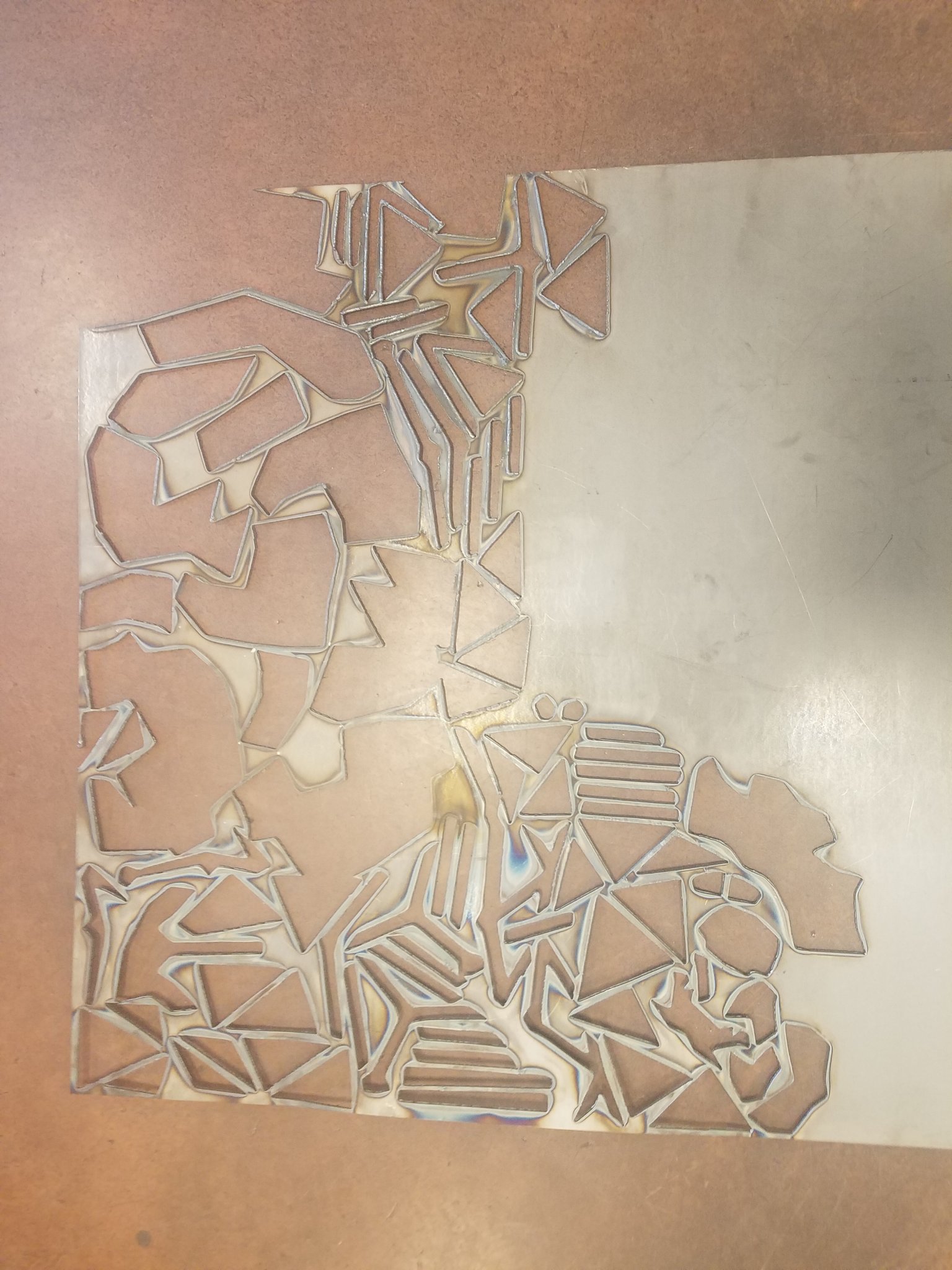

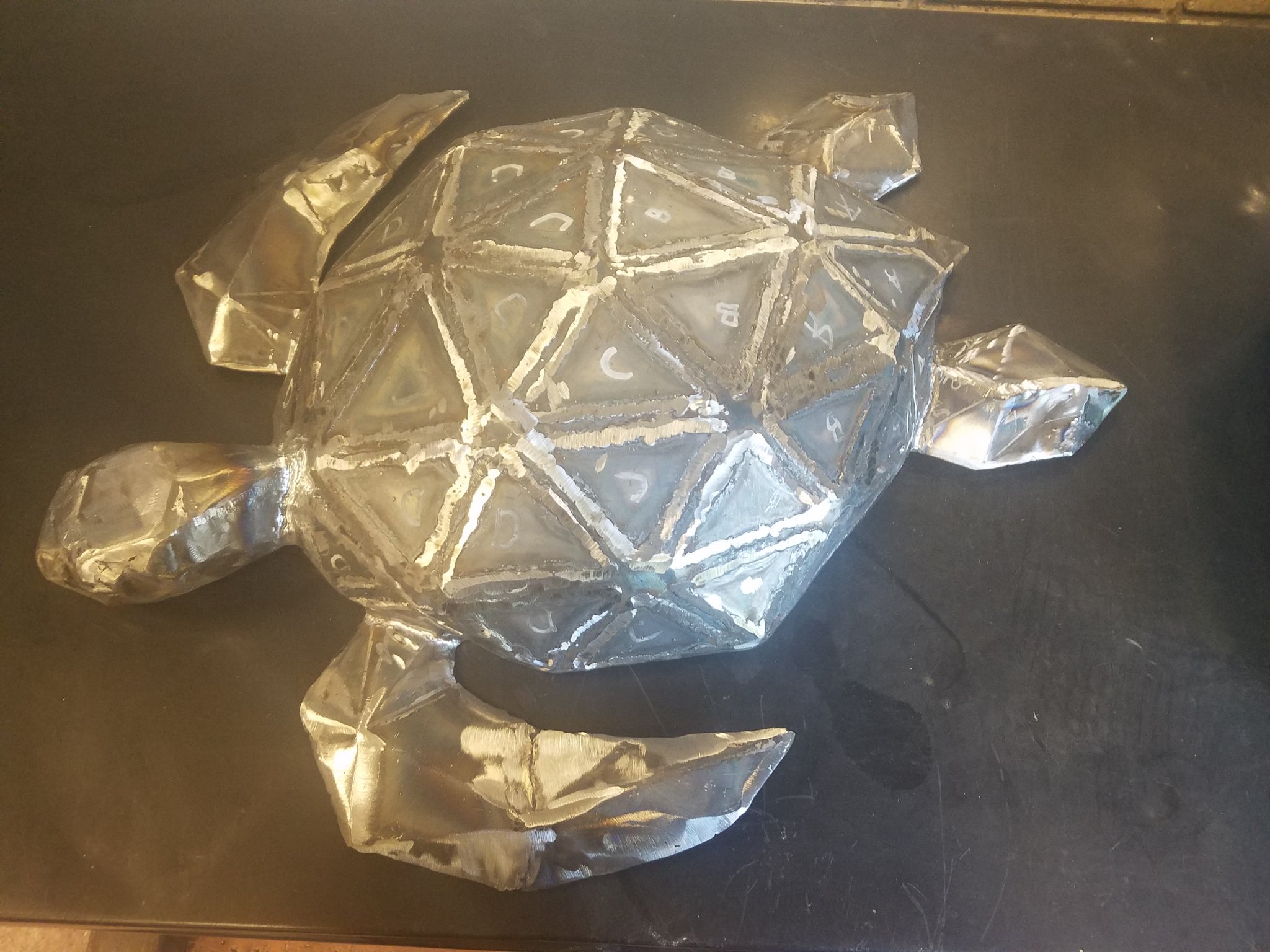

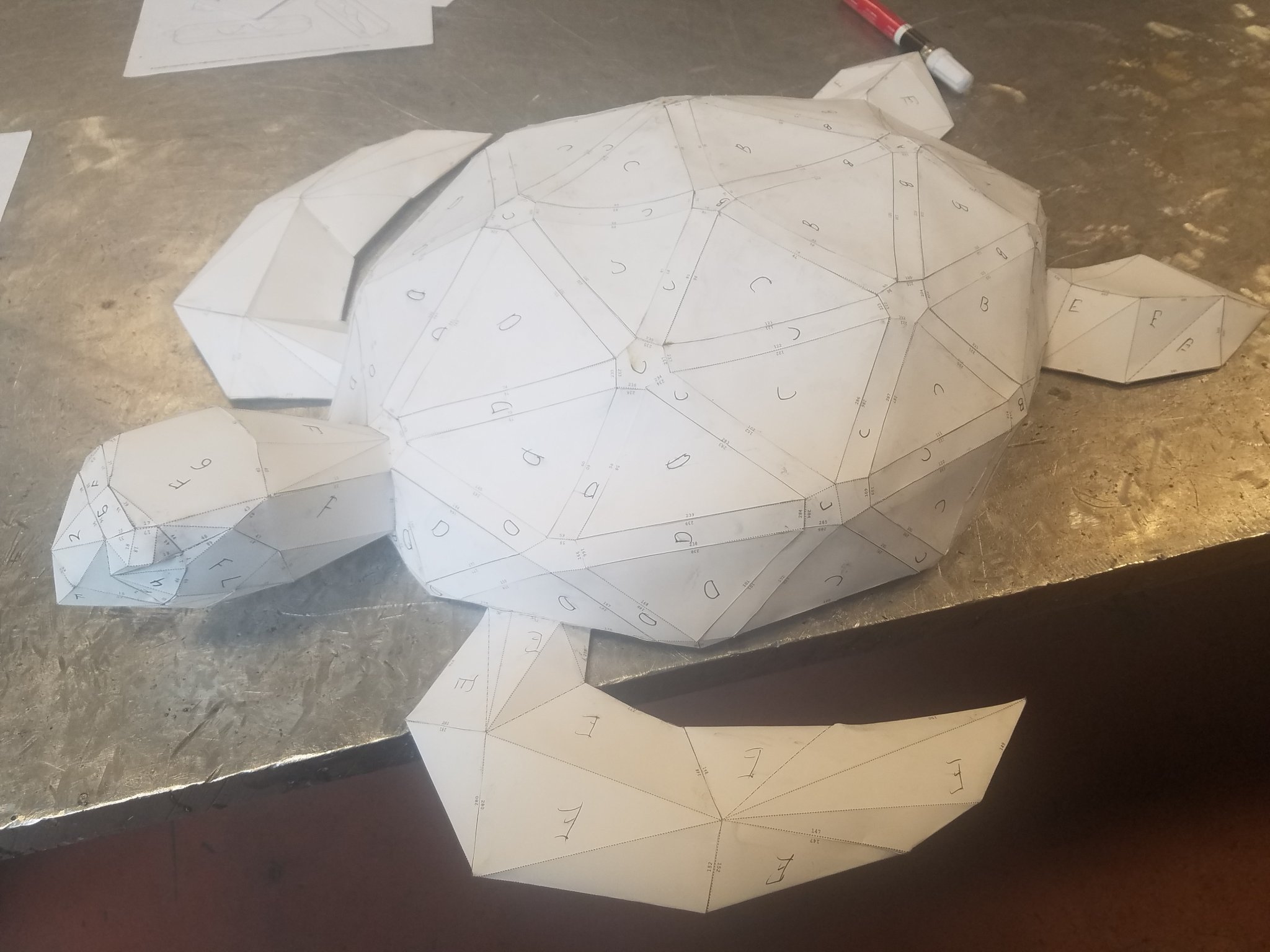

Did this for a fine arts credit in college. 14ga. Tracer plasma for cutting out. Mig for welds. Ground down a little too much. Oxy weld for finish since no one would let me use a tig. Stupid school. Won't let you use a tig unless you are in Welding program. Also doing this after royally screwing up my left thumb. Current pictures at beginning. 23 inches nose to end 21 inches wide. Sheet metal 3 ft tall.

Last edited:

i know the welds aren't the best but it was a ton of fun. Worked from a papercraft model. 96 pieces with 310 edges. Had to bend steel to get it to work. A few of the bends were impossible to bend so I sheared them and welded them. Lots of gaps to weld. Plasma kerf not fun.

i know the welds aren't the best but it was a ton of fun. Worked from a papercraft model. 96 pieces with 310 edges. Had to bend steel to get it to work. A few of the bends were impossible to bend so I sheared them and welded them. Lots of gaps to weld. Plasma kerf not fun.

Going back to basics this weekend, our son "borrowed" my Mig a year or so ago, since then a few odd jobs have come up around home but not been done. I had to go out today and buy an inverter stick welder for work, liked the look of it so managed a better deal for two kits. Close to fifty years since I used a stick. Plenty of "scrap" in the shed to practice on, just need to not set fire to the facial hair again. A couple of guys around here may twig to what I am talking about, the profile pic was taken after one of Pam's attacks with the scissors.

I had to practice stick welding for the maintenance job since it has been about 8 years since I welded with it. My vertical up was pretty rough but part of it was because my welder has an arc control knob. It was quite the learning curve until I figured out where to set it at.

View attachment 7074102View attachment 7074103View attachment 7074104View attachment 7074105i know the welds aren't the best but it was a ton of fun. Worked from a papercraft model. 96 pieces with 310 edges. Had to bend steel to get it to work. A few of the bends were impossible to bend so I sheared them and welded them. Lots of gaps to weld. Plasma kerf not fun.

real good job, if you do more like that, try to weld it w 1/8 6013, low amp, lotta angle.

that is real good work

real good job, if you do more like that, try to weld it w 1/8 6013, low amp, lotta angle.

that is real good work

I haven't messed with 6013, but could you run a 1/8" rod cold enough to not burn through 14ga sheet and still gap-weld those seams?

I could do it with wire, but I personally would need a tighter fit or heavier material to try that with a stick unless it was a comically small electrode

Going back to basics this weekend, our son "borrowed" my Mig a year or so ago, since then a few odd jobs have come up around home but not been done. I had to go out today and buy an inverter stick welder for work, liked the look of it so managed a better deal for two kits. Close to fifty years since I used a stick. Plenty of "scrap" in the shed to practice on, just need to not set fire to the facial hair again. A couple of guys around here may twig to what I am talking about, the profile pic was taken after one of Pam's attacks with the scissors.

Congrats on the new machine, what did you pick up?

If you haven't messed with stick on inverters, just keep in mind that most won't run a 6010, so just go with a 6011 for those applications.

I ran across this ridiculous toy at a pawn shop and had to give it a try:

It's probably smaller than a 50lb box of electrodes. I have no idea what I'll do with it, but I maxed the setting and tried it out using a heavy 100ft extension cord from a crappy generator and it still maintained a decent arc on 3/32 7018 and 1/8 6011. With that setup I think a 3/32 6011 would've been right in the sweet spot.

I currently have two trucks, with most of my tools and the multi-process machine in one, so that little guy rides in the non-work truck.

Anytime I'm welding 14 Guage I try and run it downhill with a 6010/6011 whipping it fastI haven't messed with 6013, but could you run a 1/8" rod cold enough to not burn through 14ga sheet and still gap-weld those seams?

I could do it with wire, but I personally would need a tighter fit or heavier material to try that with a stick unless it was a comically small electrode

I haven't messed with 6013, but could you run a 1/8" rod cold enough to not burn through 14ga sheet and still gap-weld those seams?

I could do it with wire, but I personally would need a tighter fit or heavier material to try that with a stick unless it was a comically small electrode

yes, i think you would be fine. i would run the 1/8 vs the 3/32 because of the heavier angle i would pull and being thicker avoids sticks, takes the whip out of it.

make sure each joint is cool to the touch before starting and you would be surprised.

i used to use hobarts 6013, dont remember the #, but it had pink colored flux. loved it. used it a lot for repair work

@hermosabeach that was quite the entertaining video you put up there. Kinda "captures" the concept. But about that 'soundtrack', did you have "electric-recorder" in your search-engine, or something?

Made this the other morning at work. Took about 5 hours to layout, cut and weld. I highly recommend fireball squares if I haven't already said that in this thread. I bought some about 2 years ago and they are awesome for squaring shit up. I am 1/16" out of square on the project and never once checked for square with a tape until the end of the project.

Does this count as Metalworking?

I handchecker 1911 frame frontstraps. I've always wanted to learn welding.

I handchecker 1911 frame frontstraps. I've always wanted to learn welding.

Congrats on the new machine, what did you pick up?

If you haven't messed with stick on inverters, just keep in mind that most won't run a 6010, so just go with a 6011 for those applications.

I ran across this ridiculous toy at a pawn shop and had to give it a try:

View attachment 7076247

It's probably smaller than a 50lb box of electrodes. I have no idea what I'll do with it, but I maxed the setting and tried it out using a heavy 100ft extension cord from a crappy generator and it still maintained a decent arc on 3/32 7018 and 1/8 6011. With that setup I think a 3/32 6011 would've been right in the sweet spot.

I currently have two trucks, with most of my tools and the multi-process machine in one, so that little guy rides in the non-work truck.

Michigan 140A arc Tig welder.

Similar threads

- Replies

- 0

- Views

- 535

- Replies

- 10

- Views

- 2K

- Replies

- 13

- Views

- 2K

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 330

- Views

- 25K