For the money I liked the HF ones I has. Nothing special and they did the job. Problem was battery was nonreplacable and would die at inopportune moments. I like the jasper that I got to replace the last HF one. It's one of the more economical ones but it does a good job and I'm not using it 40hrs a week.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Welding and Metalworking Thread

- Thread starter bogeybrown

- Start date

Little lathe and welding work this morning....

Making a late model bobcat door fit my Komatsu. I'm doing this with only materials I have at the shop which has added to the challenge. I still have a ton of work to do... I kinda regret not making some 1" square tube dies for the bender and bending the tubing.

any of you fellows have a need or interest in a pc. of 316 stainless steel round stock 6" dia. about 90" long..???

its in NC..

its in NC..

any of you fellows have a need or interest in a pc. of 316 stainless steel round stock 6" dia. about 90" long..???

its in NC..

How much? My friend's machine shop uses that pretty regularly

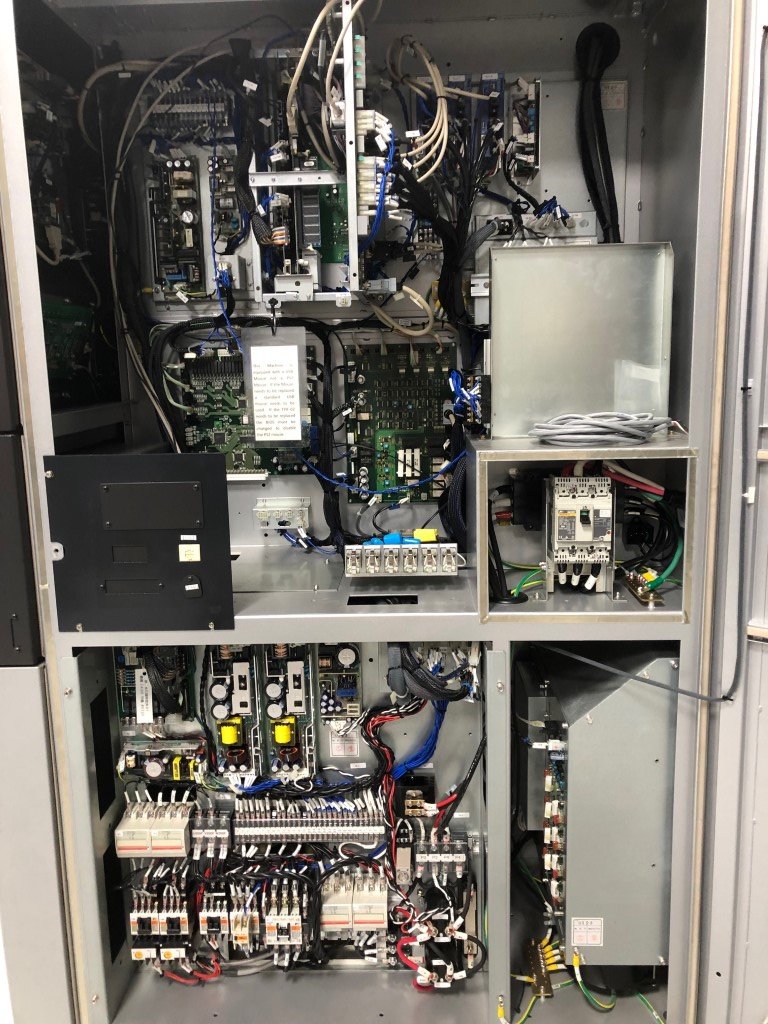

Don't know if I can ever figure out how to use it but figured for $50 at a local tech school auction it was worth a shot. Supposedly not used much. Any EDM folks familiar with this unit?

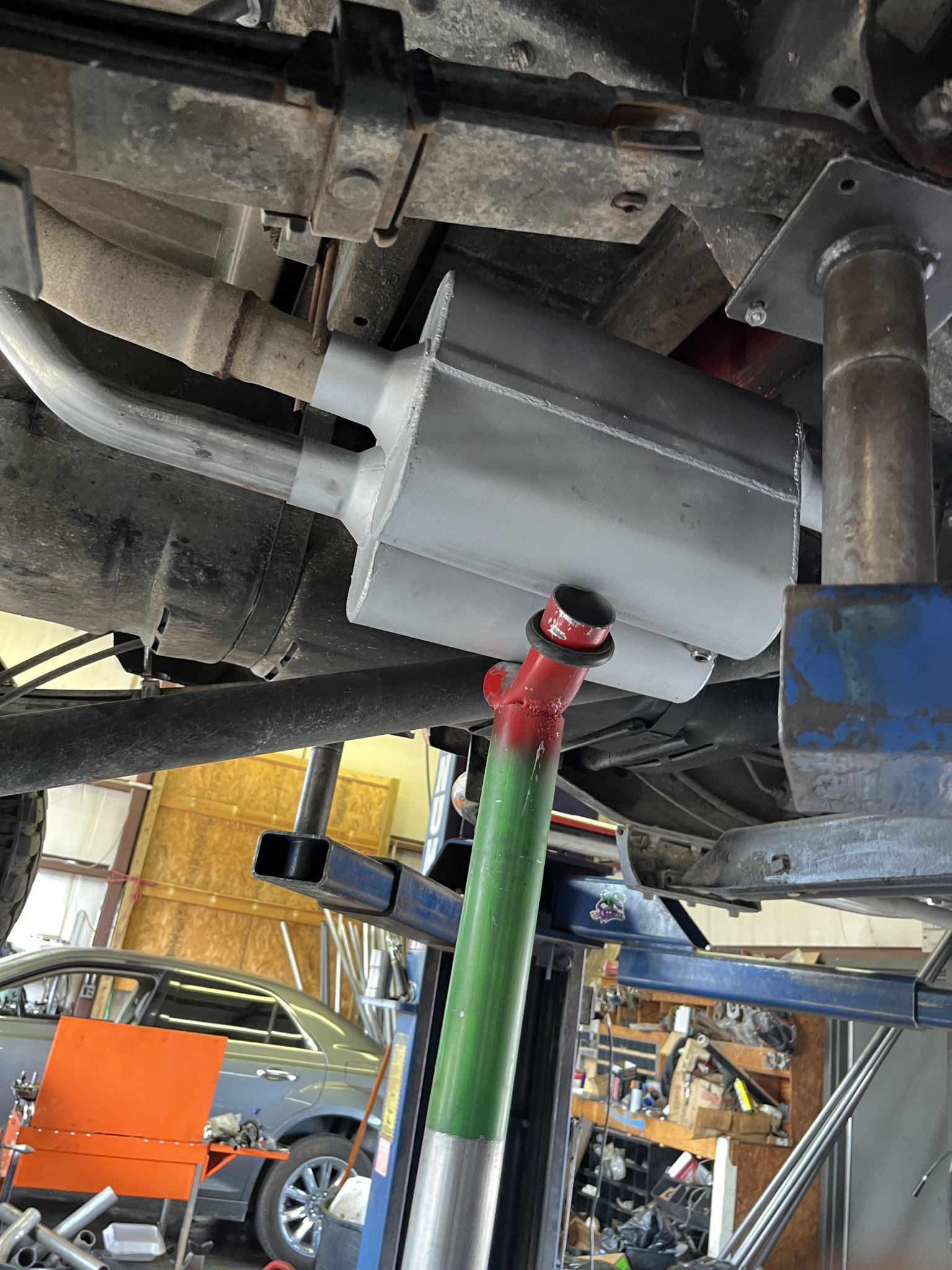

Just helping some, didn’t tackle it all. It is temporary until the exhaust gets all redone, probably coincide with a motor build once this one goes boom

$50 what the hell!Don't know if I can ever figure out how to use it but figured for $50 at a local tech school auction it was worth a shot. Supposedly not used much. Any EDM folks familiar with this unit?

View attachment 7897890

I have run the larger versions of the Sodick. I am more familiar with Charmilles. You have to keep it CLEAN. If that unit uses DI water then the filters and resin have to be kept up with. If that one runs with petroleum based EDM fluid, it is kinda same thing. Must keep clean, keep up with filter changes. I really have wanted a small EDM for my shop.

Many years ago, myself and a buddy built our own EDM for a quick job, and simply used the quill on a drill-press. I have since slowly acquired better things to do a better job on the next go-round.

It truly is/was a simple project, and it worked fantastically. And, fwiw, we used a bath of kerosene. Voltage and arc-spacing is the key controlling factor.

That unit though,,, it has LOTS of buttons. Probably back-door the Pentagon with that thing....

(obviously, technology has far surpassed 'hobby use')

It truly is/was a simple project, and it worked fantastically. And, fwiw, we used a bath of kerosene. Voltage and arc-spacing is the key controlling factor.

That unit though,,, it has LOTS of buttons. Probably back-door the Pentagon with that thing....

(obviously, technology has far surpassed 'hobby use')

Think it's got lots of buttons? Take a look at the innards!

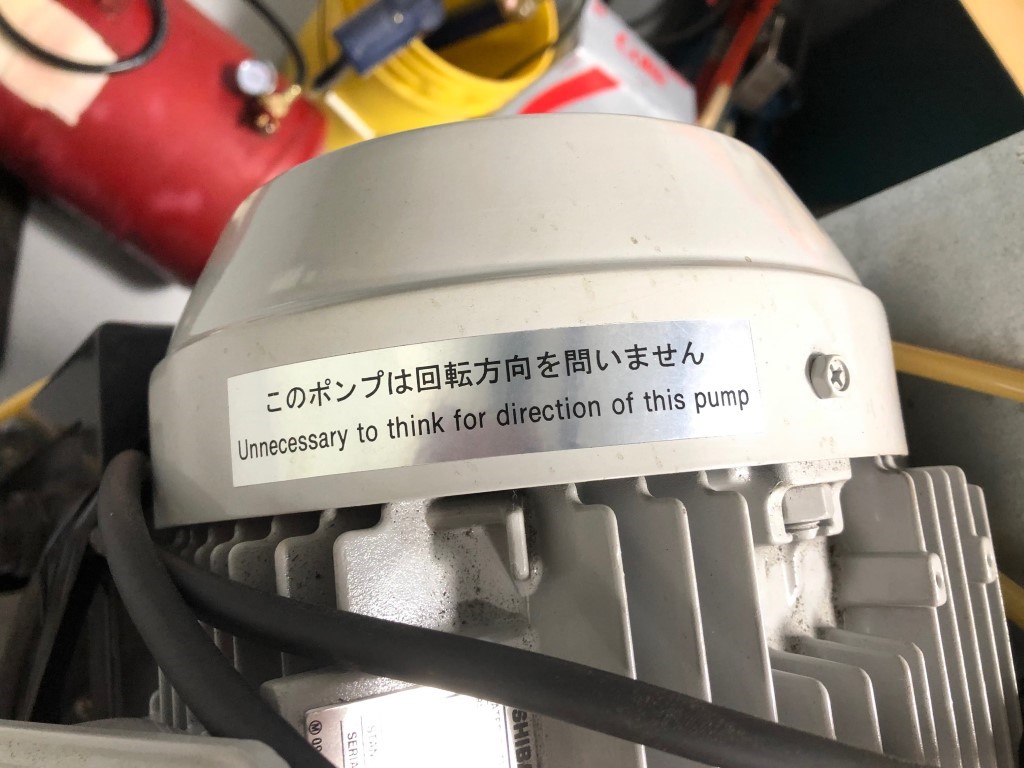

At least I don't have to figure out this pump!

At least I don't have to figure out this pump!

My German shepherd ate my cheap plastic bench block awhile back. He was hanging out with me in the shop while I was working, and apparently he got bored. He swiped it of the workbench without me seeing it.

By the time I realized he had it, it was too late. I was pretty surprised by how much damage he did in so little time.

Anyway

I finally got around to replacing it. Made a set of two. One is delrin, one is steel. I kinda copied the design from the Starrett 119 bench block.

By the time I realized he had it, it was too late. I was pretty surprised by how much damage he did in so little time.

Anyway

I finally got around to replacing it. Made a set of two. One is delrin, one is steel. I kinda copied the design from the Starrett 119 bench block.

Last edited:

Did that come from our plant?Think it's got lots of buttons? Take a look at the innards!

View attachment 7897997

At least I don't have to figure out this pump!

View attachment 7897998

I've got a bunch of Korean motors, and we have 100s of control panels similar to that one.

I finally finished painting my lower body, replaced a headlight and painted my deer-guard so I got it installed. Gonna either do skid plates or rocker guards next (already have all that material)

Attachments

That is pretty standard Wang Chung lingo for "this motor is not polarity sensitive" meaning it will turn the same way even if you do wire it backwards.....like most idiots do.Think it's got lots of buttons? Take a look at the innards!

View attachment 7897997

At least I don't have to figure out this pump!

View attachment 7897998

Nice! That's one thing I like doing, not king-pins, but making tools. My boss is always amazed, he tells me "you could sell those!" Everyone I work with are always asking me to make them something.Quick little project at work since the shop doesn't have a king pin press. It's good to do a little fab work again.

View attachment 7945619

I honestly don't think anyone likes doing king pins......unless you're a helluva masochist.Nice! That's one thing I like doing, not king-pins

I honestly don't think anyone likes doing king pins......unless you're a helluva masochist.

It's a nice change of pace instead of dealing with aftertreatment systems and wiring issues all summer. It would be a different story if I had to beat the pins out or lance them out.

My backhoe kept plugging fuel filters and could not find a good way to get inside the tank for cleaning. Machine is a '99 with 3900 hrs, needless to say I will keep the tank full from now own. Forgot to take a picture of it back together but used a pro mig 140.

Very nice sir. Post the pics when its done. Having to make some of the same on my side over here.Have a fun project at work that is a little different than the ordinary.

Making a 24” long, 4 sided aluminum fixture for a 4th axis in a vertical mill.

Machined all sides of the block, and one end bolts to the rotary platter.

The other end has a support shaft that will be set into a bearing and support structure.

When finished it will have some ficture plates attached on each side for large runs of parts.

Got a ways to go but wanted to share a little of it up to this point.

I have three torches that need to be repaired. I can take them to the local Airgas dudes but results have been less than spectacular in the past. Anyone know of a true refurb shop? My AO is full of shade tree guys that don't know oxygen from acetylene evidently.

Home | Bills Welder Repair - Equipment Repair & Welding Supplies OKC

Over 60 years of welder repair excellence. "Fast, dependable service from a name you can trust." Shop Welding Supplies & Parts from Bills Welder Repair.

www.billswelderrepair.com

www.billswelderrepair.com

Little wood working, metal working and I'm ready for Riot Season!

I like that. Very clean. What bearings did you use on the end? Thinking about chips, coolant, etc.Here it is in the machine this morning.

Testing it for fit and finish before we move on.

View attachment 7946032

Working on a project and have a question: what is the tightest you can bend a piece of 1" tube and still keep a full ID (no pinching)? It will have fluid/air going through it so I want to keep it as streamlined as possible. I have a bender that will do the trick but was wondering how much closer it can be done (and how) other than the circle this will bend at.

Looking at standard schedule 40 steel pipe. Angle would be 180 deg.Lots of variables go into that answer. What material, wall thickness, angle…

Fill it full of sand cap and bend will not collaspeLooking at standard schedule 40 steel pipe. Angle would be 180 deg.

If you are working in a tight area, what about just use a 180 ell ?Working on a project and have a question: what is the tightest you can bend a piece of 1" tube and still keep a full ID (no pinching)? It will have fluid/air going through it so I want to keep it as streamlined as possible. I have a bender that will do the trick but was wondering how much closer it can be done (and how) other than the circle this will bend at.

Mid-States: Carbon Steel Pipe Fitting - Long Radius 180 Return Bends

EMT, Ridgid, gas pipe, round???

A fitting will always be closer than anything you can bend.

Need more specifics...

A fitting will always be closer than anything you can bend.

Need more specifics...

Really does depend on material used.Working on a project and have a question: what is the tightest you can bend a piece of 1" tube and still keep a full ID (no pinching)? It will have fluid/air going through it so I want to keep it as streamlined as possible. I have a bender that will do the trick but was wondering how much closer it can be done (and how) other than the circle this will bend at.

Here's a die chart of capability

Mittler 950 Tube Bender Dies

Tubing bender dies for the Mittler Brothers 950 tubing bender, for bends up to 180 degrees.

For this bender

Mittler Brothers Model 950 Manual Tube Bender

The Mittler Brothers Model 950, 180 degree manual bender is the perfect solution for small tubing applications 1 inch OD and smaller.

a whole other topic of discussion would be the fluid/gas that is being transported into it, and the friction caused therein. In theory, your radius can be 'within itself' if you were to conceptualize a "slinky" and simply fold it back so-as-to have the 1 wall between the two ports.

Yes, it CAN be done.... question is,,,, "should" it be done? So much more depends on your application and intent.

Yes, it CAN be done.... question is,,,, "should" it be done? So much more depends on your application and intent.

22” long fixture plates to go on the 4th axis rotary.

View attachment 7955658

Heavy breathing can be heard all over the interweb.....

YES!! I don’t care if they turn into welders or doctors. If they learn life skills in that class it’s a 100% win. I’m not joking in the least. Working with the hands and brain is potent wampum in life for independence and independent thought.Started setting up another welding lab in another highschool today. No body taught in this space since before covid. Long way to go but it will be somthing eventually.

Before and after

I try to beat them with the stick of critical thinking as often as possible. Kids are knuckle heads but they tell me on occasion that welding class was the only reason they came to school today.

Last year two kids skipped the whole day to hunt ducks but came to school last block for welding class. I thought it was hilarious but administration did not.

Last year two kids skipped the whole day to hunt ducks but came to school last block for welding class. I thought it was hilarious but administration did not.

Sounds like like the admins need to pull the stick out of their ass and maybe even go duck hunting. They might find that their students have more regard for them and then decide to come to school to be around adults who regard them as something more than numbers. I had a math teacher who taught me to bow hunt, another was a fishing maniac. We got along great and I looked up to them. As an adult we stayed in touch and they still influence my life in positive ways.I try to beat them with the stick of critical thinking as often as possible. Kids are knuckle heads but they tell me on occasion that welding class was the only reason they came to school today.

Last year two kids skipped the whole day to hunt ducks but came to school last block for welding class. I thought it was hilarious but administration did not.

Last edited:

Metals shop was my favorite class in high school!Started setting up another welding lab in another highschool today. No body taught in this space since before covid. Long way to go but it will be somthing eventually.

Before and after

Mentors; seek them out, then be one...Sounds like like the admins need to pull the stick out of their ass and maybe even go duck hunting. They might find that their students have more regard for them and then decide to come to school to be around adults who regard them as something more than numbers. I had a math teacher who taught me to bow hunt, another was a fishing maniac. We got along great and I looked up to them. As an adult we stayed in touch and they still influence my life in positive ways.

Good words spoken. A book that should be on the reading list of every HS student is "ShopCraft as SoulCraft" which the author talks about the intrinsic value of working with your hands. Always worked with tools since I was a kid and put myself through college workings as a welder on a large ranch and in the oil fields of northwest NM. The life skills I learned working those jobs helped me immensely in my professional career. Still working full-time as a PM but nearly every evening after work and on the weekends you will find me in the shop either welding, woodworking or tinkering with machinery. It is something I look forward to every day.YES!! I don’t care if they turn into welders or doctors. If they learn life skills in that class it’s a 100% win. I’m not joking in the least. Working with the hands and brain is potent wampum in life for independence and independent thought.

I left the ranch thinking I would find fortune in other endeavors. What I found was something else entirely. And God lead me back to where I am now. I won’t say it is easier by any stretch, but instead of false pride I have found self respect. That’s worth everything. It all started with work and the critical thinking skills you mentioned. Now I train my employees in critical thinking more than I train them on the trade. And they do better with that than anything. My best days are when they question me, even if they don’t get it totally correct. The absolute best days are when they come up with a better way or show me that I am wrong. I tell my guys that I don’t fire people for being wrong, I fire for not caring. When they are able to tell me they screwed up or have a problem but come to me with a solution (this is mandatory once they have enough experience) then I know they are on the right path in life. Those teachers I mentioned and God showed me that. Grace and leadership are important to give and pass on. Not that I get it right all the time but I do try.Good words spoken. A book that should be on the reading list of every HS student is "ShopCraft as SoulCraft" which the author talks about the intrinsic value of working with your hands. Always worked with tools since I was a kid and put myself through college workings as a welder on a large ranch and in the oil fields of northwest NM. The life skills I learned working those jobs helped me immensely in my professional career. Still working full-time as a PM but nearly every evening after work and on the weekends you will find me in the shop either welding, woodworking or tinkering with machinery. It is something I look forward to every day.

I’ve been absent for a long while largely because I’ve been working like a lunatic all over the country.

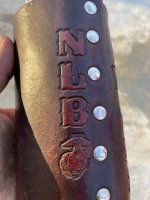

My work partner up here in Madison, WI is a badass Ironworker and does custom leather work. I had him make me the above rod holder.

I had to get a pic of it in good shape because I instantly started abusing it

My work partner up here in Madison, WI is a badass Ironworker and does custom leather work. I had him make me the above rod holder.

I had to get a pic of it in good shape because I instantly started abusing it

10" sch.160 2¼ chrome. Tig all the way. Started on it about 8:30am, hope to be done by 3:30 this afternoon. Maybe 4:00. Heating pads for preheat/stress relief so it's smoking hot for about 3' in each direction. Glad it's kind of cool today.

Running a Lincoln vantage they only go 257 amps on touch start so it's kind of slow going. Thought about switching it to stick to jump up to about 300 but I like touch start too much. Burning 5/32 90s filler metal.

We were allowed to "Bridge Tack" but nothing outside the bevel was allowed.View attachment 7987227

View attachment 7987228

10" sch.160 2¼ chrome. Tig all the way. Started on it about 8:30am, hope to be done by 3:30 this afternoon. Maybe 4:00. Heating pads for preheat/stress relief so it's smoking hot for about 3' in each direction. Glad it's kind of cool today.

Running a Lincoln vantage they only go 257 amps on touch start so it's kind of slow going. Thought about switching it to stick to jump up to about 300 but I like touch start too much. Burning 5/32 90s filler metal.

Refinery or power house?

Similar threads

- Replies

- 0

- Views

- 533

- Replies

- 10

- Views

- 2K

- Replies

- 13

- Views

- 2K

Precision Rifle Gear

Tango Innovations FIRE4000 WMLRF Initial Impressions

- Replies

- 330

- Views

- 25K