all i could do was sit and cry ... and buy my ammo online . felt like the indian in that commercial one lone tear running down his face looking out over a land scape covered with trash , thinking about all the ammo I could be making per day if only the land lord cared ... crates floor to ceiling stacked pretty like trees in a forest of ammo to shoot lol i fell into that one .

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

Loaded up 35 6mm creedmoor. Still have 47 to fire form brass. I will get out do it next weekend.

Are those chargemaster pretty accurate?

I hope they are. They say + or - 0.1 grain accuracy.

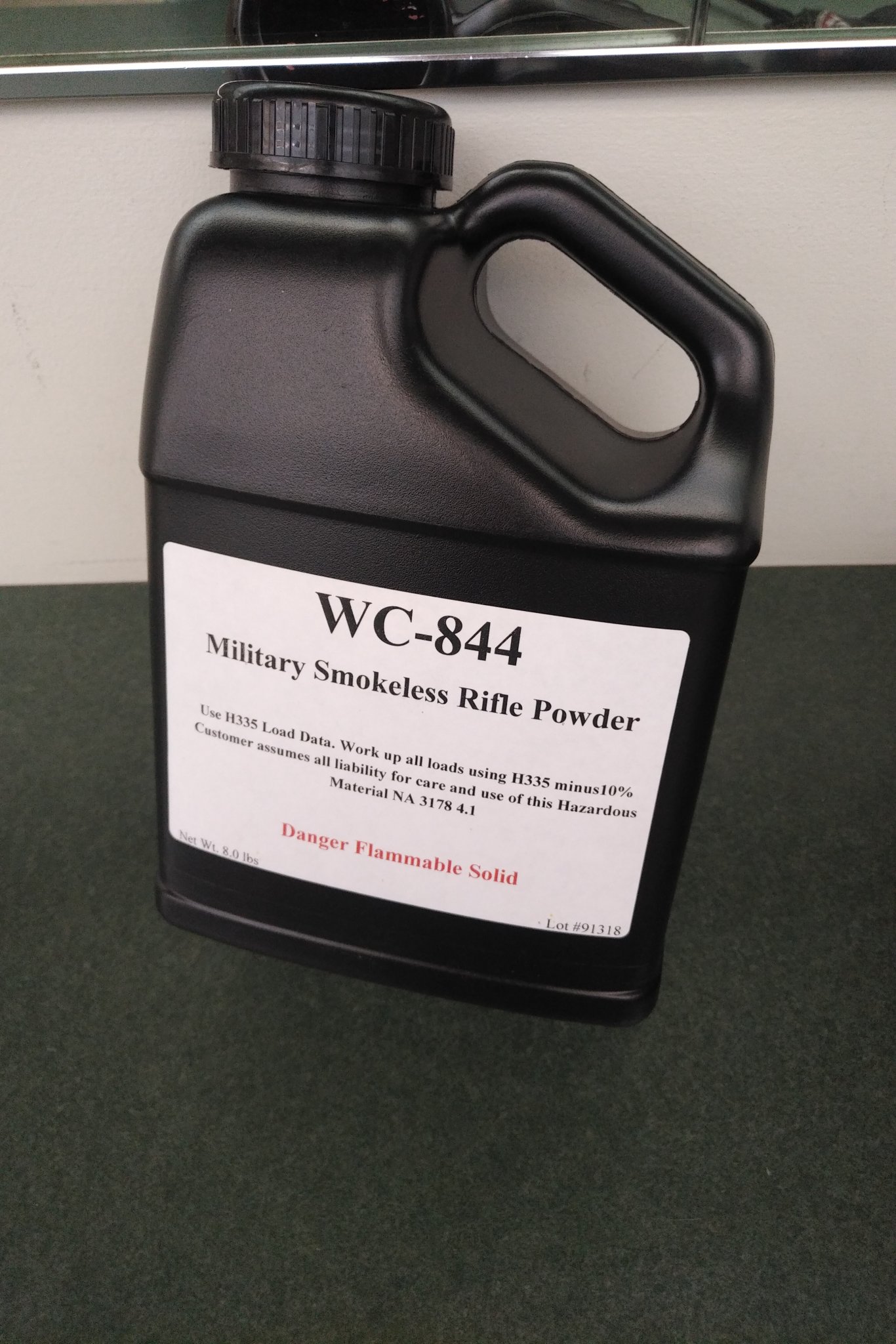

Got 200 pieces of 5.56 LC brass sized and trimmed this PM. So now I have 700 pieces ready to go. Just waiting for a shipment of powder and primers to come in.

For those who use the Chargemaster, what powder type do you guys use? I'm talking ball, flake or extruded?

I use my Redding Model 3BR powder measure for all my 5.56 and 300 Blackout loads. When I get 5 good throws in a row, then I'll start throwing 10 and check one and repeat until done. I do pistol calibers like this too if I'm loading up a small amount, like 20 rounds for testing, that is unless the Dillon is already set up.

I use my Redding Model 3BR powder measure for all my 5.56 and 300 Blackout loads. When I get 5 good throws in a row, then I'll start throwing 10 and check one and repeat until done. I do pistol calibers like this too if I'm loading up a small amount, like 20 rounds for testing, that is unless the Dillon is already set up.

Chamfer and deburr some 223 casesView attachment 7112569

Chamfering and deburring is the worst......

It's not too bad with this.Chamfering and deburring is the worst......

Damn it, sharpie residue? Will it mess it up noticeably over the course of 100 rounds?

Ive never bothered with marking cases before so this is my first sharpie experience because I didnt necessarily mind losing a piece here and there before. Now that Im onto a dasher I get the jokes and want to horde all of my precious.

I've found a paint pen around the extractor groove works well.

Attachments

Man who you tellin. I just got finished with about 1k and finally ready to load them up. Hopefully wont have to do that for a while. Lol. Got about another 2-3k 223 brass sitting in the attic ready to prepped.Chamfering and deburring is the worst......

Man who you tellin. I just got finished with about 1k and finally ready to load them up. Hopefully wont have to do that for a while. Lol. Got about another 2-3k 223 brass sitting in the attic ready to prepped.

I have that lyman case prep center and the forster trimmer. Just picked up the 3in1 head for the forster and it eliminates the D&C as an additional step.

Sized, tumbled, chamfer'd, deburr'd 100 6.5CR casings for final load up. Also, Prepping for a mess of 5.56 62gr loading ???

Chamfer and deburr 223??Chamfer and deburr some 223 casesView attachment 7112569

Not me! I couldn't imagine doing that for all the 223 I go through in my AR! LOL

Deprime, tumble, size, trim, prime, load, crimp.

Only my precision brass (6.5CR, 7mm RemMag) get the extra love.

Chamfer and deburr 223??

Not me! I couldn't imagine doing that for all the 223 I go through in my AR! LOL

Deprime, tumble, size, trim, prime, load, crimp.

Only my precision brass (6.5CR, 7mm RemMag) get the extra love.

Lol, for the AR I don't even bother trimming. It goes straight to the progressive for production.

Chamfer and deburr 223??

Not me! I couldn't imagine doing that for all the 223 I go through in my AR! LOL

Deprime, tumble, size, trim, prime, load, crimp.

Only my precision brass (6.5CR, 7mm RemMag) get the extra love.

I was doing chamfer/debur on .223 but I'm thinking this next go round, with the addition of a 21st Century neck size die, I'm just going to let the stainless steel dong do its work.

Still thinking the bolt guns in .308 and 30-06 need that love though.

I have that lyman case prep center and the forster trimmer. Just picked up the 3in1 head for the forster and it eliminates the D&C as an additional step.

I C&D with the three head Hornady Case Prep tool. It's a horizontal operation rather than vertical has a primer pocket scraper for the third operation.

Works but tedious.

Nothing wrong with fondling some.......brass.

Well,,,,,, I’m gonna have to tumble the brass clean now.

Things got a bit outta control.

Sometimes that happens when fondling things. But remember, after fondling the outcomes is usually pretty good.Well,,,,,, I’m gonna have to tumble the brass clean now.

Things got a bit outta control.

Loaded up some 223 test rounds last night...waiting for the magnetospeed to come in...hopefully by this weekend i can get some data.

Figure out how to set it up and then get to work on some 6.5cm

Figure out how to set it up and then get to work on some 6.5cm

I have ADG 7mm RemMag brass. Very very good stuff. Weights are within 3-4 grains of the average.

I was doing chamfer/debur on .223 but I'm thinking this next go round, with the addition of a 21st Century neck size die, I'm just going to let the stainless steel dong do its work.

Still thinking the bolt guns in .308 and 30-06 need that love though.

Its not really about love. Its about getting the bullet seated without tearing up the bearing surface. Trimming leaves a burr, seating past that burr shaves copper off the bullet. In my experience not chamfering deep enough causes copper to get shaved off bullets too. If you dont want to deburr and chamfer, you should probably use an M die to bell the case mouth, then crimp it back. This is common practice making handgun ammo. I only chamfer and debur after trimming. I only trim when the brass gets too long.

I took the brass out of the tumbler that I forgot overnight. Ten hours makes for super shiney brass.

It still doesn't clean the primer pockets.

It still doesn't clean the primer pockets.

A cutoff timer for the tumbler power is a good investment to get a longer life out of it.

Lol, for the AR I don't even bother trimming. It goes straight to the progressive for production.

Same here. Just primed 500 Lake City .556 cases. The only case prep I did was to iron out banged up case mouths. I simply run the case over the expander ball on the stem I removed from my die on those I thought needed it. The expander ball assembly is in a vise. Takes about 1 second or two per dinged up case.

Add a new top to one section of the reloading bench. I like this much better.

Lost my comparator set and Mitutoyo caliper kit... I suspect the wife.

Lost my comparator set and Mitutoyo caliper kit... I suspect the wife.

My wife wouldn't even know what to do with a caliper, let alone a comparator.

My wife wouldn't even know what to do with a caliper, let alone a comparator.

Probably looking for an accurate measurement of length and girth because her friends think she can't be telling the truth.

Funny she left the 6 inch caliper and only took the 3 inch.

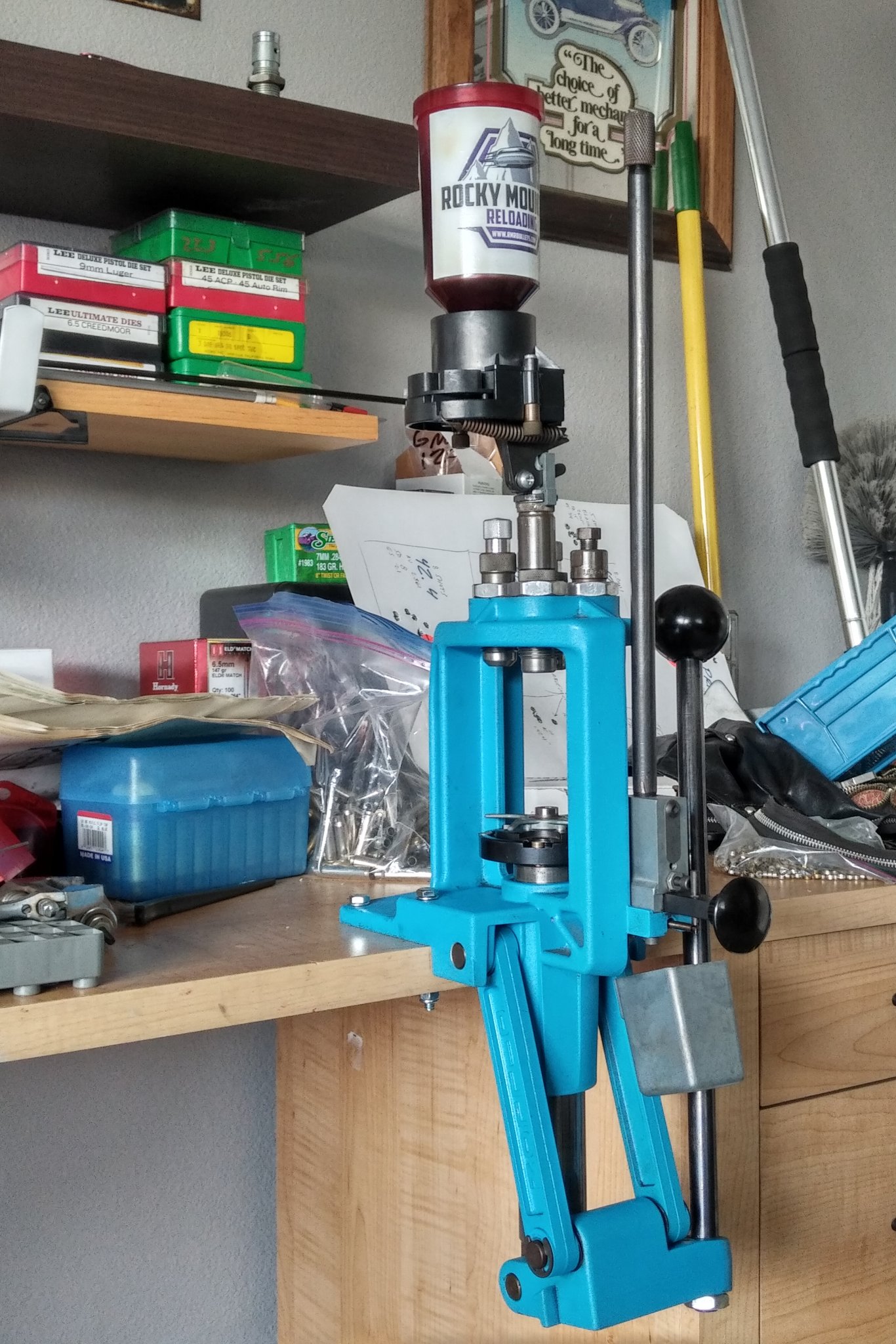

Mouted up my new-to-me Dillon RL450 I got off FleaBay. More shell plates, locator buttons, and Dillon auto powder measure on the way from Dillon in AZ as we speak.

Loaded 10 of my old 6xc brass to see how they fit in my new barrel when I put it on tomorrow to see if I will need new brass or not.

Loaded 10 of my old 6xc brass to see how they fit in my new barrel when I put it on tomorrow to see if I will need new brass or not.

Smash em down in a small die until they fit! Ride that brass into the ground until the primer pockets are gasping for air.

Amen!Smash em down in a small die until they fit! Ride that brass into the ground until the primer pockets are gasping for air.

I’m just worried about the base diameter, first barrel was a new reamer, new barrels old old reamer etc. might buy that pva base sizing die. I was really hoping that Peterson would have the new select cases or whatever where they weight sort them in batches but they say 6xc is in the docket for October. And October’s the start of hunting which is later than ideal, hopefully old brass will tide me over.Smash em down in a small die until they fit! Ride that brass into the ground until the primer pockets are gasping for air.

I’m just worried about the base diameter, first barrel was a new reamer, new barrels old old reamer etc. might buy that pva base sizing die. I was really hoping that Peterson would have the new select cases or whatever where they weight sort them in batches but they say 6xc is in the docket for October. And October’s the start of hunting which is later than ideal, hopefully old brass will tide me over.

I've been messing with Dasher brass between two barrels, one big and one small chamber for base dia. I found that a standard Hornady 308 die did a pretty darn good job of sizing the base down, took it to around .4695 where a Harrels D4 (supposedly tighter base) would only hit around .4702. Had a to bump the shoulder back since everything got pushed forward. But overall was able to have brass fit into the smaller chamber once it was done. Primer pockets are still good so didn't want to toss the brass.

Shot a club match with the brass in the small base Dasher chamber, took 2nd. Then processed it all and shot the CO NRL match with the same brass in the larger chamber and took 3rd there. 15 firings and still going strong!

I've been messing with Dasher brass between two barrels, one big and one small chamber for base dia. I found that a standard Hornady 308 die did a pretty darn good job of sizing the base down, took it to around .4695 where a Harrels D4 (supposedly tighter base) would only hit around .4702. Had a to bump the shoulder back since everything got pushed forward. But overall was able to have brass fit into the smaller chamber once it was done. Primer pockets are still good so didn't want to toss the brass.

Shot a club match with the brass in the small base Dasher chamber, took 2nd. Then processed it all and shot the CO NRL match with the same brass in the larger chamber and took 3rd there. 15 firings and still going strong!

Thanks for the info regarding the Hornady 308 die. My 6 Dasher Lapua ,twice fired, measures .4695" just above the extractor groove so it looks as though the Hornady die will do just fine resizing the base.

LOLLLL yeah I got Lee dies on my Dillon. Ghetto fabulous

Similar threads

- Replies

- 14

- Views

- 810