Just started with a 6GT. All my previous 6mm's were .243s.

26" 7.5 twist Bartlein 5R HV

Tikka factory action and trigger

AICS 10 round steel mags (all fed smoothly)

KRG X-Ray chassis

Burris XTR II 8-40X-50

Vortex matched rings

EGW base

Area 419 Hellfire brake (not used for this testing)

Virgin Hornady brass 'mandrel sized' using just the expander stem in a Lee .243 Win. collet die (yes, I'm that cheap), and seating done with a Whidden micrometer die (but not *that* cheap

. I was pleasantly surprised by the Hornady brass. All 100 pieces were within 1.5 grains of each other (136 grain avg.), the untrimmed cases were 1.718 ±.002, and unsized headspacing was 1.353 ±.0005 (1x fired cases are showing 1.354 ±.0005 headspace and still ~1.718 trim length).

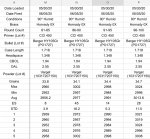

Used light (33.0 and 32.0 grains) of N140--fairly clean burning and close to Varget--behind some leftover 90 grain Nosler BTs and 95 grain Hornady SSTs for barrel break-in and rough 100-200 yard sight-in. Then used 37.0 and 37.5 of H4350 and 35.0, 35.5, and 36.0 grains of VV N150 behind 105 RDFs for 200 yard testing. All loads used CCI 450 primers.

I couldn't find any data on N150 for the GT, but knew it is closer to H4350 than it is to N140 and Varget in terms of burn rate. Still, even 35.0 is a bit too hot. No ejector marks, even at 36.0, but slightly stiff bolt lift on all and some light burnishing on the headstamps of a few. Flattened, but not cratered, primers. I have since done a face palm and looked at the VV N150 data for 6 Creedmoor, which tops out at 34.9 for the Hybrid Target and 35.8 for the VLD Target. D'OH! That's why it is called a *relative* burn rate chart.

Initial COAL/CBTO was determined by decreasing the seating on an empty case until I could gently, VERY gently, close the bolt, then seating ~.025 more (tested and inspected all loaded rounds to ensure no marking on the bullets). This worked out to:

2.450/1.962 Nosler 90 BT

2.405/1.930 Hornady 95 SST

2.540/1.960 Nosler 105 RDF

The target image is 200 yard testing of the H4350 and N150 loads (slight 3-5 mph head wind, ~90 degrees F, 80% relative humidity, near sea level, using a bipod and rear bag on a bench). Odd, but not unexpected, flyers with H4350 (due to the rough sizing/seating, not the powder, I'm sure), but okay results. N150 did a little better, but still a lot of room for improvement for both.

All should improve with 1x fired and properly sized cases, and some chronographing. If so, great. If not, then will be testing with N140, Varget, and Reloder-16. I have now drilled and tapped a fired case for my OAL gauge, and look forward to some proper seating depth testing. I also have a Whidden FL bushing sizing die and can test neck tension if needed, but I'm doing plenty of "foolish wand waving and silly incantations" to avoid having to turn case necks

. I'd like to stick with the 105 RDFs if I can since they shoot great in my .243s and I have a LOT of them, but I also have some 108 ELD-Ms and some 115 RDFs. Will update ASAP.