Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Range Report 6GT Project/Range Report

- Thread starter NorCal Vu

- Start date

About to order my first gt barrel switching over from 6.5 creed. Cant decide whether to go with 105 hybrids or 115 dtacs? Haven't seen to much about the dtacs on here has anyone had luck pushing a 115? I have seen a bunch of posts about the 112 match burners so probably not much different, but curious anyways. I shot 123's out of my 6.5 at 3050 so the thought of shooting 115's at maybe 2950 seems slow and I know it will be less recoil but will it make that much difference? For what it is worth I have been shooting the 6.5 with a bare muzzle and the new barrel will have a gen 3 little bastard so I am already gaining there. If I go light and fast again how much barrel life am I losing? Thanks for any help!

I've been shooting Berger 105's at 3040ish and Hornady 110 A-tips around 2995ish and both have shot great. just grabbed some Berger 109 hybrids and expect them to be very similar.

I've searched a couple times but can't seem to find it, what is the case trim length for the GT?

I've searched a couple times but can't seem to find it, what is the case trim length for the GT?

I haven’t trimmed any yet, but virgin Hornady is 1.715 ?

What is everyone using for a bore guide when cleaning?

I just have a cheap plastic one I got from either cabelas or Amazon. Don’t need some expensive one. Any decent one will work

I started with Dtac's but moved to 109's because I was having constant fliers. I know my bullets are good as they shoot fine in my creedmoor. I'll revisit them when the weather is warmer just in case it's a cold weather stability issue... I'm using a 7.5 twist so that shouldn't be an issue. Don't I've seen stranger things happen.

In that diagram it looks like 1.746 from the case mouth to the flash hole but doesn't give a measurement from there to the case head. I use the lee case length gauge trimmers so I will have to order a custom one for 6gt since they don't offer it yet.

In that diagram it looks like 1.746 from the case mouth to the flash hole but doesn't give a measurement from there to the case head. I use the lee case length gauge trimmers so I will have to order a custom one for 6gt since they don't offer it yet.

those measurements are from the bolt face not the flash hole...im pretty sure you need to be looking at the 1.732 im pretty sure thats the neck length of the reamer

And typical specs on saami prints dictate up to .020 under is fine so 1.732-.020 meaning a proper trim length is from 1.712-1.732

Just finished measuring my gt barrel. Going to just load 34.0gr of varget for the first 100-200 rnds until it speeds up.

I will say, it feeds incredibly smooth in my AT. My dasher feed well, but I could always “feel” it if that makes sense. This barely feels like a round is there.

I will say, it feeds incredibly smooth in my AT. My dasher feed well, but I could always “feel” it if that makes sense. This barely feels like a round is there.

Breaking in the brand new Benchmark barrel from Straight Jacket Armory with a quick little barrel stage practice. 5 shots within 45 seconds, paper target at 100.

@NorCal Vu Count yet another barrel that likes 33.5gr Varget under a 105 Hybrid seated in new Hornady brass for .020" off the lands, primer is CCI 450...

@NorCal Vu Count yet another barrel that likes 33.5gr Varget under a 105 Hybrid seated in new Hornady brass for .020" off the lands, primer is CCI 450...

Another data point for folks.

Rifle is a 7.5 twist Benchmark at 24 inches. Currently 425 rounds on the barrel.

115 RDF

450 primer

Hornady brass

My initial goal was to throw charges, but I do not want to be at the top end of the pressure range. I put 150 rounds through the barrel using MR200PP. I stopped at 2900 fps with the 115s. Results were not great ao I quit. May have been different if I went up in the powder charge, but I did not.

The following pics are all RE16.

I ended up at 37.6 grains and 2885.

115 RDF with .040 jump.

Note: I have 2 pieces of brass with 40 firings on them. They still have good primer seartng pressure. They were annealed every 5 to 6 loadings and trimmed 3 times...

Picture of the ladder, it was 40 degrees and these were single rounds at 360 yrda.

Second picture is 685 yards. 2 inch black

3rd is 1015 yrds. That is 8 of the 10. The other 2 were 1 hole at 100 to confirm zero.

4th is a 20 round string for reference.

Rifle is a 7.5 twist Benchmark at 24 inches. Currently 425 rounds on the barrel.

115 RDF

450 primer

Hornady brass

My initial goal was to throw charges, but I do not want to be at the top end of the pressure range. I put 150 rounds through the barrel using MR200PP. I stopped at 2900 fps with the 115s. Results were not great ao I quit. May have been different if I went up in the powder charge, but I did not.

The following pics are all RE16.

I ended up at 37.6 grains and 2885.

115 RDF with .040 jump.

Note: I have 2 pieces of brass with 40 firings on them. They still have good primer seartng pressure. They were annealed every 5 to 6 loadings and trimmed 3 times...

Picture of the ladder, it was 40 degrees and these were single rounds at 360 yrda.

Second picture is 685 yards. 2 inch black

3rd is 1015 yrds. That is 8 of the 10. The other 2 were 1 hole at 100 to confirm zero.

4th is a 20 round string for reference.

Attachments

Last edited:

Because Varget at speeds north of 3000 fps is basically going to mirror the 6 Creedmoor in terms of barrel life.. possibly worse since varget eats throats pretty bad. Could be fine at one of the lower nodes.

You can't get enough H4350 in a case to hit pressure, 100% case fill, slower burning, etc... we'll see, I'm starting with H4350 and 109's or 112's

Can you provide some actual proof that varget (or any other powder) eats throats faster?

I see these claims about *insert powder name* and have never seen any proof provided.

By all means. Shoot a couple of barrels out in the same cartridge with different powders and let us know.

I can tell you Dasher throats erode slower using 4350 than they do using Varget

A couple barrels isn’t proof or anything statistically significant.

Okay. It's your barrel. Do what you want

Which is why I am asking for anything other than anecdotal.

Can you provide some actual proof that varget (or any other powder) eats throats faster?

I see these claims about *insert powder name* and have never seen any proof provided.

As in 2 barrels from the same lot, same chamber reamer and an A vs. B powder comparison, shot at the same pressure and measuring throat erosion.. no. But I've shot out 4 dasher barrels and the throat erosion is a lot with varget.. everytime.

I'm not sure it can all be blamed on varget.. the dasher is usually run at pretty high pressure and the neck length of the case doesn't do it any favors either.

I've got a BRA with about 1k rounds on it now after the TPRC PRS match.. I plan on measuring erosion and comparing it to some previous dasher barrels. Running varget as well. I'm curious if the longer neck lends any benefits.

As in 2 barrels from the same lot, same chamber reamer and an A vs. B powder comparison, shot at the same pressure and measuring throat erosion.. no. But I've shot out 4 dasher barrels and the throat erosion is a lot with varget.. everytime.

I'm not sure it can all be blamed on varget.. the dasher is usually run at pretty high pressure and the neck length of the case doesn't do it any favors either.

I've got a BRA with about 1k rounds on it now after the TPRC PRS match.. I plan on measuring erosion and comparing it to some previous dasher barrels. Running varget as well. I'm curious if the longer neck lends any benefits.

How many more rounds did you get with non varget barrels vs varget barrels before velocity took the first drop?

How many more rounds did you get with non varget barrels vs varget barrels before velocity took the first drop?

I've ran varget exclusively in all of them.

I've got a BRA with about 1k rounds on it now after the TPRC PRS match.. I plan on measuring erosion and comparing it to some previous dasher barrels. Running varget as well. I'm curious if the longer neck lends any benefits.

In the last coule barrels I've been tracking the BRA is slower eroding at the throat than the Dasher, by maybe 30% at equal round count.

Which is why I am asking for anything other than anecdotal.

Start with a burn rate chart. Varget burns faster and hotter than 4350, heat and pressure eat the throat.

Remember when guys were trying to stuff H1000 in a 6 Creedmoor case? Because it burns slower and cooler.

It was an attempt to get better mileage out of the big 6s. A good idea but the speed wasn't really there.

The speed, IMO, is the problem. 3150 is going to torch a barrel in about 800-1200rds.

Slow it down a bit and you get better mileage. My 6x47L has been running at 2950 just about the entire time with the exception of break in rounds before speed leveled off.

It's got 1400 on it and still going strong. The ?️? ? is based on a 6x47 case but that tenth of an inch in length and few degrees of shoulder angle... THAT'S the recipe for success ?

If it's successful it'll be because it's not pushing 3200fps, not because of a few degrees here and a tenth of an inch there.

Start with a burn rate chart. Varget burns faster and hotter than 4350, heat and pressure eat the throat.

Remember when guys were trying to stuff H1000 in a 6 Creedmoor case? Because it burns slower and cooler.

It was an attempt to get better mileage out of the big 6s. A good idea but the speed wasn't really there.

The speed, IMO, is the problem. 3150 is going to torch a barrel in about 800-1200rds.

Slow it down a bit and you get better mileage. My 6x47L has been running at 2950 just about the entire time with the exception of break in rounds before speed leveled off.

It's got 1400 on it and still going strong. The ?️? ? is based on a 6x47 case but that tenth of an inch in length and few degrees of shoulder angle... THAT'S the recipe for success ?

If it's successful it'll be because it's not pushing 3200fps, not because of a few degrees here and a tenth of an inch there.

This again, is more anecdotal than factual as far as the varget vs 4350.

While yes, varget burns hotter and faster, as far as I know, there is no concrete data that says “at the same conditions (speed, cleaning, etc etc) h4350 will on average prolong barrel life *insert percentage* more than varget.”

I do agree speed is a big factor. (What I’m about to say is absolutely anecdotal)

For example, my dasher going 2950 with varget I can run 10-20 rnds somewhere and the barrel is barrel luke warm. My 6cm with 4350 running 3050-3100 is too hot to touch after 5-10rnds.

My 6gt seems pretty close to dasher temperature at 2900 so far. Again, this is just a simple observation that is almost no facts and doesn’t prove anything.

My biggest point in asking was that most everyone has an opinion on what powders do to a barrel and no one has any real facts or data to back up what isn’t even a proper hypothesis.

While yes, varget burns hotter and faster, as far as I know, there is no concrete data that says “at the same conditions (speed, cleaning, etc etc) h4350 will on average prolong barrel life *insert percentage* more than varget.”

You agree heat and pressure eat a barrel, you agree Varget burns hotter and faster than 4350... but you don't agree it'll eat a throat faster? ??

Of course your Creedmoor is going to be hotter, faster. How much MORE powder are you using to push the bullet 150+ fps faster than your Dasher?

Fire 20 rounds from your Dasher and use a laser thermometer to get a temp reading just in front of the action, halfway down the barrel, and the muzzle.

Post up your load and somebody can run it through quickload for an approximate pressure measurement.

Then download your Creedmoor and repeat the test with the Creedmoor running the same pressure.

Of COURSE it's going to be hotter when it's being pushed harder man, comon'.

There is an interesting interplay between a powder's "heat" (referenced as heat of explosion / potential kJ/kg in Quickload), the speed on a burn rate chart, and the resulting pressure/speed in any given case.

Take H4350 for example. It's actually very difficult to hit 60k PSI with a small quantity of powder. By the time you have a small enough case to constrain the powder and generate pressure you've run out of room in the case. You really need a case something like a 6GT or bigger and maybe 37gr of H4350 or more to make 60k PSI.

So you can never really compare Varget against H4350 on equal footing. Can't do same quantity of powder, since you'll never make pressure with H4350. Can't do same velocity since the H4350 will be running at a lower pressure regardless of case used. And if you say equalize pressure so both are at 60k PSI the H4350 load is going to be running much more powder and much higher velocity.

So while the H4350 may have less heat per unit of weight (kJ/kg) in most situations you will be using more total powder offsetting that advantage.

Quickload says H4350 is 3760 kJ/kg and Varget is 4050 kJ/Kg, (energy/heat to weight ratio). That's a roughly 8% advantage. If you use 8% more H4350 than Varget you'll never make pressure with H4350, you'll just have a nice conservative load with less velocity.

Take H4350 for example. It's actually very difficult to hit 60k PSI with a small quantity of powder. By the time you have a small enough case to constrain the powder and generate pressure you've run out of room in the case. You really need a case something like a 6GT or bigger and maybe 37gr of H4350 or more to make 60k PSI.

So you can never really compare Varget against H4350 on equal footing. Can't do same quantity of powder, since you'll never make pressure with H4350. Can't do same velocity since the H4350 will be running at a lower pressure regardless of case used. And if you say equalize pressure so both are at 60k PSI the H4350 load is going to be running much more powder and much higher velocity.

So while the H4350 may have less heat per unit of weight (kJ/kg) in most situations you will be using more total powder offsetting that advantage.

Quickload says H4350 is 3760 kJ/kg and Varget is 4050 kJ/Kg, (energy/heat to weight ratio). That's a roughly 8% advantage. If you use 8% more H4350 than Varget you'll never make pressure with H4350, you'll just have a nice conservative load with less velocity.

Thanks for the info @Sheldon N

On a slightly frustrating side note. My RCBS die will not size any of my cases.

On a slightly frustrating side note. My RCBS die will not size any of my cases.

Could you elaborate about the issues you are having resizing 6GT cases. I want to rebarrel a shot out 65CM with a GT, I'm getting reloading bits together a little at a time, so should I stay away from RCBS dies? They are generally pretty good.

Could you elaborate about the issues you are having resizing 6GT cases. I want to rebarrel a shot out 65CM with a GT, I'm getting reloading bits together a little at a time, so should I stay away from RCBS dies? They are generally pretty good.

I wish I knew more. Tonight was my first attempt at shooting once fired brass. I haven't eliminated the dies or the press.

Thanks for the info @Sheldon N

On a slightly frustrating side note. My RCBS die will not size any of my cases.

This is common and not exclusive to RCBS. I've had to trim 2 different Redding FL sizer dies.

Your chamber is probably cut to min headspace +.002" and the die is punched out "deeper". Trimming the base of the die will solve your problem and allow the die to bump the shoulder.

Call your smith; this likely isn't the first time he's had to do this for a customer. Or, send back to manufacturer.

Grind or sand some material off the top of the shell holder, easier than removing marerial from the die. I had to do it to my 6GT die to bump the shoulder enough.I wish I knew more. Tonight was my first attempt at shooting once fired brass. I haven't eliminated the dies or the press.

How much water will your fired GT cases hold? I found one on the range and it held 45.5gr, but that seemed like a lot. Only 2% less than 6x47...

That's about right

Should be fine bumping back to 1.354 if that chambers fine.

Why aren’t they fitting your chamber when you bump shoulders back .004?

It’s not ideal, but should fit.

Why aren’t they fitting your chamber when you bump shoulders back .004?

It’s not ideal, but should fit.

I'd shoot for 1.3545, anything that drags on closing set aside and try to find out why. The speed/force and amount of lube used can sometimes influence how much set back you get too...So my fired brass runs 1.356-1.357.

Factory and go gauge are 1.354-1.355.

Am I safe to size back to 1.353? My +0.002" Redding Comp shell holder to run my brass to 1.353-1.354. If I go up to +0.004" I'll get random one or two pieces that won't fit my chamber.

I’ve become a fan of the Wheeler method for setting up sizing dies. If you strictly go by measurements there can be various sources of error. If you go by thousandths until your bolt drops by gravity, you know you’re bumping enough (and not too much).Should be fine bumping back to 1.354 if that chambers fine.

Why aren’t they fitting your chamber when you bump shoulders back .004?

It’s not ideal, but should fit.

I’ve become a fan of the Wheeler method for setting up sizing dies. If you strictly go by measurements there can be various sources of error. If you go by thousandths until your bolt drops by gravity, you know you’re bumping enough (and not too much).

I do the same and compare to what my fired brass measures.

My bolt usually drops free at .002-.003 bump.

Should be fine bumping back to 1.354 if that chambers fine.

Why aren’t they fitting your chamber when you bump shoulders back .004?

It’s not ideal, but should fit.

I'm not getting dragging with a 0.004" bump I'm getting dragging once in awhile if I used the +0.004" shell holder. It only bumps it's back to 1.355" and once in awhile 1.365"

I'm not getting dragging with a 0.004" bump I'm getting dragging once in awhile if I used the +0.004" shell holder. It only bumps it's back to 1.355" and once in awhile 1.365"

Got it now.

I don’t think many people are using the shell holder method. Most are sticky with one and running the die down to the desired bump.

I like this method which was mentioned by @phlegethon

Anyone running Atips at 3k fps?

My calculator shows that as 6.5mil to 1k and a 7mph wind gun.

Pretty impressive numbers.

My calculator shows that as 6.5mil to 1k and a 7mph wind gun.

Pretty impressive numbers.

Anyone running Atips at 3k fps?

My calculator shows that as 6.5mil to 1k and a 7mph wind gun.

Pretty impressive numbers.

I'm going to be doing load development this week with 109s and A-tips

i'm 2990 with A tips and am 6.8mil to 1K at 2000 DAAnyone running Atips at 3k fps?

My calculator shows that as 6.5mil to 1k and a 7mph wind gun.

Pretty impressive numbers.

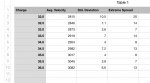

Velocity testing only. Will shoot groups this weekend to go along.

Hornady once fired. Necks were uniformed prior to first firing. 198 rnds on barrel prior to starting.

3 shots each charge over magnetospeed.

109 hybrids jumped .020

Loaded with fx120 v3 auto trickler to within .002 gr

Varget

Starting seeing ejector swipes (see pic) at 36.0.

Temp: 58

Light drizzle rain

Humidity: 82%

Hornady once fired. Necks were uniformed prior to first firing. 198 rnds on barrel prior to starting.

3 shots each charge over magnetospeed.

109 hybrids jumped .020

Loaded with fx120 v3 auto trickler to within .002 gr

Varget

Starting seeing ejector swipes (see pic) at 36.0.

Temp: 58

Light drizzle rain

Humidity: 82%

Attachments

Looks good. I have 109s, varget, hornady brass and dies sitting in my reloading room waiting for my barrel. I was hoping for a comfy 2950 and it seems like it will be possible! What primers?

Looking good. I'm still in the infancy of reloading but snagged 60 rounds worth of pre-rolls from Clay's shop here in OK. Hoping to foul it in and get some magnetospeed numbers while I work out just what kind of reloading set up I want (and where the hell it's all gonna fit in our 1920s craftsman).

Looks good. I have 109s, varget, hornady brass and dies sitting in my reloading room waiting for my barrel. I was hoping for a comfy 2950 and it seems like it will be possible! What primers?

2950 will be on cruise control.

CCI 450’s

Looks good. I have 109s, varget, hornady brass and dies sitting in my reloading room waiting for my barrel. I was hoping for a comfy 2950 and it seems like it will be possible! What primers?

Also just FYI, I shot the first 198 rnds with 34.0 varget. It started out at 2915 or so. I chrono’d it before a match last week at 94rnds.

So, it sped up between 94-198 to 2954. Which is to be expected.

Similar threads

- Replies

- 25

- Views

- 2K

- Replies

- 16

- Views

- 2K

Range Report

6GT Brass Manufacturers and Powder Supply

- Replies

- 36

- Views

- 9K

- Replies

- 20

- Views

- 2K