Anyone know a good smith who can help me chamber a barrel blank to 7.62x54r and rebarrel a mosin nagant rifle? Your suggestions would be greatly appreciated.

Thank you

Gene

Thank you

Gene

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Hello there!Love your rifle!I have a pile of "junk" Mosin Nagant hex actions and have built a few weird rifles with them in the past.I read your build page,very interesting but may I point out a few things?The MN action,particularly the old hex actions like yours,are very strong and rigid.The rear bridge adds little to the action rigidity.These actions are very thick and the left sidewall adds alot of strength to the action.They do have a third lug,the bolt rib that the handle attaches to.I really like your scope mount.I have seen a couple of heavy barrel rifles in 300WM on MN actions and there were no problems.If I can find the parts,I have a replacement bolt head that I made with a standard bolt face,I'll try to post pics.Someone makes an adjustable trigger for them but I can't remember who,Bold,Timney?I wish those stocks were available,they rule.Anyway great job!

Please tell me if you know whether the Finns, or more specifically, the Civil Guard, made any attempts at re-hardening their Mosin receivers. Thanks in advance.Re: Mosin Nagant Build question

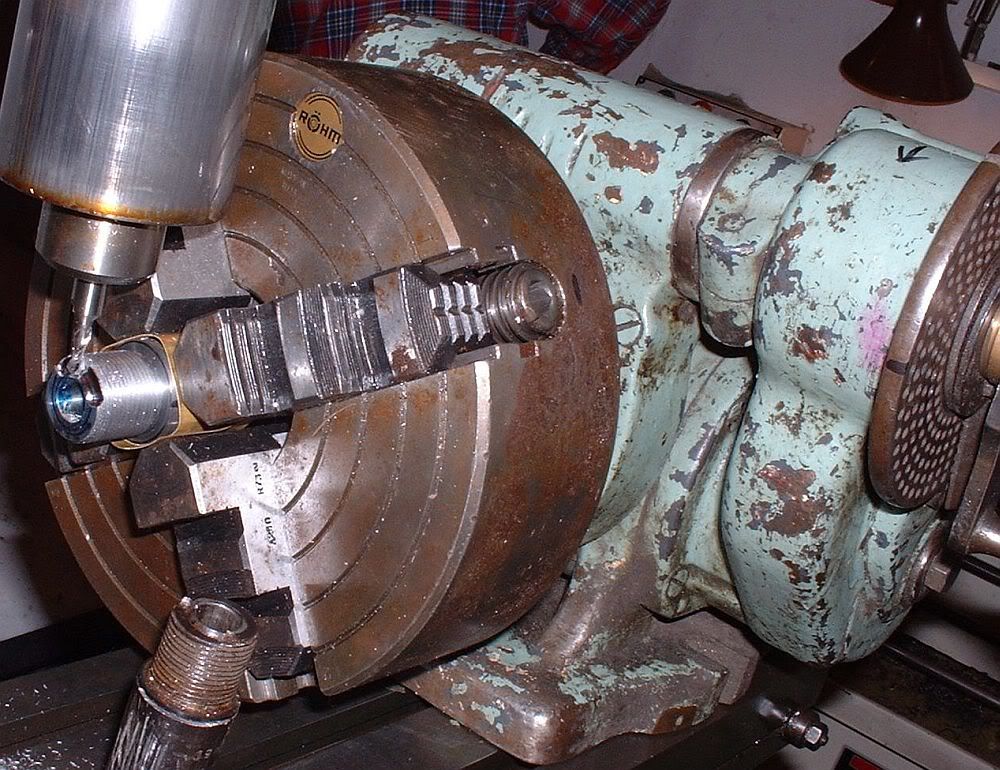

I have rebarreled a number of them, but I am not for hire.

From ~ 1891 to ~1942 they had inner C rings.

From ~1943 to ~ 1958 the did not have inner C rings.

How much would you have to pay for a flat bottomed action with inner C ring manufactured today?

Those are good actions.

I would use the Lapua brass.

I would get the floating pilot reamer.

I would consider the .308" groove barrels, not the .311" groove barrels, for bullet availability.

All rightHonestly, I don't see a reason to do so.

Unlike some other milsurps of questionable alloy/heat treat esp during wartime production MN's did not have this issue. The most prolific rifle ever built to my knowledge with nearly 40 million produced.

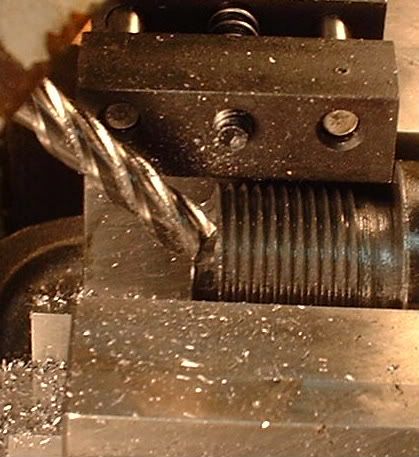

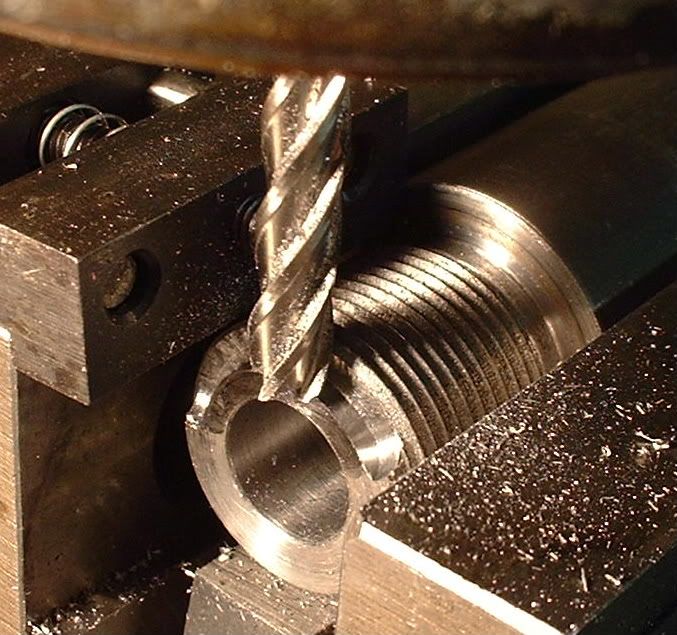

Rebarreling these is mostly straightforward, the extractor cut is a bit of a pain in the ass, and earlier receive rs with the inner C ring may require a relief cut on the breech of the barrel if there's wear to the lug abutments.

All right, Wannashootit, you convinced me.Honestly, I don't see a reason to do so.

Unlike some other milsurps of questionable alloy/heat treat esp during wartime production MN's did not have this issue. The most prolific rifle ever built to my knowledge with nearly 40 million produced.

Rebarreling these is mostly straightforward, the extractor cut is a bit of a pain in the ass, and earlier receive rs with the inner C ring may require a relief cut on the breech of the barrel if there's wear to the lug abutments.

Re: Mosin Nagant Build question

I've done it, and I didn't limit the caliber to 54R, at one point I had one in 30-30 and 22-250. I was learning how to work on things and it was a cheap action to learn on if I screwed it up.

Currently I'm thinking about making one into a 45-70.

I agree with Clark, I would use a 308 barrel blank, the floating pilot reamer is generally better IMO, but it depends on exactly what you want to do with this. I turned a reamer from a piece of A2, and used it to cut several chambers, the all shoot just dandy.

If you want a sub MOA hammer you can get that by making your own reamer, if you want a 1/4 MOA stick go buy a reamer from Mr. Kiff or someone who makes them for a living.

As much as people like to knock the CR rifles, remember that 70 years ago people used them successfully to kill enemy soldiers at the ranges we all shoot matches with. I have a k31 that will first round hit a 8" square plate any day of the year at 400y. Open sights and surplus ammo. Just like the 9mm vs. 45 debate; whomever thinks that they're absolute junk go stand at 600y and let me take 5 shots at them.

I got some drill rod and heated it up til cherry red, then dropped it in a can of motor oil.If you don't mind me asking a question what did you do to harden your reamer? I tried to do this once for a home brew9mm reamer and it didn't seem to harden correctly.

I entered here with the question of whether I should do anything about the level of hardness of my hexagonal Mosin receiver before building it into a modified Finnish M28/30. My question concerning hardness has been answered.

I did the re-design of the project, but I’m farming the work out to a gunsmith and a woodworker. Is anyone here still interested in what I’m doing, or is this forum purely for the hands-on type?

I got some drill rod and heated it up til cherry red, then dropped it in a can of motor oil.

Normalized it by sticking it in a toaster oven on "toast" for about 30 mins

It worked OK. I wouldn't do it that way these days. That was back when I had a lot more time than disposable income.