Factory ammo that I measured was 1.1825 measured at the datum line, that was an example of 10 cases that I measured... unfired.

Ammo fired from my bolt gun measured 1.186... ammo fired from one of my DI guns measured 1.190.

SAAMI spec to the datum line is 1.190 -.007... so 1.183 to 1.190 is spec for this cartridge.

The Hornady rounds were just under minimum spec by .0005, but that is splitting hairs on the measuring. I was actually surprised at the consistency of the factory rounds.

I think what you are seeing is normal case expansion of the case above the web, I to see this on my cases and that is out of four different rifles. It almost disappears after full length resizing. And some of my cases have been loaded 8 or 9 times, I have not yet lost a case to it having loose primer pocket or any signs of weakening from firing. I think it is just a characteristic of this round along with light ejector swipes on the DI guns.

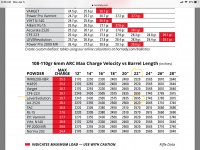

I have shot and reloaded a lot of 6mm ARC, and always have loaded under max load per Hornady and Hodgen spec.

Ammo fired from my bolt gun measured 1.186... ammo fired from one of my DI guns measured 1.190.

SAAMI spec to the datum line is 1.190 -.007... so 1.183 to 1.190 is spec for this cartridge.

The Hornady rounds were just under minimum spec by .0005, but that is splitting hairs on the measuring. I was actually surprised at the consistency of the factory rounds.

I think what you are seeing is normal case expansion of the case above the web, I to see this on my cases and that is out of four different rifles. It almost disappears after full length resizing. And some of my cases have been loaded 8 or 9 times, I have not yet lost a case to it having loose primer pocket or any signs of weakening from firing. I think it is just a characteristic of this round along with light ejector swipes on the DI guns.

I have shot and reloaded a lot of 6mm ARC, and always have loaded under max load per Hornady and Hodgen spec.