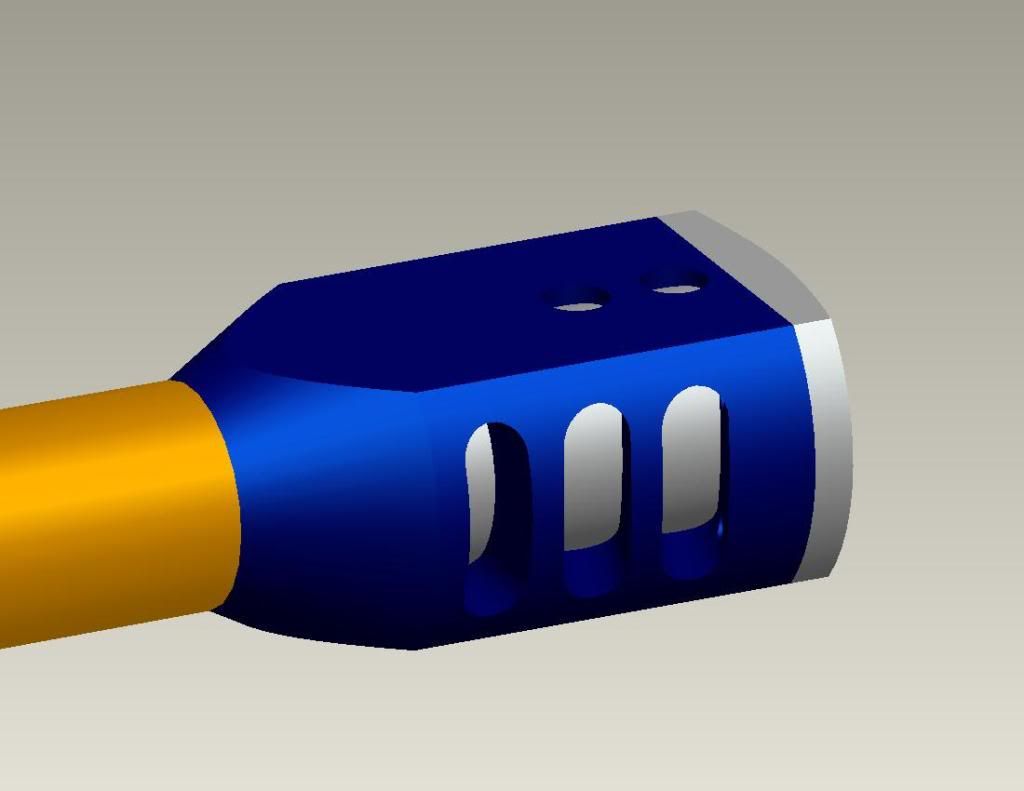

I hope I have come up with something that may be a viable solution to a common issue with muzzle brakes, shooting with other people around. It may not be an issue to you, but I'm sure you've had more than one dirty look. I have heard of some people designing a cover for the outside or having the brake clamp on the threads. Both of these solutions work to some extent but have their drawbacks.

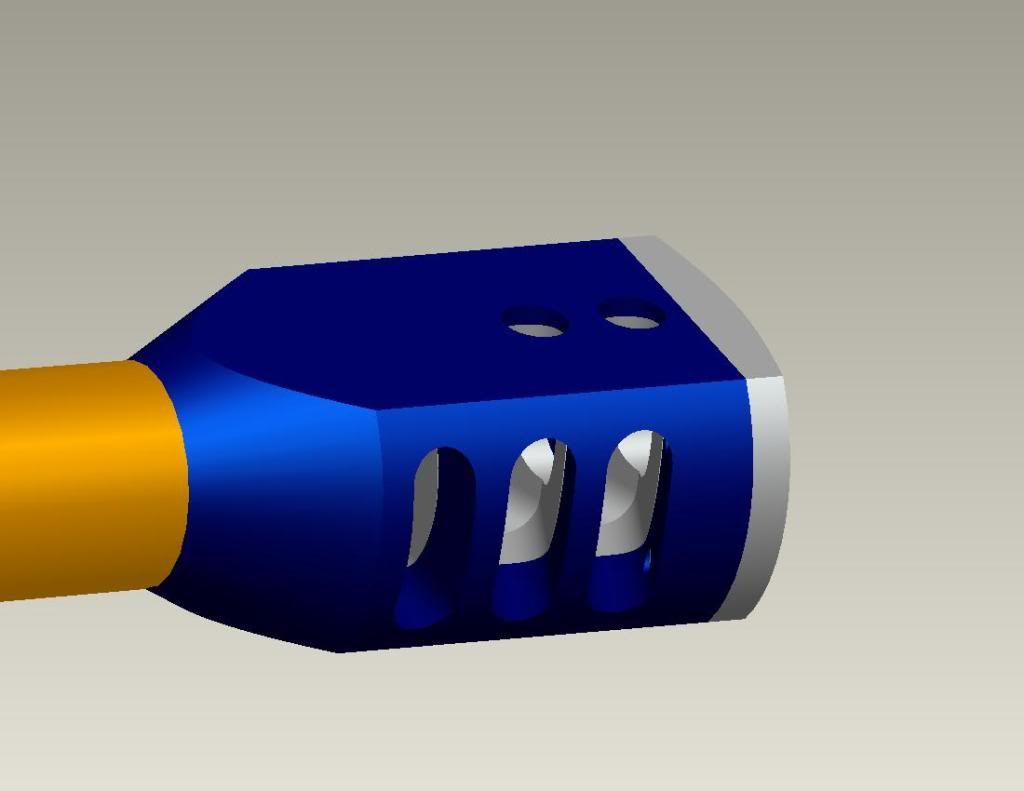

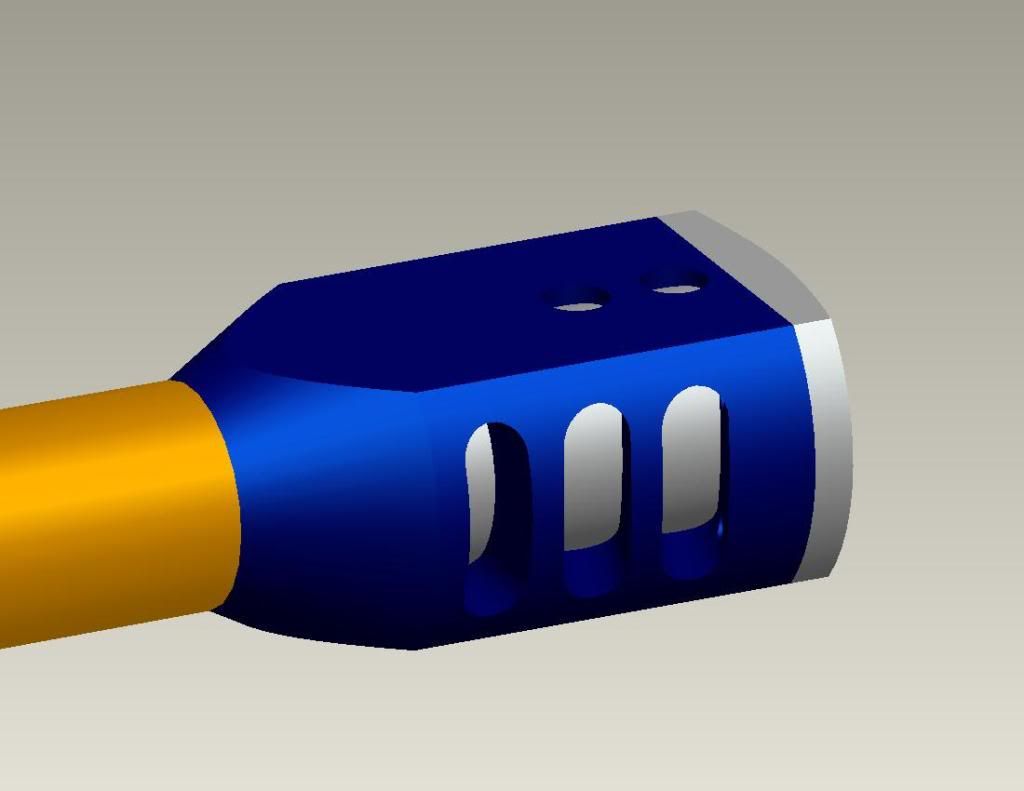

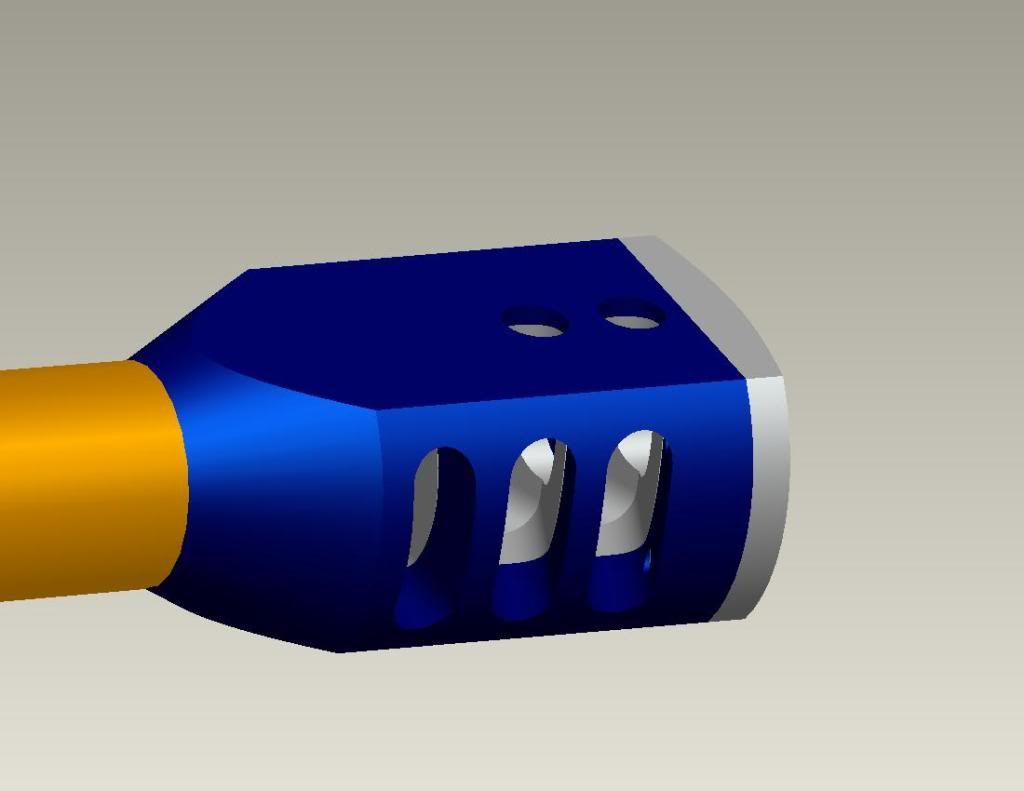

I got to thinking a drawing and came up with this. Let me know what you think.

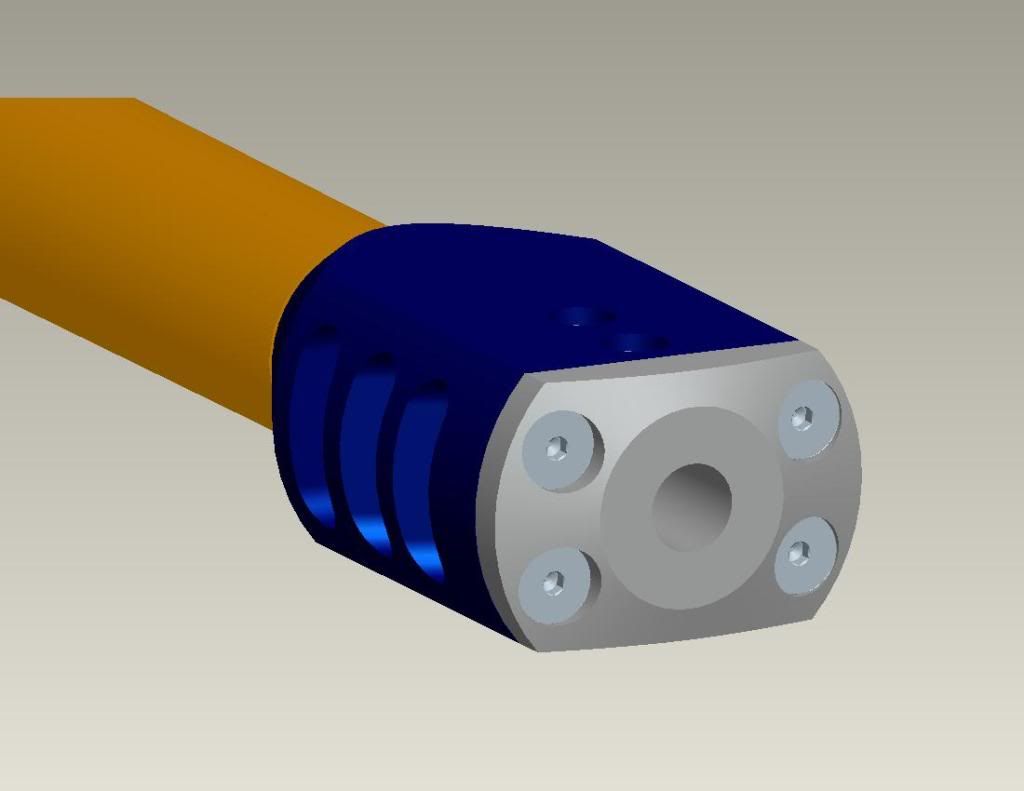

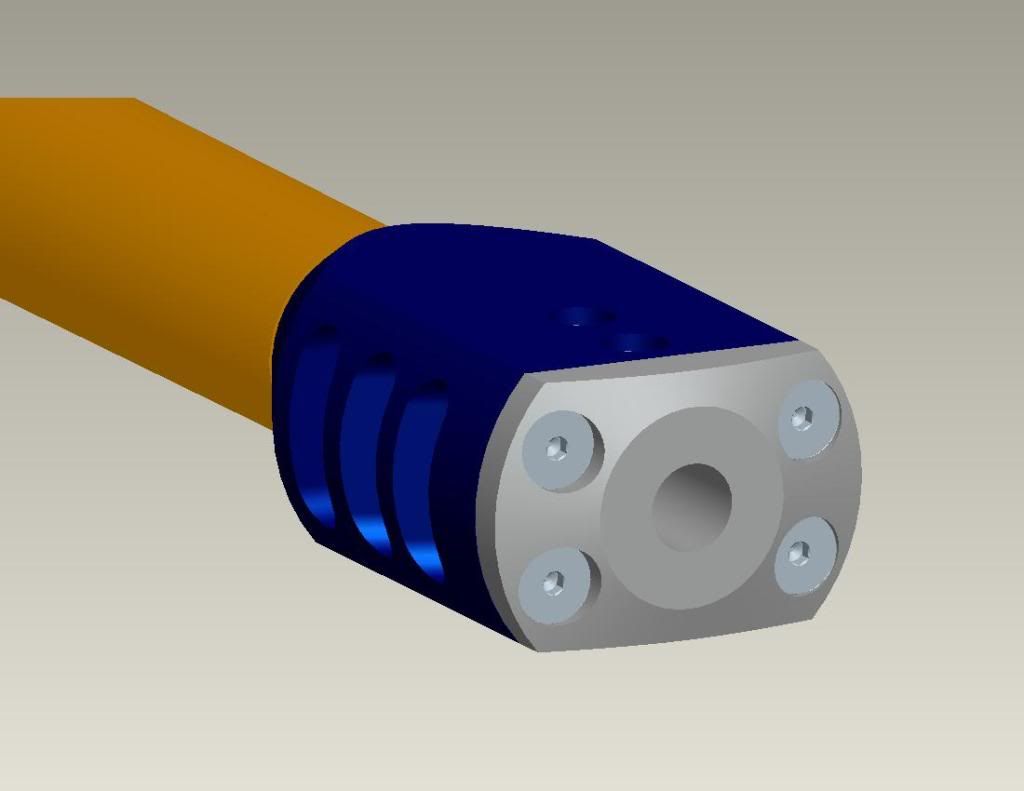

It has two inserts. One with the slots and one solid.

My only concern is of the screws not holding. Hopefully with all of your backgrounds, someone can give me some insight.

Thanks,

Matt

I got to thinking a drawing and came up with this. Let me know what you think.

It has two inserts. One with the slots and one solid.

My only concern is of the screws not holding. Hopefully with all of your backgrounds, someone can give me some insight.

Thanks,

Matt