I will start by saying that I am not a "real" machinist by trade.

My full time job is a product manager in a software company, but I've always enjoyed making physical stuff when I'm done creating digital things at work. Got a Tormach CNC mill a few years back, made things like Picatinny rail for LMSS scope, Ckye bipod adapter, and such some here may have bought. Early this year upgraded to a proper industry-grade VMC and have been looking at other things to do to pay for my ammo.

One service I am looking at providing is slide milling for red dot, and just surprised at what some places are doing. Won't name names but just want to share what I found.

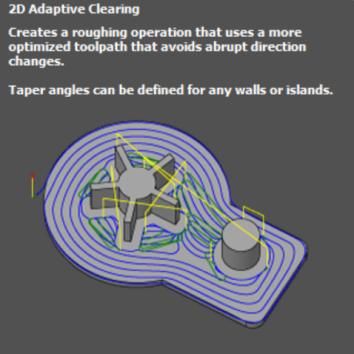

Exhibit A - notice the "wavey" pattern? It is the result of "adaptive" tool path generated from CAM software, which is designed for roughing (bulk material removal) and not finishing. Because it is not designed for finishing the floor of a flat surface, and that end mills are not perfectly flat at the bottom, when used with a large step overs (distance between the waves) it leaves marks high enough that won't even go away after sand blasting, as seen from the photo after Cerakote.

2D adaptive clearing toolpath from Fusion 360 - "Creates a roughing operation...".

My full time job is a product manager in a software company, but I've always enjoyed making physical stuff when I'm done creating digital things at work. Got a Tormach CNC mill a few years back, made things like Picatinny rail for LMSS scope, Ckye bipod adapter, and such some here may have bought. Early this year upgraded to a proper industry-grade VMC and have been looking at other things to do to pay for my ammo.

One service I am looking at providing is slide milling for red dot, and just surprised at what some places are doing. Won't name names but just want to share what I found.

Exhibit A - notice the "wavey" pattern? It is the result of "adaptive" tool path generated from CAM software, which is designed for roughing (bulk material removal) and not finishing. Because it is not designed for finishing the floor of a flat surface, and that end mills are not perfectly flat at the bottom, when used with a large step overs (distance between the waves) it leaves marks high enough that won't even go away after sand blasting, as seen from the photo after Cerakote.

2D adaptive clearing toolpath from Fusion 360 - "Creates a roughing operation...".

Last edited: