Loaded 50 rds of 9mm using Xtreme CPRN 115gr. Used 4.3gr Bullseye…range results were excellent with Colt Commander, SW M&P. Accuracy was excellent…...however got several stovepipes with Sig P320 (M18). Considering moving to 4.6gr Bullseye to ensure cycling with Sig.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

Cool quick change plate on the bench.

How you liking the Zero press?I’ve started my reloading process. All I got done yesterday is;

• measured 12 of the cases neck widths and got the mean & medium (0.0136 / 0.013621)View attachment 7689939

• annealed 100 of the virgin Lapua brass LRP (AMP Mark II)

• expanded using .265 mandrel to obtain uniform neck openings View attachment 7689940

• got the SAC sizing die setup with .289 bushing & .2625 mandrel installed

• tested sizing die using 3 Hornady cases that I also put through the same processes

• confirmed setup on the Henderson Precision trimmer to 1.910”, trimming the Hornady cases

Tonight the goal is to size and trim all 100 of this 1st batch and anneal the next set of 100.

Rainy day here (much needed). Primed, powdered, and seated some 260 Rem.

Technically yesterday. Cast .357 and .355 bullets for a good part of the afternoon. Late in the evening, sized and lubed .312 bullets. Today, going (hopefully) to be reloading a bunch of handgun rounds. Also have 250 rounds of brass cleaned and ready to load for the RPR and maybe 50 for the MPA.

Went to the range to find what it takes to hit 2700 FPS in a BR with 112 MatchBurners... Only to have my 9 volt die in my MagnetoSpeed after 3 shots. Luckily my starting charge was maybe .1 - .2 under where I need to be.

Pulled all my unshot ammo apart and built up a seating depth test with my guessing charge to see if I can improve upon the group size.

Pulled all my unshot ammo apart and built up a seating depth test with my guessing charge to see if I can improve upon the group size.

Brass that has been fired through my new barrel once.

Annealed, cleaned, FL bump sized, trimmed, chamfured, deburred, primed, trickled and used a magnifying glass on the 505 to get powder perfect and seated bullets. These seated the easiest and smoothest Ive ever done. Hope to tighten my group at 1,000 yards. If I can shoot a 5 shot group under 8 inches at 1,000 I will be done experimenting and this will be THE load.

Annealed, cleaned, FL bump sized, trimmed, chamfured, deburred, primed, trickled and used a magnifying glass on the 505 to get powder perfect and seated bullets. These seated the easiest and smoothest Ive ever done. Hope to tighten my group at 1,000 yards. If I can shoot a 5 shot group under 8 inches at 1,000 I will be done experimenting and this will be THE load.

Loaded some 6.8 spc with 100 gr gmx. Hoping to get ladder test done by the end of the week. If anyone has any info on these rounds. Would appreciate it.

Annealed 200 pieces of 25 creed and 100 pieces of 6 creed. FL sized, bumped, trimmed, chamfered and deburred them. Pulled primers and started cleaning my 223 brass from my pressure test yesterday and started loading up where it seemed a node may be for testing. 70gr rdf at 3100-3160fps!! Screaming quick, no pressure signs, I’m okay with that!! Looking forward to seeing how this pans out.

What powder? I'm using 33.7 gr. of H4350 behind them and getting around 2850 in a 6mm Dasher. That load is more than 2 gr. under max. I'm thinking if you looked at H4350 or possibly RE-17 you could get it. Fiddle with seating. I've been on and off the lands and they are holding around 2/3's MOA @ 300 and 400. Which is alright for F-Class. Not so much straight bench.Went to the range to find what it takes to hit 2700 FPS in a BR with 112 MatchBurners... Only to have my 9 volt die in my MagnetoSpeed after 3 shots. Luckily my starting charge was maybe .1 - .2 under where I need to be.

Pulled all my unshot ammo apart and built up a seating depth test with my guessing charge to see if I can improve upon the group size.

@sandwarrior

26” Barrel

Peterson Brass/CCI BR

SW Precision

112 MatchBurner

29.9 - 2686 with good ES/SD

30.0 - 2693 with good ES/SD

I’ve got them at 0.035” off the lands and they are staying in the .2 - .4 MOA range for me.

My only gripe is that, as long as they are it’s difficulty to get them to seat straight for me for some reason. My run-out is above where I’m use to with Berger 105’s but the gun doesn’t seem to give a shit.

26” Barrel

Peterson Brass/CCI BR

SW Precision

112 MatchBurner

29.9 - 2686 with good ES/SD

30.0 - 2693 with good ES/SD

I’ve got them at 0.035” off the lands and they are staying in the .2 - .4 MOA range for me.

My only gripe is that, as long as they are it’s difficulty to get them to seat straight for me for some reason. My run-out is above where I’m use to with Berger 105’s but the gun doesn’t seem to give a shit.

Something I have not had a big problem with yet but?

Would a short stroke to start it then lift before completing the stroke do any good for you?

I do this on my 300 blk with the long 220gr fbrn. Seems to let case "scooch" around slightly and realign.

No actual measurements taken just checking on a granit block for wobble.

Use what I have. Lol

Would a short stroke to start it then lift before completing the stroke do any good for you?

I do this on my 300 blk with the long 220gr fbrn. Seems to let case "scooch" around slightly and realign.

No actual measurements taken just checking on a granit block for wobble.

Use what I have. Lol

Continuing my rampage against the scraps from other projects I added some shelves to my second bench for brass storage.

Limited space on one side of the garage. Next step will be improving under-bench storage with shelves to get the last things out of the blue tubs.

My reloading area is kind of like the Atlanta VA hospital - added onto as time and money permits heheh.

Limited space on one side of the garage. Next step will be improving under-bench storage with shelves to get the last things out of the blue tubs.

My reloading area is kind of like the Atlanta VA hospital - added onto as time and money permits heheh.

Today I primed 102 Remington cases. Tomorrow I will load powder and bullets. Thursday I am headed to the range.

Knocked the dust off of my K&M expander mandrel for setting neck tension, only to be reminded of why it was collecting dust.

Trying to troubleshoot where/why this mandrel wants to introduce a lot of added run-out into my case necks just makes me see more dollar signs.

Trying to troubleshoot where/why this mandrel wants to introduce a lot of added run-out into my case necks just makes me see more dollar signs.

If you stop measuring runout, you won’t have that problem. Most would say neck tension is far more important.Knocked the dust off of my K&M expander mandrel for setting neck tension, only to be reminded of why it was collecting dust.

Trying to troubleshoot where/why this mandrel wants to introduce a lot of added run-out into my case necks just makes me see more dollar signs.

never have i measure run out , and never will .If you stop measuring runout, you won’t have that problem. Most would say neck tension is far more important.

finished resizing 6 boxes of brass roughly 3k pieces including using mandrels on all of them now I got to trim and clean them all Yea really going to have to count all my brass someday just not today , preparing to unload 100 ish rounds and try to recapture the powder and primers to reuse later this week . Also finished cleaning out that barrel as it will be hitting 6900 rounds this weekend I hope .

If you stop measuring runout, you won’t have that problem. Most would say neck tension is far more important.

I'd agree with you on that, and it shoots well as it is currently. Part of me is trying to asses my methods of using a mandrel and validate a proper method of employing it, as it isn't regularly used in my brass prep process and I'd like to incorporate it... as correctly as I can.

I have been running the mandrell after trim and champher.

I dip the neck in grafite then run mandrell leaving the remaining grafite in the neck for seating.

Not sure if this is best practice. Loads definitely improved with mandrell use.

I dip the neck in grafite then run mandrell leaving the remaining grafite in the neck for seating.

Not sure if this is best practice. Loads definitely improved with mandrell use.

Again......nothing in the reloading room. But, have spent 2 days working on something shooting related!

Working on our range here at our home! The black object in the left side of the photo is my 300 yard target frame!

We’ve had a 300 yard range with a backstop at our home for about 20 years. But, it was impractical for semi-auto handgun work, as the brass was near unrecoverable......so, we did very little practice with our defense handguns.

We cleaned an area of about 60 feet wide and 40 feet in front of the berm. Then we put about 36 yards of road-base (sand/rock/clay mix) on the cleaned area. Also added about 12 yards of sand to the front of the dirt berm! This will allow us to be able to move about in a more tactical manner while engaging our targets and recover most of our brass.

Working on our range here at our home! The black object in the left side of the photo is my 300 yard target frame!

We’ve had a 300 yard range with a backstop at our home for about 20 years. But, it was impractical for semi-auto handgun work, as the brass was near unrecoverable......so, we did very little practice with our defense handguns.

We cleaned an area of about 60 feet wide and 40 feet in front of the berm. Then we put about 36 yards of road-base (sand/rock/clay mix) on the cleaned area. Also added about 12 yards of sand to the front of the dirt berm! This will allow us to be able to move about in a more tactical manner while engaging our targets and recover most of our brass.

Last edited:

That's an awesome set upAgain......nothing in the reloading room. But, have spent 2 days working on something shooting related!

Working on our range here at our home! The black object in the left side of the photo is my 300 yard target frame!

We’ve had a 300 yard range with a backstop at our home for about 20 years. But, it was impractical for semi-auto handgun work, as the brass was near unrecoverable......so, we did very little practice with our defense handguns.

We cleaned an area of about 60 feet wide and 40 feet in front of the berm. Then we put about 36 yards of road-base (sand/rock/clay mix) on the cleaned area. Also added about 12 yards of sand to the front of the dirt berm! This will allow us to be able to move about in a more tactical manner while engaging our targets and recover most of our brass.

Reworked my process and the brass above and got my run out as consistently low as it’s ever been with an expander mandrel.

That's an awesome set up

Thanks! Been wanting to do this for a long time......money and many “have to’s” interfered with the “want to’s”!

Could you list your process? Thinking about getting a mandrel, but don't know if its worth the gains.Reworked my process and the brass above and got my run out as consistently low as it’s ever been with an expander mandrel.

Does your low runout ammo shoot tighter groups?

Preface: I use a RCBS Reloader Special made in 1980 that has more wiggle room than a WW2 1911, so your mileage may vary...Could you list your process? Thinking about getting a mandrel, but don't know if its worth the gains.

Does your low runout ammo shoot tighter groups?

To keep run-out down while using the mandrel (yes, I isolated the run out to being caused by the mandrel), I had to remove the spring clip on my shell holder, clean the face of my tan and my shell holder, and be VERY meticulous abound how the case mouth approaches the mandrel (spin the case under the weight of the handle, and give the shell holder a spin).

Ive only had a chance to shoot the reloads that used a mandrel with runout I’m happy with to 600, and no, groups were not substantially better. My ES/SD was down about 20% though.

Instructions on the mandrell say to let it float so the other things would not make a difference.

Too many top shelf shooters using mandrells to count.

There has to be something else causing problems as in a worn out press? Possibly you could shim some of the play out.

The mandrell pins will center themselves inside the case.

Too many top shelf shooters using mandrells to count.

There has to be something else causing problems as in a worn out press? Possibly you could shim some of the play out.

The mandrell pins will center themselves inside the case.

set up another 200 pieces of brass primed waiting for powder to be chosen for Sundays shooting  also my air mattress pump arrived lol and it moves a lot more air than my chamber chiller and is 1/2 the price , noisy little bugger but I don't care about noise need to try it with the hose and make sure it fits in the chamber . sort of neat little toy for cooling the chamber while at the range it's powdered by its own rechargeable battery .

also my air mattress pump arrived lol and it moves a lot more air than my chamber chiller and is 1/2 the price , noisy little bugger but I don't care about noise need to try it with the hose and make sure it fits in the chamber . sort of neat little toy for cooling the chamber while at the range it's powdered by its own rechargeable battery .

Last edited:

Loaded a 7SAW seating depth test, headed to the range and shot it. Chrono numbers look decent, but I’m not real happy with the accuracy results so I’m gonna try again with a lower charge weight. I’m near top end of pressure, so I’m hoping dropping velocity a little will settle down the accuracy.

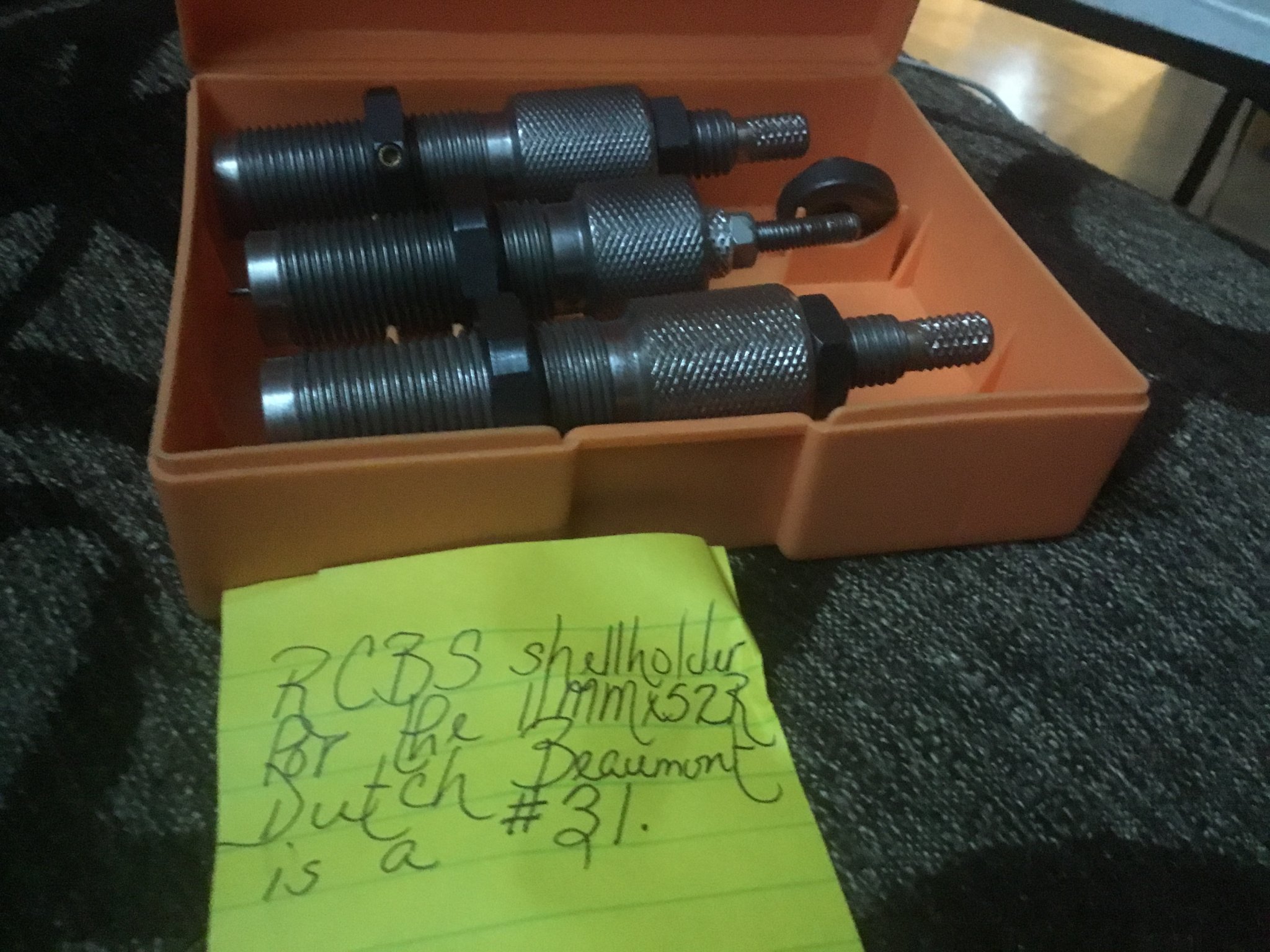

Marveled at my 11x52R die set and wondering if I should ever attempt to find some brass, cast bullets (or cast bullet mold) and accompanying black powder to shoot the Beaumont Vittali that my mother gifted to me for Christmas in 1969

. (pictured below the mounts)

. (pictured below the mounts)

The mandrel holder is 1/4 turn past co tact with an o-ring under the lock nut. The mandrel is tight in the body.Are you letting the mandrel float or did you add a lock ring?

Im fairly certain it is my old as dirt press giving me problems. RCBS is sending me a free set of new pins for it, but floating the shell holder and rotating stuff seemed to help.

I shot another 10 FL sized and 10 FL then mandrel this evening with the kids, round robin style. ES/SD decently lower with the mandrel. Accuracy was at about the same for both groups of 10.

The mandrell should move freely in the die body. Free float to find center. But not slide or rattle around.

The mandrel holder is 1/4 turn past co tact with an o-ring under the lock nut. The mandrel is tight in the body.

Im fairly certain it is my old as dirt press giving me problems. RCBS is sending me a free set of new pins for it, but floating the shell holder and rotating stuff seemed to help.

I shot another 10 FL sized and 10 FL then mandrel this evening with the kids, round robin style. ES/SD decently lower with the mandrel. Accuracy was at about the same for both groups of 10.

My K&M mandrel did not come with any type of lock ring. It's designed to self center

Mine definitely did, though I bought the kit probably 12 years ago for neck turning.My K&M mandrel did not come with any type of lock ring. It's designed to self center

I'm loading up another 40 this morning to do a final check on SD/ES, re-zero and double check suppressor shift, then I'm done fucking with it and will just incorporate it into my brass prep.

I like the easy button. I'm so over tinkering with stuff that doesn't really pay off for casual steel shooting.

BTW, I have you beat. My K&M was bought in 2001 for the same reason.

BTW, I have you beat. My K&M was bought in 2001 for the same reason.

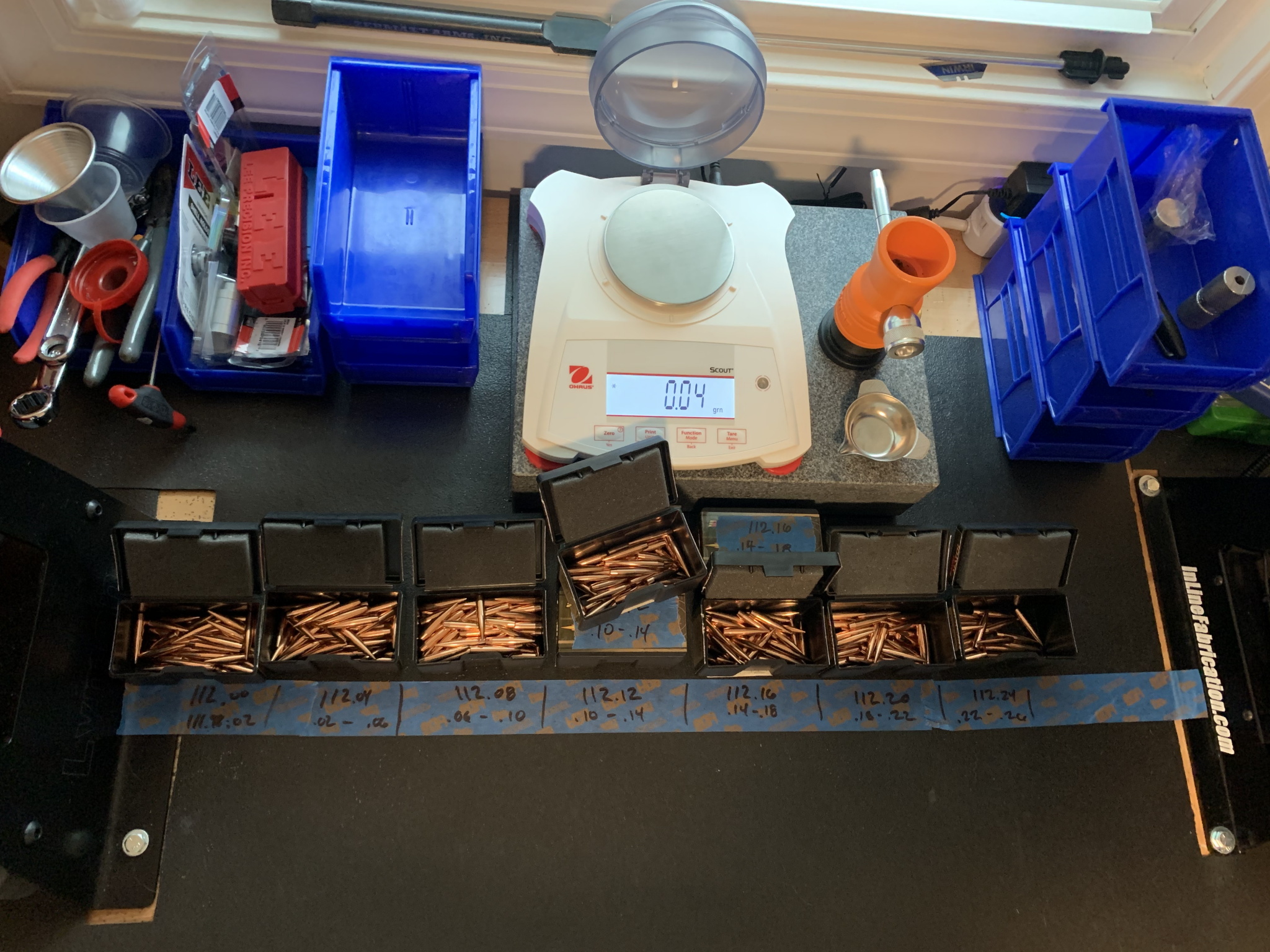

First time sorting bullets for me... just wanted to see if I'll actually notice any improvement downrange. .243/6mm 112gr Barnes Match Burners

... not sure if what I'm seeing is good or bad because I've never really weighed bullets before, but so far I've opened a lot of boxes and I still don't have 300 of the exact same weight and I'm pretty burnt out on doing it already.

I almost hope that I don't see any obvious improvement on-target, because I'd rather never do this again. This sucks.

(I know the scale isn't showing zero, I had just turned on the ceiling fan.)

... not sure if what I'm seeing is good or bad because I've never really weighed bullets before, but so far I've opened a lot of boxes and I still don't have 300 of the exact same weight and I'm pretty burnt out on doing it already.

I almost hope that I don't see any obvious improvement on-target, because I'd rather never do this again. This sucks.

(I know the scale isn't showing zero, I had just turned on the ceiling fan.)

Co-ax went to a happy, new owner. So, I mounted up the new shiny early this morning.

Mike, I 100% agree. Everyone on YouTube has a this matters/this doesn’t list. I’m just at the point where I’m trying everything obscure for myself, eliminating variables and seeing what works and is worth the ass pain.I like the easy button. I'm so over tinkering with stuff that doesn't really pay off for casual steel shooting.

BTW, I have you beat. My K&M was bought in 2001 for the same reason.

Im to the point though where I’d rather be shooting than loading.

Contrary to everything I just said, I just upgraded the indicators on this guy...

Last edited:

Stop measuring run out. Run a mandrel and load the bullet. I do probably far less than most hand loaders on this site and shoot tiny groups like the rest of them, and I ain't that good of a group shooter. Hell, let me give u the story on this particular batch of ammo. Last year, the week before a match, I was doing my thing as per usual; loading at the last minute. I lobbed my brass with hornady one shot and threw them into the tumbler. The tumbled for a few minutes and I went over to the tumbler for some unknown reason and felt the tumbler. The motor felt pretty damn hot. This was a harbor freight tumbler that I had just bought because I accidently broke the lid of my 21st century tumbler so I was in a pinch. The heat from the motor worried me so I turned it off and looked at the brass. It looked pretty clean so my lazy ass said "eh, good enough." I took the brass out and loaded 200 pieces. Next day (couple days before an out of town match), I wanted to check my zero. Ill be damned if my 1/4 MOA load wont shooting 1.5 MOA at 100 yards. I, for the life of me, couldn't figure it out. Ended up screwing on the 6.5cm barrel on the AI and shot factory ammo for the match. Talked to some buddies of mine at the match whom are Fclass shooters and they said it was probably lube left in the necks. Once I got home, I pulled 5 bullets, one by one, dumbed the powder into a cup, brushed the ID of the necks, poured powder back in, seated bullets and went to shoot. 1 hole group. Never touched the outsides of the necks before seating bullets, nothing. Fast forward a year to last week. Ive got a match coming up. I pulled ALL the bullets 1 by 1, poured powder brushed necks, blah blah blah, went outside when I was done to shoot some of them. I haven't shot that rifle or ANY rifle at 100 since April and this was the 1st three rounds down the tube of this year old Frankenstein ammo.

Point being this:

All of the minutiae doesn't matter. Worry about the core principles of loading good ammo, and don't sweat the rest. Powder charge and seating depth are way more critical.

Point being this:

All of the minutiae doesn't matter. Worry about the core principles of loading good ammo, and don't sweat the rest. Powder charge and seating depth are way more critical.

farted around with my annealeez and start pulling about 150 rounds I need to take apart to reclaim the powder and primers and bullets . Sadly I only got to 6 of them where are the keebler elves when you need them . but on a good note I was able to run power in the shed so I got some lights till I can get a power service run and mosquitos by the millions just have to save up to get plumbing .