A good friend ordered a Makerbot Replicator 2 a few weeks ago. This model prints in PLA with a maximum resolution of 100 microns within a print volume of 11.2 in x 6 in x 6.1 in. It finally arrived yesterday, so we spent a couple hours last night setting it up and printing a couple samples. Set up was super easy, the calibration process is well documented and really only consists of adjusting the print surface to match the horizontal movement of the extruder head. More info: https://store.makerbot.com/replicator2.html

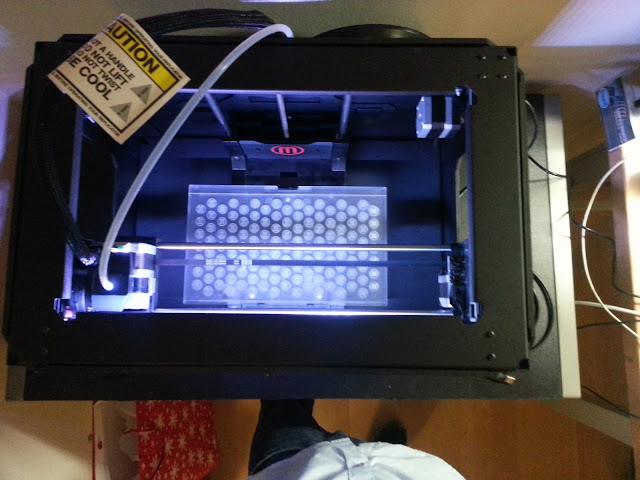

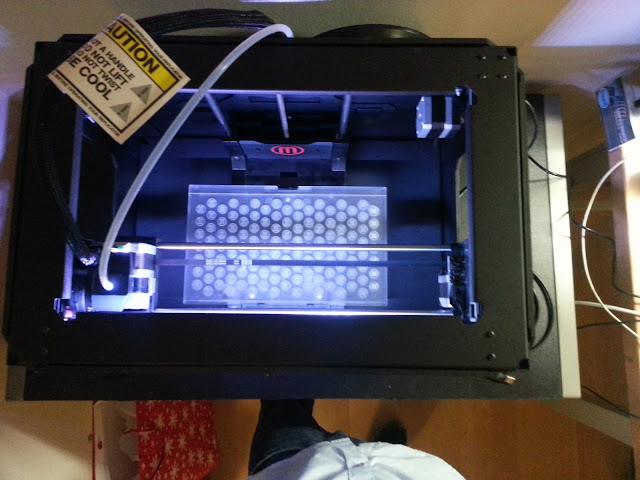

In its new home and plugged in:

Top view of the print surface:

The interface is very user friendly. The setup steps detailed in the manual are also displayed on the lcd display.

Video of first print:

https://picasaweb.google.com/lh/photo/OrLaQXvoSeN2TfKqVWHEENMTjNZETYmyPJy0liipFm0?feat=directlink

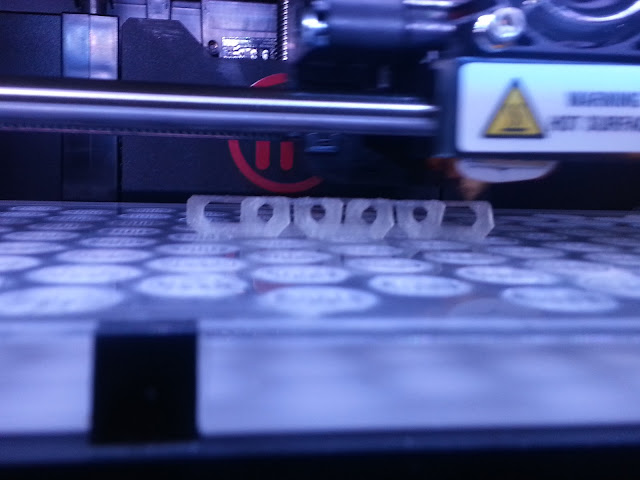

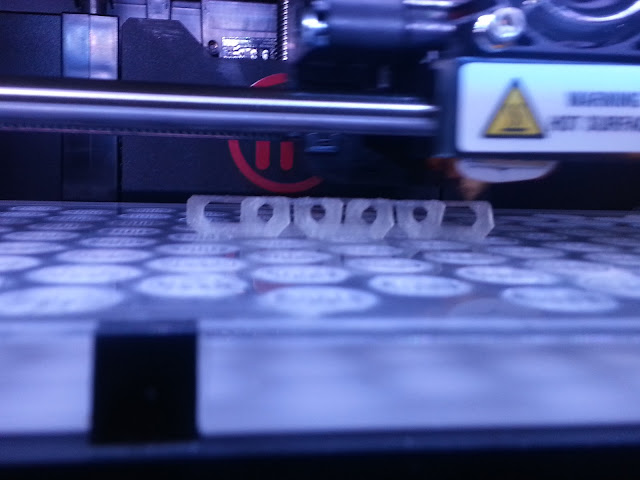

The first item we printed was a chain with 5 links. Here are a few pictures of it's progression, taken after the previous video.

Finished!

The estimated production time for this piece was listed as 15 minutes, but it was finished in 11. The next item, a paired nut and bolt was listed as 55 minutes, iirc, and was completed in 22. Well ahead of schedule, I'm not sure why this is. We noticed that that makerbot logo engraved on the print surface was also visible on the links of the chain. For this reason, we inverted the print surface for the nut and bolt. It's surface isn't as smooth, so the finished parts stuck a bit more, but the logos didn't influence the surface finish.

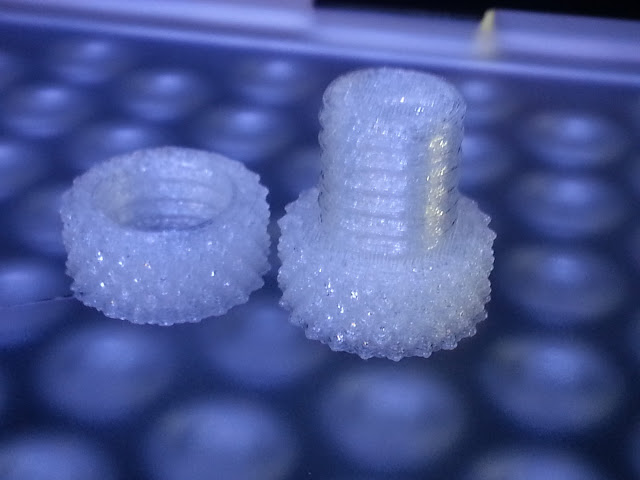

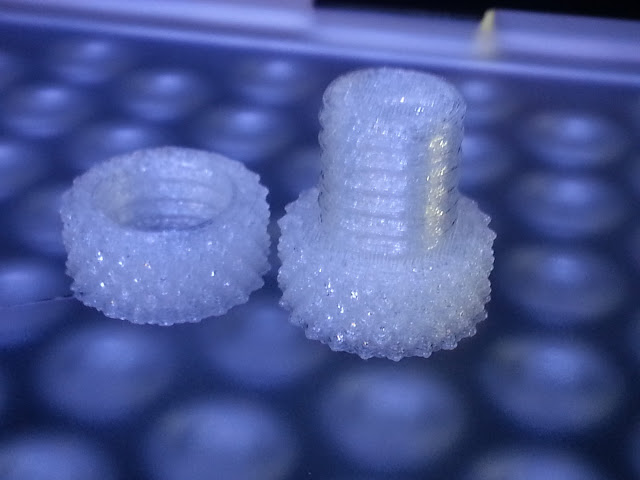

Finished nut and bolt:

In its new home and plugged in:

Top view of the print surface:

The interface is very user friendly. The setup steps detailed in the manual are also displayed on the lcd display.

Video of first print:

https://picasaweb.google.com/lh/photo/OrLaQXvoSeN2TfKqVWHEENMTjNZETYmyPJy0liipFm0?feat=directlink

The first item we printed was a chain with 5 links. Here are a few pictures of it's progression, taken after the previous video.

Finished!

The estimated production time for this piece was listed as 15 minutes, but it was finished in 11. The next item, a paired nut and bolt was listed as 55 minutes, iirc, and was completed in 22. Well ahead of schedule, I'm not sure why this is. We noticed that that makerbot logo engraved on the print surface was also visible on the links of the chain. For this reason, we inverted the print surface for the nut and bolt. It's surface isn't as smooth, so the finished parts stuck a bit more, but the logos didn't influence the surface finish.

Finished nut and bolt: