If I was a custom barrel maker with an urge to be original I would make some .277 caliber nickel alloy steel barrels in 1:8 twist, and chamber them in the 277/308 Win using either necked up .260 Peterson SRP or necked up 308Win SRP brass. Set up the barrel for a piezoelectric pressure machine and develop some loads at a 70,000PSI peak pressure using high BC copper bullets in a strong bolt action. Scope the gun every 100 shots to detect progression of any fire cracking and see when throat erosion occurs. If barrel life was clearly extended abd bullet speeds were significantly above 270 Win or 270 WSM published speeds, I would appeal to guys who do a lot of wildcatting first. There is some lisbility to doing this, but at least using 308Win parent cases expense would be minimized. As long as loads were carefully pressure tested and an appropriate disclaimer issued, I think the legal risk would be limited. The primer is potentially the weak spot, and that is why SRP mag primers would be used.In my opinion this is just part 2 of Stoner's legacy coming to fruition, with companies finally being forced to explore materials that are standard use in other industries but haven't been used in firearms until now (due to cost) to remain competitive. Consumer demand for innovation is there, and so far both the Spear and SFAR are proving there is a market for items carrying a slightly higher pricetag if the extra performance is there.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

80,000 PSI capable actions for Sig Fury

- Thread starter Noobilicious

- Start date

Why not just make that barrel and use hybrid 277 fury cases?If I was a custom barrel maker with an urge to be original I would make some .277 caliber nickel alloy steel barrels in 1:8 twist, and chamber them in the 277/308 Win using either necked up .260 Peterson SRP or necked up 308Win SRP brass. Set up the barrel for a piezoelectric pressure machine and develop some loads at a 70,000PSI peak pressure using high BC copper bullets in a strong bolt action. Scope the gun every 100 shots to detect progression of any fire cracking and see when throat erosion occurs. If barrel life was clearly extended abd bullet speeds were significantly above 270 Win or 270 WSM published speeds, I would appeal to guys who do a lot of wildcatting first. There is some lisbility to doing this, but at least using 308Win parent cases expense would be minimized. As long as loads were carefully pressure tested and an appropriate disclaimer issued, I think the legal risk would be limited. The primer is potentially the weak spot, and that is why SRP mag primers would be used.

Excellent question. My thinking was use available brass that will withstand higher than SAAMI pressure. Also I don’t know that available bolt actions would handle 80000PSI. I have been testing 150 gr solids from my 308 Win and LVR powder from a 26” Savage barrel and getting 3150 fps safely with Lapua SRP brass. Without pressure equipment hard to tell where the peak pressure is, though. The nickel steel barrel in overbore cartridges should have greater throat life. The 277/308Win seemed like a good platform. If we could reach 3150 fps with a 150 gr .277 cal high BC copper bullet in a 24” barrel it would outperform the Fury from an AR 16” barrel at a lower peak pressure and be an excellent hunting round using more readily available brass. There is abailable a 150 gr .277 copper bullet with a G1BC of 0.710. Also Berger makes a 170 gr .277 bullet that should also work well in this elevated pressure system.Why not just make that barrel and use hybrid 277 fury cases?

It's not the action that is the problem. I'm fairly sure this has been said in this thread, but any action that can handle a magnum sized case head at standard pressure can handle a 308 sized head at 80k. The 277 fury has less bolt thrust than the 270 wsm(or a 300wm or a 7rm or a 338wm or a 338lapua etc etc. The actual force is a product of pressure and area, not just pressure.Excellent question. My thinking was use available brass that will withstand higher than SAAMI pressure. Also I don’t know that available bolt actions would handle 80000PSI. I have been testing 150 gr solids from my 308 Win and LVR powder from a 26” Savage barrel and getting 3150 fps safely with Lapua SRP brass. Without pressure equipment hard to tell where the peak pressure is, though. The nickel steel barrel in overbore cartridges should have greater throat life. The 277/308Win seemed like a good platform. If we could reach 3150 fps with a 150 gr .277 cal high BC copper bullet in a 24” barrel it would outperform the Fury from an AR 16” barrel at a lower peak pressure and be an excellent hunting round using more readily available brass. There is abailable a 150 gr .277 copper bullet with a G1BC of 0.710. Also Berger makes a 170 gr .277 bullet that should also work well in this elevated pressure system.

The only issue would be the primers piercing, but that should be able to be mitigated with small and tight tolerances on the firing pin hole and firing pin depth. Custom actions do this now.

Anything you achieve with your 70k almost rupturing brass cartridge by making the barrel longer, the fury would do even better yet if you did an apples and apples.

277 fury brass case is a 270-08. And you can buy that brass on occasion. No need to wildcat anything. You can buy the hybrid case on occasion to. You can load any bullets into them you want.

Even that 150gr SBD-2. Although you'll have to have a custom throat and run it on a medium action. The length of that bullet eats a lot of powder space in a saami chamber or short action mag.

Last edited:

Actually what you said about the action bolt thrust is very true. Wasn’t thinking of it in terms of total force which of course will vary by the square of the radius change given it’s subjected to the same pressure. Would you happen to know at what pressure a large rifle primer pocket would have to be subjected to to enlarge it sufficiently to loosen the primer and get gas escape around it?It's not the action that is the problem. I'm fairly sure this has been said in this thread, but any action that can handle a magnum sized case head at standard pressure can handle a 308 sized head at 80k. The 277 fury has less bolt thrust than the 270 wsm(or a 300wm or a 7rm or a 338wm or a 338lapua etc etc. The actual force is a product of pressure and area, not just pressure.

The only issue would be the primers piercing, but that should be able to be mitigated with small and tight tolerances on the firing pin hole and firing pin depth. Custom actions do this now.

Anything you achieve with your 70k almost rupturing brass cartridge by making the barrel longer, the fury would do even better yet if you did an apples and apples.

277 fury brass case is a 270-08. And you can buy that brass on occasion. No need to wildcat anything. You can buy the hybrid case on occasion to. You can load any bullets into them you want.

Even that 150gr SBD-2. Although you'll have to have a custom throat and run it on a medium action. The length of that bullet eats a lot of powder space in a saami chamber or short action mag.

Damn your eyes! You said it before I could. Oh well, great minds think alike and are underappreciated in their time.Barrel life should be stellar, lol

80,000 PSI and 277 Fury caliber capable semi-auto rifle is up for sale on Sig website at a jaw dropping price of $7,999.

MCX-SPEAR

First Production Run Special Edition Now Available at Select Dealers MSRP: $7999.00www.sigsauer.com

Read the reviews at the bottom of that page.

Epic.

That link didn't work but I found another one on Sig's website. However, unless I missed something, the 277 Fury isn't listed as one of the calibers and there are only two reviews at this time.

The only rifle listed for the 277 Fury is the Cross rifle, which has been discussed ad nauseum elsewhere.

Surely rather than mess about with expensive cartridges for military applications with "AR silhouette" rifles they could have just gone to bullpup chassis with 10-12 inches more barrel in the same OAL and achieved target velocities without all the bullshit?

While everyone wants 10-12” more, the target weight of the rifle becomes a concern. Add that to bullpups not enjoying a stellar reputation in the US. Maintaining a common battery of arms to rifles already in inventory is an upside- for military procurement- that cannot be ignored.

I don't but I'm quite sure it's north of 65k. Probably under 80k. I'm guessing with the steel case head this isn't as much of an issue. I guess we'll see eventually.Actually what you said about the action bolt thrust is very true. Wasn’t thinking of it in terms of total force which of course will vary by the square of the radius change given it’s subjected to the same pressure. Would you happen to know at what pressure a large rifle primer pocket would have to be subjected to to enlarge it sufficiently to loosen the primer and get gas escape around it?

even a bullpup chassis with 6.5CM or an equivalent wouldn't have achieved the desired results. I own a Desert Tech MDRX, 6.5CM out of a 20" barrel is still short of the ballistic requirements of the NGSW. Also while bullpups are great for a lot of things, and I am a proponent of them, even I will admit that they are often not as ideal as a short-barrel carbine for CQB work, and as a front-line combat rifle, it needs to be good at all things except sustained heavy fire.Surely rather than mess about with expensive cartridges for military applications with "AR silhouette" rifles they could have just gone to bullpup chassis with 10-12 inches more barrel in the same OAL and achieved target velocities without all the bullshit?

The M5 Spear won the contract because of three major factors:

1) Delivered the required ballistic results

2) The manual of arms being only minorly different from current arms means minimal retraining is required.

3) unlike some of the competing options, the new case/cartridge is designed to be made on current .308 manufacturing equipment with slight alterations to the process, instead of needing an entirely new process.

Thanks. I have avoided getting pressure measuring equipment, but I am feeling the need to do so. Like to know first hand what pressure levels are achieved with SRP brass. In the 243Win with an 80 gr bullet using SRP brass and SB6.5 powder 3700 fps from a 22” barrel is easily and safely achieved. I would like to know what is happening at the pressure side of the equation to make that possible.I don't but I'm quite sure it's north of 65k. Probably under 80k. I'm guessing with the steel case head this isn't as much of an issue. I guess we'll see eventually.

The bull pup idea seems sound at first glance. It allows for longer barrels in a short overall length rifle. Why does our military shun that design?even a bullpup chassis with 6.5CM or an equivalent wouldn't have achieved the desired results. I own a Desert Tech MDRX, 6.5CM out of a 20" barrel is still short of the ballistic requirements of the NGSW. Also while bullpups are great for a lot of things, and I am a proponent of them, even I will admit that they are often not as ideal as a short-barrel carbine for CQB work, and as a front-line combat rifle, it needs to be good at all things except sustained heavy fire.

The M5 Spear won the contract because of three major factors:

1) Delivered the required ballistic results

2) The manual of arms being only minorly different from current arms means minimal retraining is required.

3) unlike some of the competing options, the new case/cartridge is designed to be made on current .308 manufacturing equipment with slight alterations to the process, instead of needing an entirely new process.

Ya, I'd like to see something that can measure pressure available to the consumer at say.... labradar prices?Thanks. I have avoided getting pressure measuring equipment, but I am feeling the need to do so. Like to know first hand what pressure levels are achieved with SRP brass. In the 243Win with an 80 gr bullet using SRP brass and SB6.5 powder 3700 fps from a 22” barrel is easily and safely achieved. I would like to know what is happening at the pressure side of the equation to make that possible.

What bullet and how much powder? Could model it in QL or GRT.

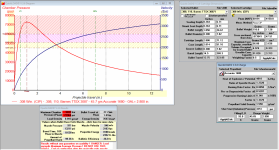

I dunno about that, even with a 65gr bullet I'm showing unsafe overpressure on both .243 win and .243 AI with quickload.Thanks. I have avoided getting pressure measuring equipment, but I am feeling the need to do so. Like to know first hand what pressure levels are achieved with SRP brass. In the 243Win with an 80 gr bullet using SRP brass and SB6.5 powder 3700 fps from a 22” barrel is easily and safely achieved. I would like to know what is happening at the pressure side of the equation to make that possible.

max safe .243 load velocity I can get with a 65gr is about 3307 at 49.4gr of StaBall 6.5

max safe .243 AI load velocity I can get with a 65gr is about 3370 at 51.0gr of StaBall 6.5

both using 22" barrels in the model.

Mainly because while it achieves the goal of being compact for a longer barrel, it is both an unfamiliar manual of arms, and requires certain training differences and approaches to close-quarters implementation. Mostly they're more difficult to sweep doors and corners with, and that's where you'll get got.The bull pup idea seems sound at first glance. It allows for longer barrels in a short overall length rifle. Why does our military shun that design?

I love mine, and do enough matches/etc that I'm comfortable doing things like that with one, but it would be a huge shift for the US military mindset, and would mean army and marine MOUT training would no longer be cross-compatible in some instances. Sometimes the design of the rifle has to take a backseat to the organization and environment in which it is used.

Attachments

Last edited:

Ya, I can't even get enough staball in a 243 case to get to 3700fps, forget pressure.I dunno about that, even with a 65gr bullet I'm showing unsafe overpressure on both .243 win and .243 AI with quickload.

max safe .243 load velocity I can get with a 65gr is about 3307 at 49.4gr of StaBall 6.5

max safe .243 AI load velocity I can get with a 65gr is about 3370 at 51.0gr of StaBall 6.5

both using 22" barrels in the model.

Mainly because while it achieves the goal of being compact for a longer barrel, it is both an unfamiliar manual of arms, and requires certain training differences and approaches to close-quarters implementation. Mostly they're more difficult to sweep doors and corners with, and that's where you'll get got.

I love mine, and do enough matches/etc that I'm comfortable doing things like that with one, but it would be a huge shift for the US military mindset, and would mean army and marine MOUT training would no longer be cross-compatible in some instances.

there is, its called pressure traceYa, I'd like to see something that can measure pressure available to the consumer at say.... labradar prices?

What bullet and how much powder? Could model it in QL or GRT.

but its not made to measure 80k accurately as it was designed around sammi, ive spoken to him on the phone with a previous project and high pressures

As popular as the lab radar is at it's price, I'm surprised people aren't proofing loads with pressure trace for roughly the same price.there is, its called pressure trace

but its not made to measure 80k accurately as it was designed around sammi, ive spoken to him on the phone with a previous project and high pressures

Last edited:

Have you tried it with SRP brass?Ya, I can't even get enough staball in a 243 case to get to 3700fps, forget pressure.

Well, I wonder, is it necessary to use 80,000PSI, build an entirely new rifle and brass out of new materials that are harder to work with and at greater expense to get 2700ft-lbs of bullet energy out of a 16” barrel? Maybe so. For years though, I have used 2 308 Win rifles, one with a 20” Douglas and another with a 20” Proof carbon barrel that push a 150 gr bullet to 2920-2950 fps generating close to 2900ft-lbs of energy. Hunted from Alaska to Africa with those rifles with never more than 1shot DRT on any animal I shot at. Have to wonder whether that load could be used in a conventional AR10 platform.As popular as the lab radar is at it's price, I'm surprised people aren't proofing loads with pressure trace for roughly the same price.

its the 3100 FPS velocity they were after, as defeating body armor and light vehicle armor depends more on velocity than projectile kinetic energy. The M5 barrels are also 14.5" SBRs, not 16" carbines, and the .277 Fury with a bimetal case loading is delivering that velocity in those barrel lengths. It's completely unlike anything else on the market. The closest thing you might be able to find is .270 AI, and that cartridge would never give you the velocities in barrels so short.Well, I wonder, is it necessary to use 80,000PSI, build an entirely new rifle and brass out of new materials that are harder to work with and at greater expense to get 2700ft-lbs of bullet energy out of a 16” barrel? Maybe so. For years though, I have used 2 308 Win rifles, one with a 20” Douglas and another with a 20” Proof carbon barrel that push a 150 gr bullet to 2920-2950 fps generating close to 2900ft-lbs of energy. Hunted from Alaska to Africa with those rifles with never more than 1shot DRT on any animal I shot at. Have to wonder whether that load could be used in a conventional AR10 platform.

Basically the army did it's usual thing of go "this is the thing we want" specifying something that was more or less an unattainable pipe dream at the time, and then someone figured out a way to actually do it.

The other reason velocity is important is the Army's M80A1/M855A1 (and the similar 6.8 projectile the spear has been seen using in testing) are aside from the penetrator component basically a copper pre-stressed controlled fracturing round that requires velocity to achieve the best terminal performance.

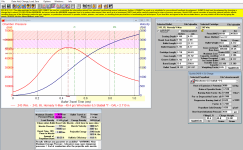

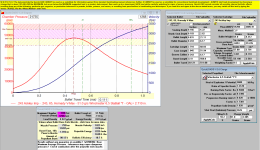

Attached is an example of what it takes to make .308 do the same velocity, in the same barrel length, with a lighter bullet than the .277 fury uses

Attachments

Last edited:

So what weight bullet is the military using in the 277 Fury?its the 3100 FPS velocity they were after, as defeating body armor and light vehicle armor depends more on velocity than projectile kinetic energy. The M5 barrels are also 14.5" SBRs, not 16" carbines, and the .277 Fury with a bimetal case loading is delivering that velocity in those barrel lengths. It's completely unlike anything else on the market. The closest thing you might be able to find is .270 AI, and that cartridge would never give you the velocities in barrels so short.

Basically the army did it's usual thing of go "this is the thing we want" specifying something that was more or less an unattainable pipe dream at the time, and then someone figured out a way to actually do it.

The other reason velocity is important is the Army's M80A1/M855A1 (and the similar 6.8 projectile the spear has been seen using in testing) are aside from the penetrator component basically a copper pre-stressed controlled fracturing round that requires velocity to achieve the best terminal performance.

Attached is an example of what it takes to make .308 do the same velocity, in the same barrel length, with a lighter bullet than the .277 fury uses

This is where I got the idea that the Army rifle has a 16”, not a 14.5”, barrel. An article published in Sniper Country. The pics are not of the full article, bu the 16” barrel is mentioned twice. Typo? Perhaps?its the 3100 FPS velocity they were after, as defeating body armor and light vehicle armor depends more on velocity than projectile kinetic energy. The M5 barrels are also 14.5" SBRs, not 16" carbines, and the .277 Fury with a bimetal case loading is delivering that velocity in those barrel lengths. It's completely unlike anything else on the market. The closest thing you might be able to find is .270 AI, and that cartridge would never give you the velocities in barrels so short.

Basically the army did it's usual thing of go "this is the thing we want" specifying something that was more or less an unattainable pipe dream at the time, and then someone figured out a way to actually do it.

The other reason velocity is important is the Army's M80A1/M855A1 (and the similar 6.8 projectile the spear has been seen using in testing) are aside from the penetrator component basically a copper pre-stressed controlled fracturing round that requires velocity to achieve the best terminal performance.

Attached is an example of what it takes to make .308 do the same velocity, in the same barrel length, with a lighter bullet than the .277 fury uses

Attachments

looks like that was written before the spec sheet was officially released. I've had the pleasure of shooting one of the few Collector SBRs that have been bought, and it is most assuredly a 14.5" barrel. There's a reason the collector versions had to go through SBR paperworkThis is where I got the idea that the Army rifle has a 16”, not a 14.5”, barrel. An article published in Sniper Country. The pics are not of the full article, bu the 16” barrel is mentioned twice. Typo? Perhaps?

even if you pinned and welded the muzzle device the suppressor attaches to, you would get 15.3" or so.

So in fact the SBR, having only a 14.5” barrel, is still able to deliver 2700 ft-lbs of bullet energy, or is that incorrect also? What weight bullet is actually shot from a 14.5” SBR? What really intrigues me about this discussion is the barrel material of the rifle. The throat has to survive extraordinary heat stress given the 80,000 PSI pressure the Fury cartridge operates at, and the rapid rates of fire potentially needed. Great info, thanks.looks like that was written before the spec sheet was officially released. I've had the pleasure of shooting one of the few Collector SBRs that have been bought, and it is most assuredly a 14.5" barrel. There's a reason the collector versions had to go through SBR paperwork

even if you pinned and welded the muzzle device the suppressor attaches to, you would get 15.3" or so.

From the civilian standpoint, the NFA restricts them to 16” barrels, but the 277Fury has ignited renewed interest in the .277 caliber, which frankly, has been ignored in the past few years in favor of the 6.5 and 7 mm. Thank you for the information you provided. I love the 308 and it will help me devise loads for it.its the 3100 FPS velocity they were after, as defeating body armor and light vehicle armor depends more on velocity than projectile kinetic energy. The M5 barrels are also 14.5" SBRs, not 16" carbines, and the .277 Fury with a bimetal case loading is delivering that velocity in those barrel lengths. It's completely unlike anything else on the market. The closest thing you might be able to find is .270 AI, and that cartridge would never give you the velocities in barrels so short.

Basically the army did it's usual thing of go "this is the thing we want" specifying something that was more or less an unattainable pipe dream at the time, and then someone figured out a way to actually do it.

The other reason velocity is important is the Army's M80A1/M855A1 (and the similar 6.8 projectile the spear has been seen using in testing) are aside from the penetrator component basically a copper pre-stressed controlled fracturing round that requires velocity to achieve the best terminal performance.

Attached is an example of what it takes to make .308 do the same velocity, in the same barrel length, with a lighter bullet than the .277 fury.

Supposedly the Spear will be released to the civilian market with a 16" barrel in .277, along with variations in .308 and 6.5CM. According to what Sig has publicly said, hunting ammunition for the cross and the spear with the bimetal case will be loaded to the same pressure spec as military, but they have obligations to the DoD to fulfill first before we'll see the stuff come to market. Same with Vortex and the XM 157 optical component.From the civilian standpoint, the NFA restricts them to 16” barrels, but the 277Fury has ignited renewed interest in the .277 caliber, which frankly, has been ignored in the past few years in favor of the 6.5 and 7 mm. Thank you for the information you provided. I love the 308 and it will help me devise loads for it.

I'm sure eventually the details will get out as someone who has access and time, and access to an x-ray diffraction gun gets a good look over of one for the material type, then you'll probably see .308 and 6.5CM "Super" using re-formed bimetal cases.

Cost-wise, for the average person the juice isn't worth the squeeze to do those wildcats unless you're trying to do something very specific with a restricted cartridge length.

especially for bolt actions, just going to a short magnum and slightly longer barrel will be much more cost effective.

the only single use-case I've found for myself is my (questionably sane) project to rebarrel and slightly re-engineer an MDRX to use .375 Raptor, which has the same case head as .308w and the same cartridge length maximum.

Your thoughts are all spot on, and I love your desire for inventiveness. What I find interesting is the barrel material that needs to be used to deal with such high pressures which equates to high temps. Right now the 33XC is an inherently accurate high capacity cartridge that, for the most part, is operating way below its potential because its barrel life is 600-700 shots in the 338 caliber when operated at full capacity using 416 stainless. The same can be said of the 338 Enabler. Cartridges opreating in the 75,000-80,000 PSI range will necessarily cause demand on primer design changes if LRP primers are to be used at those pressures. Action and bolt material design will need to change to safely contain those pressures. Finally there will need to be a change to monometal bullets as the 100+ year old cup and lead core design of bullets is simply too weak to withstand the high impact velocities anticipated. I have seen some talk of barrel material for the Fury being made out of high nickel steel, which has better heat resistance properties than 416 stainless, but is harder to machine. Necessity is the mother of invention, so we may also see changes in tooling more suited to making high nickel steel barrels and reamers to chamber them. PT&G makes “bore rider” reamer designs that allow use of greater powder charges and speed using existing brass. I know this because I happen to have a 26” 308win barrel from which I can launch a 150 gr bullet at 3140+ fps routinely and safely. I start to see signs of SRP primer flattening at 3180 fps, but no primer pocket expansion yet. I’d love to see what speed we could obtain at an 80,000PSI peak pressure from a practical 26” length barrel in 308Win with a bore rider chamber.Supposedly the Spear will be released to the civilian market with a 16" barrel in .277, along with variations in .308 and 6.5CM. According to what Sig has publicly said, hunting ammunition for the cross and the spear with the bimetal case will be loaded to the same pressure spec as military, but they have obligations to the DoD to fulfill first before we'll see the stuff come to market. Same with Vortex and the XM 157 optical component.

I'm sure eventually the details will get out as someone who has access and time, and access to an x-ray diffraction gun gets a good look over of one for the material type, then you'll probably see .308 and 6.5CM "Super" using re-formed bimetal cases.

Cost-wise, for the average person the juice isn't worth the squeeze to do those wildcats unless you're trying to do something very specific with a restricted cartridge length.

especially for bolt actions, just going to a short magnum and slightly longer barrel will be much more cost effective.

the only single use-case I've found for myself is my (questionably sane) project to rebarrel and slightly re-engineer an MDRX to use .375 Raptor, which has the same case head as .308w and the same cartridge length maximum.

barrel tech is moving forward on several fronts for the last 5+ years commercially

the next step in barrel life is ECM machined barrels and nitriding

ECM allows the use of more exotic materials and nitriding will add life but can change bore dims

both are in testing with several companies/mfg

ECM is already making pistol barrels and EMAG a german company has several deeper stroke ECM machines in use

problem with the higher pressure and monos is the shorter range accuracy

cup core is still more accurate/precise inside 1000 which is why F-class is still dominated by cup core

if the market is willing to have slightly larger groups on average (of course there are some insane mono groups), they the mono will finally take off

plus for the guys who "shoot steel", monos dont splash so spotting is much harder at range

the next step in barrel life is ECM machined barrels and nitriding

ECM allows the use of more exotic materials and nitriding will add life but can change bore dims

both are in testing with several companies/mfg

ECM is already making pistol barrels and EMAG a german company has several deeper stroke ECM machines in use

problem with the higher pressure and monos is the shorter range accuracy

cup core is still more accurate/precise inside 1000 which is why F-class is still dominated by cup core

if the market is willing to have slightly larger groups on average (of course there are some insane mono groups), they the mono will finally take off

plus for the guys who "shoot steel", monos dont splash so spotting is much harder at range

277 fury brass case is a 270-08. And you can buy that brass on occasion. No need to wildcat anything. You can buy the hybrid case on occasion to. You can load any bullets into them you want.

Even that 150gr SBD-2. Although you'll have to have a custom throat and run it on a medium action. The length of that bullet eats a lot of powder space in a saami chamber or short action mag.

Regardless of the specifics, the .277 Fury is limited to similar case capacity as any other 308 based cartridge. To get that kind of pressure out of a small cartridge, they must be using a very specific powder. I wonder what it is.

I mean, I posted a .308 Win achieving the stated velocities from the stated barrel length, and it was about 10-15% below the pmax of 80k. so my guess would be something with a density and burn rate comparable to Accurate 1680Regardless of the specifics, the .277 Fury is limited to similar case capacity as any other 308 based cartridge. To get that kind of pressure out of a small cartridge, they must be using a very specific powder. I wonder what it is.

Unless the Army changed things up very recently, theits the 3100 FPS velocity they were after, as defeating body armor and light vehicle armor depends more on velocity than projectile kinetic energy. The M5 barrels are also 14.5" SBRs, not 16" carbines, and the .277 Fury with a bimetal case loading is delivering that velocity in those barrel lengths. It's completely unlike anything else on the market. The closest thing you might be able to find is .270 AI, and that cartridge would never give you the velocities in barrels so short.

Basically the army did it's usual thing of go "this is the thing we want" specifying something that was more or less an unattainable pipe dream at the time, and then someone figured out a way to actually do it.

The other reason velocity is important is the Army's M80A1/M855A1 (and the similar 6.8 projectile the spear has been seen using in testing) are aside from the penetrator component basically a copper pre-stressed controlled fracturing round that requires velocity to achieve the best terminal performance.

Attached is an example of what it takes to make .308 do the same velocity, in the same barrel length, with a lighter bullet than the .277 fury uses

And yes, M855A1/M80A1 require a certain velocity threshold to achieve reliable fragmentation… but that’s true of any expanding or fragmenting bullet. And not only is the velocity threshold for M855A1 lower than M855, but it is much more reliable in its fragmentation as well, not being depending on fleet yaw. The penetrator pushing into the copper has a similar effect as the polymer tips on TMKs, or tipped TSXes.

Edit: correction, it is not being called the M7 instead of M5, due to copyright issues.

Last edited:

I think. 277 Fury is an interesting cartridge, and I see a lot of potential with bi-metal cases.

However, I think 277 Fury is a better choice for mag fed gas guns. It seems like there are easier options for bolt actions, unless you absolutely positively want those kinds of velocities from a short action.

For those interested:

The normal brass 277 Fury attains 2600 FPS from a 13” barrel

The bi-metal attains 2900 fps from a 13” barrel!

I didn’t hear in this video what grain the bullets were. I may have missed it. It should be somewhere in the 135gr - 150gr range. Impressive velocities from such a short barrel.

However, I think 277 Fury is a better choice for mag fed gas guns. It seems like there are easier options for bolt actions, unless you absolutely positively want those kinds of velocities from a short action.

For those interested:

The normal brass 277 Fury attains 2600 FPS from a 13” barrel

The bi-metal attains 2900 fps from a 13” barrel!

I didn’t hear in this video what grain the bullets were. I may have missed it. It should be somewhere in the 135gr - 150gr range. Impressive velocities from such a short barrel.

Last edited:

Will have to disagree with you a bit. For hunting the right monos are quite accurate inside 1000 yds lethality is way better. BCs can beat all cup&core bullets with in given weight. I can’t elaborate any more than that here.barrel tech is moving forward on several fronts for the last 5+ years commercially

the next step in barrel life is ECM machined barrels and nitriding

ECM allows the use of more exotic materials and nitriding will add life but can change bore dims

both are in testing with several companies/mfg

ECM is already making pistol barrels and EMAG a german company has several deeper stroke ECM machines in use

problem with the higher pressure and monos is the shorter range accuracy

cup core is still more accurate/precise inside 1000 which is why F-class is still dominated by cup core

if the market is willing to have slightly larger groups on average (of course there are some insane mono groups), they the mono will finally take off

plus for the guys who "shoot steel", monos dont splash so spotting is much harder at range

Prove it. That’s right, you can’t. So please leave don’t state unfounded opinions as facts.“… inside 1000 yds lethality is way better.“

On animals, I can. For years, probably 10-11, I hunted with Sierra 180 gr Game Kings, shot from both the 308 Win and 300 WSM mostly African plains game, and the reality is that there was not a single hunt I went on that I did not have at least one issue with the way those bullets performed on the game, and these were bullets presumably designed to hunt with, not a fragile target bullet like the Match King. Accuracy was never an issue. Double lung shots at 400 yds were variably lethal on Wildebeests, in one glaring instance we chased a Black Wildebeest FOR A MILE after having received a double lung shot at 360 yds that had an exit hole 2.5-3 inches wide. It was still alive when we caught up to it and breathing heavily. Since I have been using lathe turned c110 copper bullets have never had to chase a single animal more than 45 yds, but 90% were DRT regardless of the type of chest impact or the angle of such impact. That includes Alaskan Coastal Black Bear. The last African hunt I did with those bullets I got 7 animals in 7 hits and none went more than 25 yds with a150 gr bullet using a 20” 308 Win. Prong Horn Antelope hunting with a 243 Win using experimental 75 gr bullets have been 100% lethal 1 shot affairs out to 450+ yds even on running animals. Maintaining <1MOA dispersion at 400 yds is easy and the BC of the 150 gr bullet I use now is greater than the 175 gr SMK. Have never shot a human, and hope to God I never have to, so I can’t attest to the comparative lethality on that target.Prove it. That’s right, you can’t. So please leave don’t state unfounded opinions as facts.

Last edited:

I'd suggest posting some pics in the hunting threads, not many from folks that get to hunt in africa so it'd spice up the usual deer shotsOn animals, I can. For years, probably 10-11, I hunted with Sierra 180 gr Game Kings, shot from both the 308 Win and 300 WSM mostly African plains game, and the reality is that there was not a single hunt I went on that I did not have at least one issue with the way those bullets performed on the game, and these were bullets presumably designed to hunt with, not a fragile target bullet like the Match King. Accuracy was never an issue. Double lung shots at 400 yds were variably lethal on Wildebeests, in one glaring instance we chased a Black Wildebeest FOR A MILE after having received a double lung shot at 360 yds that had an exit hole 2.5-3 inches wide. It was still alive when we caught up to it and breathing heavily. Since I have been using lathe turned c110 copper bullets have never had to chase a single animal more than 45 yds, but 90% were DRT regardless of the type of chest impact or the angle of such impact. That includes Alaskan Coastal Black Bear. The last African hunt I did with those bullets I got 7 animals in 7 hits and none went more than 25 yds with a150 gr bullet using a 20” 308 Win. Prong Horn Antelope hunting with a 243 Win using experimental 75 gr bullets have been 100% lethal 1 shot affairs out to 450+ yds even on running animals. Maintaining <1MOA dispersion at 400 yds is easy and the BC of the 150 gr bullet I use now is greater than the 175 gr SMK. Have never shot a human, and hope to God I never have to, so I can’t attest to the comparative lethality on that target.

Prove it. That’s right, you can’t. So please leave don’t state unfounded opinions as facts.

There is a video on UTube called “Badlands 150 Bulldozer vs Blue Wildebeest”. The shot was from a 20” 308 Win at 482 yds, MV=2950fps, and if you expand the image or look at it on a larger computer screen you can see a bullet splash about 100 yds beyond the animal.I'd suggest posting some pics in the hunting threads, not many from folks that get to hunt in africa so it'd spice up the usual deer shots

More detail would be greatly appreciated...FN is displaying a bimetal cartridge at Shot in 6.5 with 180grainers.

Does anyone happen to have any of those hybrid cases lying around that have been shot and are gathering dust? I would pay the shipping to have them sent to me. I would like to study 20 of them or so.

i second that. More info pleaseMore detail would be greatly appreciated...

Brass availability, gun availability and PRICE?FN is displaying a bimetal cartridge at Shot in 6.5 with 180grainers.

Last I seen the spec it was a 140gr. That was the original spec written.So what weight bullet is the military using in the 277 Fury?

140gr bullet at 3000+fps was the spec.

Has it changed though? That I don’t know.

150 was what i readLast I seen the spec it was a 140gr. That was the original spec written.

140gr bullet at 3000+fps was the spec.

Has it changed though? That I don’t know.

Like I said...that's the original spec.150 was what i read

I have the original bullet drawing. 3000fps+ and the bullet was a solid projectile.

Now did the spec. change...that I don't know. No I will not post the drawing. Don't ask.

The spec was laid down and it was up to the manufacturers to come up with a cartridge design on they're own.

So anyone following this thread needs to ask themselves a few questions.

At these pressures and velocities.....

What is your accuracy requirement?

What is your expected barrel life?

How often do you plan on cleaning the barrel?

At these pressures and velocities.....

What is your accuracy requirement?

What is your expected barrel life?

How often do you plan on cleaning the barrel?

Similar threads

- Replies

- 33

- Views

- 5K

- Replies

- 84

- Views

- 10K

- Replies

- 246

- Views

- 43K