I have a feeling this is a thread that will hang around forever. Because it shows, that yes, you DO indeed need to clean your centerfire suppressor. Not just your takedown 22 cans.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Suppressors Do you clean your suppressor?

- Thread starter parshal

- Start date

People keep saying CLR. Do they mean calcium lime rust, or CLP?

^^What he said.^^ The actual household CLR (calcium lime rust) liquid.The household CLR

^^What he said.^^ The actual household CLR (calcium lime rust) liquid.

I soaked my titanium .22 baffles in CLR for about 2 hours, and was amazed how easy they were to just wipe clean afterwards. A couple of baffles still had some lead buildup on their face, but a couple of minutes with a pick took care of that.

I can see using CLR in a sealed can, and it would be easy to wipe the blast and exit baffles, but how would you get to the pasty grime on the interior baffles?

For those folks that are using CLR to clean their suppressors; what ratio of water do you use with the mixture?

Do you use the CLR full strength, equal amount with water or another ratio?

Do you use the CLR full strength, equal amount with water or another ratio?

That’s why I use the ultrasonic cleaner. A few times in the US with Simple Green afterwards works really well to finish the job on my sealed can....

I can see using CLR in a sealed can, and it would be easy to wipe the blast and exit baffles, but how would you get to the pasty grime on the interior baffles?

I run it in the US for a couple cycles, let it set for a bit, then shake it up really well with the can about 3/4 full of simple green. A few cycles of that and everything looks clean inside.

For those folks that are using CLR to clean their suppressors; what ratio of water do you use with the mixture?

Do you use the CLR full strength, equal amount with water or another ratio?

Full strength.

That’s a good question and one that I cannot answer, because I’m not a chemist. I can tell you that the “dip” is hydrogen peroxide and vinegar and is specifically used to dissolve lead, especially in rimfire cans. CLR is another acid altogether and I am not sure that it dissolves lead. Most of the buildup in center fire cans is carbon and not lead.Why is lead dissolved in CLR any safer to dispose of than lead dissolved in the "dip"?

That’s why I use the ultrasonic cleaner. A few times in the US with Simple Green afterwards works really well to finish the job on my sealed can.

I run it in the US for a couple cycles, let it set for a bit, then shake it up really well with the can about 3/4 full of simple green. A few cycles of that and everything looks clean inside.

The US doesn't hurt the suppressor's finish?

Why is lead dissolved in CLR any safer to dispose of than lead dissolved in the "dip"?

I don't think CLR actually dissolves the lead. I do think it will help loosen the lead chunk's bond to the baffles. Especially the lead that is mixed in with carbon.

I think this was already discussed earlier in this thread. However, I’ll regurgitate what I know and what I remember was said:The US doesn't hurt the suppressor's finish?

I only have the one can. It’s titanium with some sort of hardened black finish. I shoot mine 100% of the time with a mirage cover on it and I clean mine by filling with CLR and soaking for a few hours to a day, or overnight. Then I shake and rinse with water. Then multiple trips through the ultrasonic cleaner with full strength simple green, with various soak periods in there.

At the end, I make sure that shake it vigorously with about 3/4 filled with simple green, rinse and shake with water and dry. The finish doesn’t seemed harmed in any way, even with years of this treatment. There is some minor discoloration of the the finish, but since mine lives under wraps, it doesn’t bother me.

Harbor freight ultra sonic with CLR cleaned my OSS Rad 22 baffles like new. but I dont think ill clean my center fire Omega.... I'll just keep firing it till it fails....

Man, I wish I had your money and patience to throw at another can. Waiting till it fails for sake of not cleaning (which is an easy process) is one you may regret. My Omega after 4,000+ rounds gained 4oz. Doesn’t seem like much, until you throw it on an SBR.

One week soak with some solvent will hurt nothing and keep the build up down. Not chastising, just suggesting.

That’s why I use the ultrasonic cleaner. A few times in the US with Simple Green afterwards works really well to finish the job on my sealed can.

I run it in the US for a couple cycles, let it set for a bit, then shake it up really well with the can about 3/4 full of simple green. A few cycles of that and everything looks clean inside.

Full strength.

That’s a good question and one that I cannot answer, because I’m not a chemist. I can tell you that the “dip” is hydrogen peroxide and vinegar and is specifically used to dissolve lead, especially in rimfire cans. CLR is another acid altogether and I am not sure that it dissolves lead. Most of the buildup in center fire cans is carbon and not lead.

Here is the list of ingredients in CLR. I'm not a chemist but reading this suggests that there might be a problem with lead in solution. On the other hand, the Safety Data Sheet recommends taking the used contents to a HAZMAT disposal station.

I've been reluctant to use the DIP because of the hazards. Even if I did wear proper PPE with the DIP I could just imagine the questions for a HAZMAT disposal station with the DIP. On the other hand, if I took the CLR along with the Safety Data Sheet and told them it is used CLR, perhaps that would avoid pesky little questions.

Here is the Safety Data Sheet.

Ingredients...

| Water | Dilutent: CAS #7732-18-5 |

| + MORE DETAILS |

| Dilutent: CAS #7732-18-5. Reverse Osmosis (RO) is a water treatment process that removes contaminants from water by passing the water through a membrane, (filter), where contaminants are filtered out yielding more pure quality water. | |||

| Lactic Acid | Chelating Agent: CAS #79-33-4. |

| + MORE DETAILS |

| Chelating Agent: CAS #79-33-4. Lactic acid is found in many yogurts and cheeses. It is also produced in the muscles during intense activity. Commercially, it is produced by fermentation of simple sugars. In cleaning producs it functions as a chelating agent; a compound that makes metals more soluble in water. As part of the EPA Safer Choice Program, it has been evaluated and determined to be safer than traditional chemical ingredients | |||

| Lauramine Oxide | Surfactant: CAS #1643-20-5. |

| + MORE DETAILS |

| Surfactant: CAS #1643-20-5. Used in cleaners to modify the surface tension of water, to aid in even spreading and to allow mixing with oil and dirt so that they can be rinsed away; it is included in many soaps, detergents, and several groups of antiseptics. As part of the EPA Safer Choice Program, it has been evaluated and determined to be safer than traditional chemical ingredients. | |||

| Gluconic Acid | Chelating Agent: CAS #526-95-4. |

| + MORE DETAILS |

| Chelating Agent: CAS #526-95-4. This ingredient is an acid formed from the sugar glucose, which naturally occurs in fruit, honey and wine. It is a chelating agent; a compound that makes metals more soluble in water. As part of the EPA Safer Choice Program, it has been evaluated and determined to be safer than traditional chemical ingredients. | |||

| Tripropylene Glycol n-Butyl Ether | Solvent: CAS #55934-93-5. |

| + MORE DETAILS |

| Solvent: CAS #55934-93-5. Used to slow down the evaporation of many liquid products including oven cleaners and inks for ball-point and felt-tip pens. It is very effective at absorbing organic material. As part of the EPA Safer Choice Program, it has been evaluated and determined to be safer than traditional chemical ingredients. California CPRKA Designated Lists (12) US NTP Reproductive or Developmental Toxicants. https://ntp.niehs.nih.gov/publications/monographs/index.html (16) California NLs. https://oehha.ca.gov/water/notification-levels-chemicals-drinking-water (18) California TACs. https://ww3.arb.ca.gov/toxics/id/taclist.htm (20) California Non-Cancer Hazards. https://oehha.ca.gov/air/general-in...-chronic-reference-exposure-level-rel-summary | |||

| Yellow No. 5 | Colorent: CAS #1934-21-0. |

| + MORE DETAILS |

| Colorent: CAS #1934-21-0. A synthetic lemon yellow dye used all over the world, primarily as food coloring. As part of the EPA Safer Choice Program, it has been evaluated and determined to be safer than traditional chemical ingredients. | |||

| Acid Blue No.1 | Colorent: CAS #3844-45-9. |

| + MORE DETAILS |

| Colorent: CAS #3844-45-9. A blue dye used for foods and other substances. As part of the EPA Safer Choice Program, it has been evaluated and determined to be safer than traditional chemical ingredients. |

I know this is old but playing devil's advocate here, how would the EPA know?It should be said that this mixture creates Lead Acetate, which is very toxic. Do NOT dump that shit down the drain unless you want a visit from the EPA.

BTW, I do use the DIP solution on my Sparrow and if you pour it out in a large pan in the sun it will evaporate.

What do you do with the solid residue afterwards?

regardless of the EPA or not, its a shitty thing to do.I know this is old but playing devil's advocate here, how would the EPA know?

I know this is old but playing devil's advocate here, how would the EPA know?

I work in a highly regulated industry and the EPA is one of many that will crawl up your ass about stuff you didn’t even know you did.

You might argue small fish, large pond so on and so on which is probably true, but the fact remains, they can trace just about anything they want back to its source given enough time and resources.

Ultimately people are going to do what they want, all I’m saying is you don’t want to be on the receiving end of that knock...

Edited to add: regardless, hopefully you have enough moral integrity to not consciously hurt the environment.

Last edited:

This. Whether you are on a municipal water system or a well, it’s a really shitty thing to do. You are literally poising the water system. It’s just not a good idea.regardless of the EPA or not, its a shitty thing to do.

Stays in the pan. It's not like a clean a suppressor every week. I maybe clean the Sparrow 8-12 times a year. Thinking about, I need to clean it now.What do you do with the solid residue afterwards?

Thanks, I mean it works and works well with minimal mechanical cleaning. If a person doesn't feel comfortable then don't use this method. I have reduced the amount I use compared to when I first started.Good information.

Sitting overnight it will take my Sparrow from this...

to this. Keep in mind that I did knock off all the heavy deposits from the photo above.

Thanks, I mean it works and works well with minimal mechanical cleaning. If a person doesn't feel comfortable then don't use this method. I have reduced the amount I use compared to when I first started.

View attachment 7313193

Sitting overnight it will take my Sparrow from this...

View attachment 7313196

to this. Keep in mind that I did knock off all the heavy deposits from the photo above.

View attachment 7313197

Is that the CLR or the DIP?

I clean mine every 6 months with CLR.I sent an Ultra 7 to TBAC to remove the insert to go from direct thread to CB mount. When I weighed the box I thought to myself "that's pretty heavy". I got a call from them the day they received it and they said it should be cleaned asit was nearly 4 oz. heavy. I've never cleaned it and have, maybe, 2000 rounds down it. It's probably more like 1200. No H1000 which was the first question asked of me. In any case, they said it might take a few weeks to get it thoroughly cleaned. Luckily, I don't need it for a while.

The rest of my cans can all be taken apart so I decided to clean them, too. I was easily able to take apart the two rimfire ones but the other two center fire (Lane) are a bugger. I've got them soaking in CLR now.

I searched around the net and I see lots of people saying you don't need to clean a centerfire can. Then, there are others that do regularly. Just curious what you folks here are doing. Are you regularly cleaning your centerfire cans?

Ok... I'm going to share a story. I used to be on the side of many here with the theory of "just shoot it clean". That was until my Elite Iron can started blowing big chunks out and I investigating inside with my bore scope. I called Dale at EI and he made the following recommendation. 3 day soak and rinse with hot water. That's it! Everything comes out and it leaves the internals looking like new again. Be very careful lowering the can into the chemical though!! The "tube" like shape of suppressors cause a spurt of liquid to shoot up when lowered in. Found that out the hard way! It's not fun in your eye. Now I put the can in first and then fill when possible. I clean my cans once a year.

Vinegar on its own is great for cleaning coffee pots and hard water stains on glassware, but not so much for cleaning carbon out of suppressors.

Vinegar (industrial grade) is all I use and it works great, though I still have to apply some elbow grease if I want them spic-n-span clean. It costs about $2/gallon at the hardware stor.

This photo was taken after about cleaning #6 on this can:

Last edited:

Any update on BoreTech’s suppressor cleaner they were looking at releasing in April before the ‘rona done messed everything up?

Any update on BoreTech’s suppressor cleaner they were looking at releasing in April before the ‘rona done messed everything up?

Nope! I reached out to them a few weeks ago, never heard anything back

Note: this post concerns mainly rimfire use (lead) and safety.

I own the same can as you, and shoot rimfire and centerfire through it. What does just vinegar + lead make? My google-fu is weak on this one.

I know the DIP (hydrogen peroxide + vinegar + lead) produces lead acetate, which readily absorbs right through your skin and lungs, and even through some glove materials (I forget which ones).

On another note lash says above that CLR is phosphoric acid. What does phosphoric acid + lead produce? Being a non-chemist, google suggests: Lead + Phosphoric Acid = Dihydrogen + Lead(II) Phosphate

Lead phosphate seems to be not good for you, especially through the air if heated.

Of course, raw lead is not good for you either, but It’s a matter of safe handling. A chunk of lead has a much harder time entering one’s body than airborne lead or lead in liquid. Unless that lead hits you at a decent FPS

Last edited:

I sent an Ultra 7 to TBAC to remove the insert to go from direct thread to CB mount. When I weighed the box I thought to myself "that's pretty heavy". I got a call from them the day they received it and they said it should be cleaned asit was nearly 4 oz. heavy. I've never cleaned it and have, maybe, 2000 rounds down it. It's probably more like 1200. No H1000 which was the first question asked of me. In any case, they said it might take a few weeks to get it thoroughly cleaned. Luckily, I don't need it for a while.

The rest of my cans can all be taken apart so I decided to clean them, too. I was easily able to take apart the two rimfire ones but the other two center fire (Lane) are a bugger. I've got them soaking in CLR now.

I searched around the net and I see lots of people saying you don't need to clean a centerfire can. Then, there are others that do regularly. Just curious what you folks here are doing. Are you regularly cleaning your centerfire cans?

pressure washer if its strippable, been using sound mods for 12 or so years any that cant be stripped soak in any decent descaler job done. probably can just use strong white vinegar, never tried

@JC0352 Heard back from BoreTech. Appears Covid did slow them down, hopefully some time this year.

“

ABSOLUTELY, we will be releasing the suppressor cleaner later this year.

CV-19 certainly slowed things down and put us months behind schedule.

If you are not already signed up for our e-mail newsletter, please do as we will be sending out an e-mail as soon as it is available.“

“

ABSOLUTELY, we will be releasing the suppressor cleaner later this year.

CV-19 certainly slowed things down and put us months behind schedule.

If you are not already signed up for our e-mail newsletter, please do as we will be sending out an e-mail as soon as it is available.“

Last edited:

Okay, I have to clear a couple things in your post up for other readers. First off, this thread was started to specifically address centerfire cans only. Most centerfire cans do not build up much lead at all since the majority of projectiles used in centerfire (for long range precision rifles) are jacketed. The primary buildup issue in centerfire cans is hard carbon deposits.Note: this post concerns mainly rimfire use (lead) and safety.

I own the same can as you, and shoot rimfire and centerfire through it. What does just vinegar + lead make? My google-fu is weak on this one.

I know the DIP (hydrogen peroxide + vinegar + lead) produces lead acetate, which readily absorbs right through your skin and lungs, and even through some glove materials (I forget which ones).

On another note lash says above that CLR is phosphoric acid. What does phosphoric acid + lead produce? Being a non-chemist, google suggests: Lead + Phosphoric Acid = Dihydrogen + Lead(II) Phosphate

Lead phosphate seems to be not good for you, especially through the air if heated.

Of course, raw lead is not good for you either, but It’s a matter of safe handling. A chunk of lead has a much harder time entering one’s body than airborne lead or lead in liquid. Unless that lead hits you at a decent FPS

As such, the DIP does not work as well on centerfire cans as it does for rimfire, where the primary fouling is lead-based. Many people are not bothering to read the thread and are throwing in their solutions for rimfire cans. That’s all great except they are different and should be treated differently.

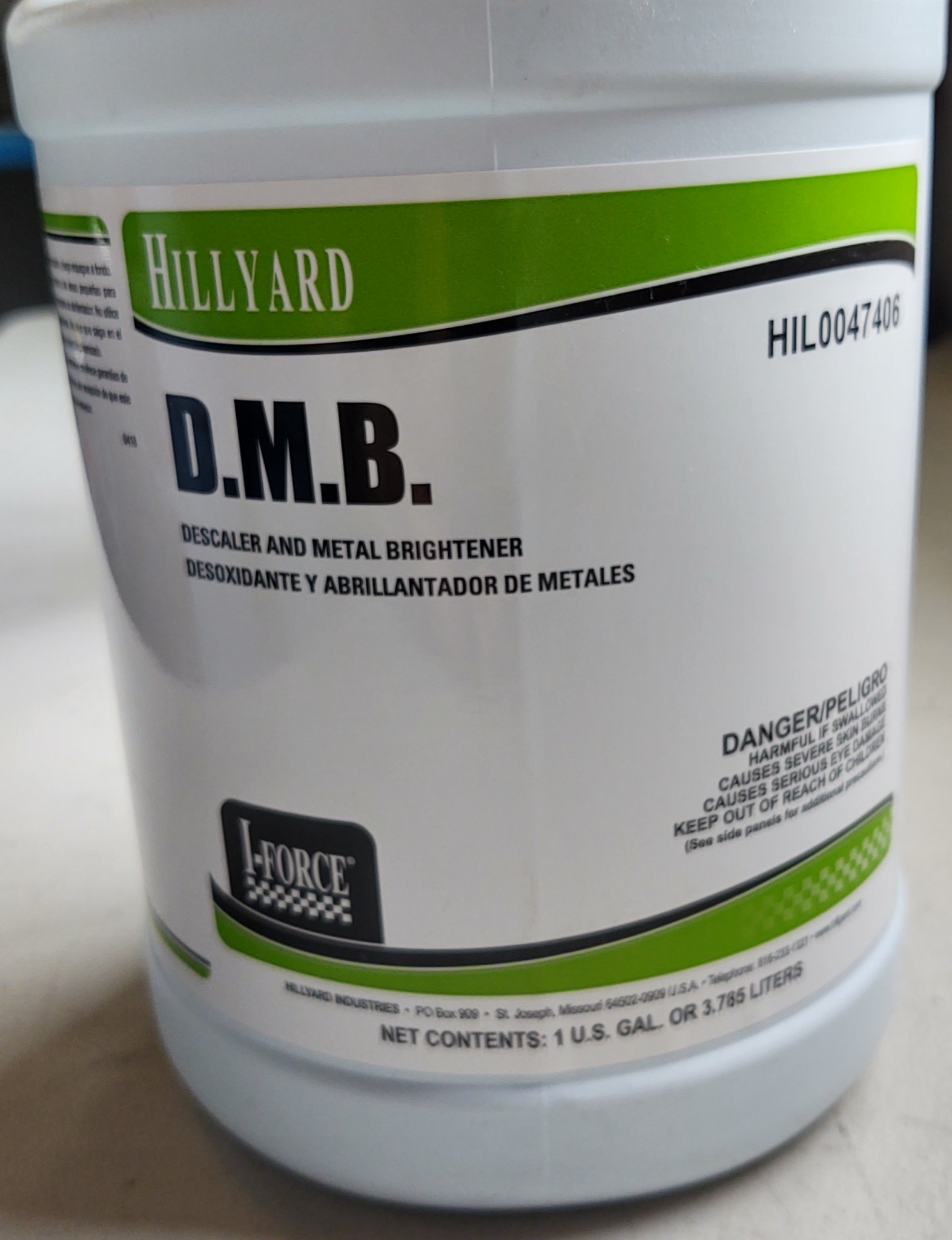

Secondly, I did not say that CLR is phosphoric acid based. My post above was discussing a previous poster’s use of DMB metal descaler, which is phosphoric acid based. CLR, per the SDS info posted earlier in this thread, uses lactic acid and glycemic acid as the base chelating chemicals. These have been determined to be safer to use than many other industrial grade acids.

As always, when dealing with chemicals and cleaning products, it is highly advisable that one wear proper protective gear and not drink, sniff the fumes or apply to your skin. Dispose of any used product properly. Reading the side of the bottle will tell you that if you didn’t already know this.

I got on a trust with some family members and we purchased 2x SRT 9" .30 cal cans at the same time. I have used mine for over 10,000 rounds and I'd be surprised if the other one has more than 500 through it. They weigh 7.8 oz different (mine heavier). I used to take it apart (not supposed to be able to but I made a tool) every 500 rounds to clean it but around 5-6k rounds ago I let it go long enough I couldn't disassemble it (carbon locked) and decided just to leave it alone.

Recently I tried soaking it in CLR for about a week and it did remove roughly an ounce of carbon from the can but there's still a 6-7oz in there. I was looking into a pump setup maybe to force a continual flow of CLR through the can and just let it sit for a month in a couple gallons of the stuff.

Recently I tried soaking it in CLR for about a week and it did remove roughly an ounce of carbon from the can but there's still a 6-7oz in there. I was looking into a pump setup maybe to force a continual flow of CLR through the can and just let it sit for a month in a couple gallons of the stuff.

Recently I tried soaking it in CLR for about a week and it did remove roughly an ounce of carbon from the can but there's still a 6-7oz in there. I was looking into a pump setup maybe to force a continual flow of CLR through the can and just let it sit for a month in a couple gallons of the stuff.

Based on reading the other posts here you will probably have to soak and repeat soak numerous times to get that much gunk out. I would think filling the can up with cleaner, soaking for a day, dumping it out, and repeat until clean would be a lot easier and cheaper than trying to make a pump system.

As I posted earlier, I’ve had good success with one initial overnite soaking in CLR, followed by a few sessions of alternating ultrasonic cleaning and soaking in simple green. Using Simple green full strength in the US cleaner. The ultrasonic cleaner helps by breaking up the softened chunks and particles of carbon. About a week of this and there’s nothing left.I got on a trust with some family members and we purchased 2x SRT 9" .30 cal cans at the same time. I have used mine for over 10,000 rounds and I'd be surprised if the other one has more than 500 through it. They weigh 7.8 oz different (mine heavier). I used to take it apart (not supposed to be able to but I made a tool) every 500 rounds to clean it but around 5-6k rounds ago I let it go long enough I couldn't disassemble it (carbon locked) and decided just to leave it alone.

Recently I tried soaking it in CLR for about a week and it did remove roughly an ounce of carbon from the can but there's still a 6-7oz in there. I was looking into a pump setup maybe to force a continual flow of CLR through the can and just let it sit for a month in a couple gallons of the stuff.

The cheap chicom harbor freight 2.5 liter ultrasonic cleaner for $70 is worth it and is all you need to do this. It easily fits my 9” can.

If you want to do a pump system, then I imagine a PC watercooling or fish tank pump with a very large reservoir of CLR. A Tupperware container with the lid, cut some holes in the lid, one for a tight fit to hold the can on its end as the return then another for tubing to feed the pump. A stainless fitting for the can could be an issue. Then just let it run until forever.

You could get fancy and do a whole second container that it would draw cleaner solution from while the can deposits into the first with the sediment and debris.

Not sure I would try and make a sealed system. If this creates any gasses and pops a line you could wind up with a giant mess.

You could get fancy and do a whole second container that it would draw cleaner solution from while the can deposits into the first with the sediment and debris.

Not sure I would try and make a sealed system. If this creates any gasses and pops a line you could wind up with a giant mess.

If you want to do a pump system, then I imagine a PC watercooling or fish tank pump with a very large reservoir of CLR. A Tupperware container with the lid, cut some holes in the lid, one for a tight fit to hold the can on its end as the return then another for tubing to feed the pump. A stainless fitting for the can could be an issue. Then just let it run until forever.

You could get fancy and do a whole second container that it would draw cleaner solution from while the can deposits into the first with the sediment and debris.

Not sure I would try and make a sealed system. If this creates any gasses and pops a line you could wind up with a giant mess.

Just tossing ideas out here.

A peristaltic pump would be the best bet here in term of chemical resistance.

You‘re not looking for a lot of pressure or flow, just to keep the solution moving and agitated.

For filtration, think along the lines of a siphon like an aquarium filter with batting to capture the carbon.

I emailed BoreTech, and specifically asked if the C4 was safe for Inconel (the baffles in my YHM 3300-Ti3 are heat treated 718 Inconel), and I received a response that it is. He also said quote "Check us out later this year as we actually have a suppressor cleaning system coming out that has specifically formulated cleaners and devisces to make cleaning suppressors super easy and effective."Thanks for putting this up. Its obvious from your test that the C4 is the best cleaner. The question is, is it safe to use on the Omega? I saw in a previous post you were going to use the boretech on your omega, but Silencerco only recommended Hoppes and Mineral Spirits. Based on my soak in mineral spirits for 2+ days and your observations with Hoppes, Silencerco's recommendation is useless. What now, just accept the risk and try the C4?

I also took the excellent advice from earlier in this thread, and weighed my suppressor (only had 150 rds through it at this point) for baseline. My mistake was weighing it in lbs to one decimal point. Weighed 1.0 lbs before putting 50 rds through it, and weighed 1.1 lbs after. I then switched the kitchen scale to grams...so I'll do a clean withe the C4 carbon remover when it comes in, and do a new baseline weight measurement (mass, actually) in grams.

How long should I leave it in...6 hours, with swishing the stuff around every hour or so?

How long should I leave it in...6 hours, with swishing the stuff around every hour or so?

The YHM manual also says to use a mix of mineral spirits and transmission fluid (not kidding). Thank God I read this thread.Thanks for putting this up. Its obvious from your test that the C4 is the best cleaner. The question is, is it safe to use on the Omega? I saw in a previous post you were going to use the boretech on your omega, but Silencerco only recommended Hoppes and Mineral Spirits. Based on my soak in mineral spirits for 2+ days and your observations with Hoppes, Silencerco's recommendation is useless. What now, just accept the risk and try the C4?

I let my silencerco harvester soak in CLR twice for about an hour at a time. And I was amazed how fast it cleaned some of the carbon out. And it didn't damage the suppressor in any way.

For my Omega, the C4 did a great job of losening the carbon, but not getting it out. I had to use a pick or brush to get it out. The ultrasonic though, the carbon came out in the solution and deposited itself at the bottom of the jar. As long as you don't mind your suppressor sleeve potentially unscrewing, I would do both.

I just ordered the same ultra sonic cleaner. Tired of waiting for Boretech to release their can cleaner.

I went to the range today with my new Harvester can. Shot them back to back and my Omega doesnt even sound close to the suppression that the Harvester is getting. I do remember the Omega being quieter.

Gonna do the C4/Mineral Spirits soak with the ultra sonic for a weeks time and see if this bitch loses some weight. If not, I’m gonna roll the dice with some CLR (inside only) soak for 30 minutes.

Soaking in CLR for an hour or so... gonna see how it does. Its bubbling like a mofo....

Similar threads

- Replies

- 9

- Views

- 491

- Replies

- 17

- Views

- 717

- Replies

- 31

- Views

- 2K

- Replies

- 17

- Views

- 1K