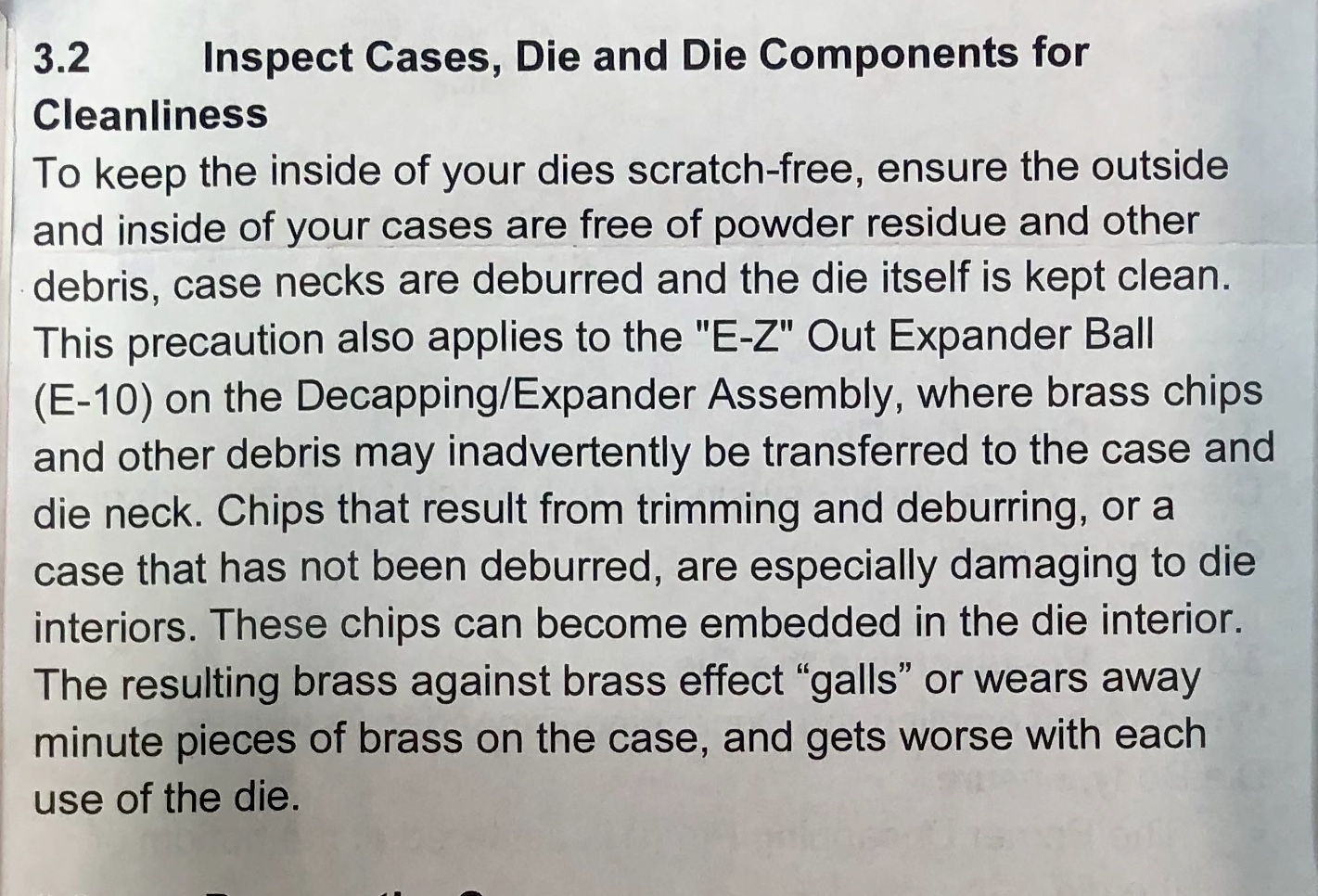

Ordered a custom honed Forster BR full length sizer die. Instruction manual has two comments about brass shavings from trimming, chamfering or deburring imbedding in the steel die (or sizing ball) and causing galling and presumably a sticky case situation or a skew neck (excessive runout).

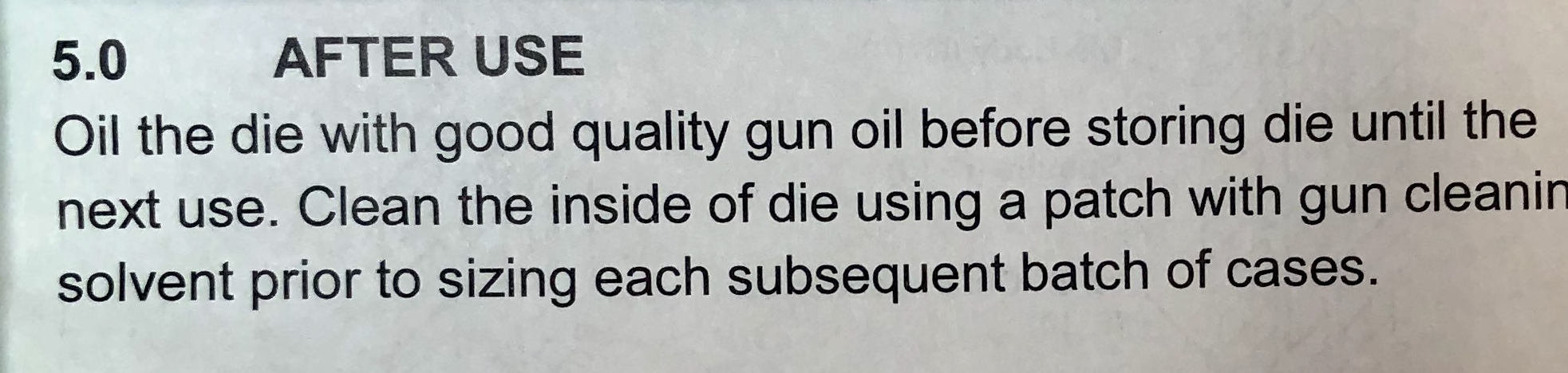

Followed by cleaning instructions that hint at removing brass from the inside of the die:

Do you guys use copper remover (barrel cleaning solution) every time after finishing the sizing of a batch of brass?

I have never done that before, so curious what your opinions are.

Followed by cleaning instructions that hint at removing brass from the inside of the die:

Do you guys use copper remover (barrel cleaning solution) every time after finishing the sizing of a batch of brass?

I have never done that before, so curious what your opinions are.

Last edited: