I had touched on using a silicone grease I "borrowed" from work in a previous thread and finally got the oppurtunity to do a test today.

I tried 3 different ammos - CCI Standard Velocity, Fed bulk pack, CCI blazer, and then used a group of Wolf MT as a comparison. For todays trial, I shot 50 and 100 yards, the 200 yard targets below were from another session.

I've done alot of lube testing using the different lubes on different ammos. Just going on group sizes alone without having a complicated recipe, Moly or graphite spray lube rated #1, Bowstring wax (beeswax) being #2, and Alox bullet lube being #3. Another 10 types of lubes / waxes were tested 22 ammo lubrication

The drawback to the moly or graphite spray is that it was almost as pricey as to just purchase match ammo and time consuming to spray on a large amount of ammo. I just found out today that the Alox bullet lube (which has the consistancy of ear wax) gets really thick in the cold and tends to not allow the casing to extract easily if too much is applied, the beeswax actually gummed things up both in the cold and warm climate if too much is applied. Even though the Alox groups did improve group size, I omitted the Alox photos as the silicone groups were smaller, and the amount of stuck casings due to the Alox in cold temperatures now made it less of a good lube to use in cold climates thus bumping down the ladder as a preferrable lube for year roound shooting.

So the silicone grease seemed to be the answer as far as the consistancy goes while on the ammo, both in cold and warm climate. But how will it fare on paper?

Seemed to have fared very well, and has a few additional advantages I didn't consider before:

1. Easy to apply - either by fingertip or a small paintbrush

2. Stays pliable in cold, doesn't liquify in warmth.

3. No distinctive odor or staining color.

4. Doesn't get cases stuck in the chamber even if a rediculous amount is applied.

5. Actually works well as a rust inhibitor. Next pictures are two nails. "U" is uncoated, "C" is coated. Top is before, bottom is after being let sit in a saltwater solution overnight, removed, then left to sit for 7 days in a somewhat humid basement.

6. Actually works pretty good as a bolt lube - I put a little on my bolt and any bolt guides, wiped off the excess, cycling is very smooth.

7. Causes less fouling in the barrel. Took alot less patches to wipe barrel fouling out of the barrel once the barrel was cleaned, silicone grease applied, then 100 rounds shot as compared to other protectants or lubes I've used.

So on to the targets. I used a Savage MKII F sproter barreled rifle as it tends to show up differences in ammos and lubes more distinctively, bipod, rear bag from the bench. Optic was on 12 X at 50yds, 14x at 100. A 1" circle was used as the point of aim. Temperature was 29 deg F, 55% humidity, wind 5-7 MPH 5:00, cloudy. 10 round groups were fired with being unlubed, lubed with Alox, and lubed with the silicone grease. The barrel was dry patched before each ammo or new lube was introduced, then 10 rounds of the different ammo or new lube was shot off paper to get the barrel somewhat conditioned to the new ammo / lube. Each round was weighed and rim thickness sorted, then shot sequentially with the greatest amount of weight and rim thickness difference to allow the greatest amount of deviation in the ammo itself and have the groups rely on the lube itself. They were shot through a chronograh, the treated ammo FPS increased on average 10- 15 FPS as compared to the untreated.

I omitted the Alox groups in the pictures for the CCI standard velocity and Fed bulk ammo (as the FTE problem mentioned previously made the Alox less than optimal in cold weather). The CCI blazer target had gotten destroyed due to a "misplaced" cup of coffee, however both the Alox and silicone had improved the CCI Blazer groups at 50 and 100 yards, with the Alox shrinking the groups by .25" @ 100, and the silicone by at least .5" @ 100 for an average 1.25" group.

CCI Standard Velocity:

Fed. bulk (a few extra shot were taken on the unlubed, as the group was quite open at first and remained open even after the additional rounds):

200 yard (from a previous session, prone, bipod, and no rear support. Will shoot 200 yd again from bench and rear support in the future when the wind conditions will facilitate better objective results):

WITHOUT ADDITIONAL LUBE (12" X 8.5" group)

WITH ADDITIONAL LUBE group shrank to 6.5" x 5.75", even with the MKII F

The silicone grease did leave a little slippery feeling on my fingertips while loading, however not any more excessive than the Wolf MT or a similiar lubed ammo would.

As I had good results with Moly and graphite in the past, the next step may be to mix a little with the grease and see what happens. I'm forcasting that it may leave a grey slippery susbstance that may stain fingers and clothing, but may produce even better results than just the grease alone. As my stock of various ammos has been depleted after this test, it will probably incorporate only the CCI Standard Velocity, Fed. bulk, and Wolf MT as a comparison.

In the mean time I'll try to locate the manufacturer of this particular silicone grease so i don't have to "borrow" it from work and post the source of supply at a later date. But I would believe that any similar high temp / low temp silicone grease should suffice.

For whatever reason I cannot edit that bullet lube post linked in the top of this post, so to give an updated rundown of lubrication I've tried:

FOR PURELY GROUP SIZE:

1. Moly or graphite lube spray

2. Silicone grease

3. Bowstring wax (Beeswax)

4. Alox bullet lube

5. Parrafin wax

6. Carnuba wax and Crayon tied

7. White lithium grease

8. Crossbow rail lube, RCBS case lube, Pam high temp cooking sray, furniture wax, pledge, miltec and other gun lubes - all not providing much difference in group size.

FOR COST, EASE OF APPLICATION, DRAWBACKS, AND GROUP SIZE:

1. Silicone grease (cost per generic Google search for silicone greases)

2. Carnuba wax - easy to apply, economical, stable in different temperatures.

3. Bowstring wax (Beeswax) - easy to apply, economical, but tends to gum up magzines, bolts, and chambers if excessive amounts are applied.

4. Alox bullet lube - easy to apply, economical, but causes stuck shells in cold temperatures if excessive amounts are applied.

5. Moly or graphite spray lube - Gave best group results, but is pricey, more intensive to apply, stains fingers and clothing.

6. White lithium grease - easy to apply, not that expensive, but leaves a tacky residue over everything.

7. Parrafin wax - economical, best applied if melted and ammo is dipped which is a bit time consuming and a little messy.

8. Crayon - easy to apply, economical, doesn't adhere well (flakes off).

I tried 3 different ammos - CCI Standard Velocity, Fed bulk pack, CCI blazer, and then used a group of Wolf MT as a comparison. For todays trial, I shot 50 and 100 yards, the 200 yard targets below were from another session.

I've done alot of lube testing using the different lubes on different ammos. Just going on group sizes alone without having a complicated recipe, Moly or graphite spray lube rated #1, Bowstring wax (beeswax) being #2, and Alox bullet lube being #3. Another 10 types of lubes / waxes were tested 22 ammo lubrication

The drawback to the moly or graphite spray is that it was almost as pricey as to just purchase match ammo and time consuming to spray on a large amount of ammo. I just found out today that the Alox bullet lube (which has the consistancy of ear wax) gets really thick in the cold and tends to not allow the casing to extract easily if too much is applied, the beeswax actually gummed things up both in the cold and warm climate if too much is applied. Even though the Alox groups did improve group size, I omitted the Alox photos as the silicone groups were smaller, and the amount of stuck casings due to the Alox in cold temperatures now made it less of a good lube to use in cold climates thus bumping down the ladder as a preferrable lube for year roound shooting.

So the silicone grease seemed to be the answer as far as the consistancy goes while on the ammo, both in cold and warm climate. But how will it fare on paper?

Seemed to have fared very well, and has a few additional advantages I didn't consider before:

1. Easy to apply - either by fingertip or a small paintbrush

2. Stays pliable in cold, doesn't liquify in warmth.

3. No distinctive odor or staining color.

4. Doesn't get cases stuck in the chamber even if a rediculous amount is applied.

5. Actually works well as a rust inhibitor. Next pictures are two nails. "U" is uncoated, "C" is coated. Top is before, bottom is after being let sit in a saltwater solution overnight, removed, then left to sit for 7 days in a somewhat humid basement.

6. Actually works pretty good as a bolt lube - I put a little on my bolt and any bolt guides, wiped off the excess, cycling is very smooth.

7. Causes less fouling in the barrel. Took alot less patches to wipe barrel fouling out of the barrel once the barrel was cleaned, silicone grease applied, then 100 rounds shot as compared to other protectants or lubes I've used.

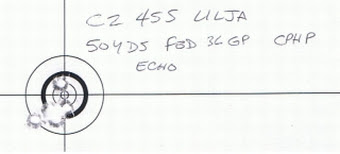

So on to the targets. I used a Savage MKII F sproter barreled rifle as it tends to show up differences in ammos and lubes more distinctively, bipod, rear bag from the bench. Optic was on 12 X at 50yds, 14x at 100. A 1" circle was used as the point of aim. Temperature was 29 deg F, 55% humidity, wind 5-7 MPH 5:00, cloudy. 10 round groups were fired with being unlubed, lubed with Alox, and lubed with the silicone grease. The barrel was dry patched before each ammo or new lube was introduced, then 10 rounds of the different ammo or new lube was shot off paper to get the barrel somewhat conditioned to the new ammo / lube. Each round was weighed and rim thickness sorted, then shot sequentially with the greatest amount of weight and rim thickness difference to allow the greatest amount of deviation in the ammo itself and have the groups rely on the lube itself. They were shot through a chronograh, the treated ammo FPS increased on average 10- 15 FPS as compared to the untreated.

I omitted the Alox groups in the pictures for the CCI standard velocity and Fed bulk ammo (as the FTE problem mentioned previously made the Alox less than optimal in cold weather). The CCI blazer target had gotten destroyed due to a "misplaced" cup of coffee, however both the Alox and silicone had improved the CCI Blazer groups at 50 and 100 yards, with the Alox shrinking the groups by .25" @ 100, and the silicone by at least .5" @ 100 for an average 1.25" group.

CCI Standard Velocity:

Fed. bulk (a few extra shot were taken on the unlubed, as the group was quite open at first and remained open even after the additional rounds):

200 yard (from a previous session, prone, bipod, and no rear support. Will shoot 200 yd again from bench and rear support in the future when the wind conditions will facilitate better objective results):

WITHOUT ADDITIONAL LUBE (12" X 8.5" group)

WITH ADDITIONAL LUBE group shrank to 6.5" x 5.75", even with the MKII F

The silicone grease did leave a little slippery feeling on my fingertips while loading, however not any more excessive than the Wolf MT or a similiar lubed ammo would.

As I had good results with Moly and graphite in the past, the next step may be to mix a little with the grease and see what happens. I'm forcasting that it may leave a grey slippery susbstance that may stain fingers and clothing, but may produce even better results than just the grease alone. As my stock of various ammos has been depleted after this test, it will probably incorporate only the CCI Standard Velocity, Fed. bulk, and Wolf MT as a comparison.

In the mean time I'll try to locate the manufacturer of this particular silicone grease so i don't have to "borrow" it from work and post the source of supply at a later date. But I would believe that any similar high temp / low temp silicone grease should suffice.

For whatever reason I cannot edit that bullet lube post linked in the top of this post, so to give an updated rundown of lubrication I've tried:

FOR PURELY GROUP SIZE:

1. Moly or graphite lube spray

2. Silicone grease

3. Bowstring wax (Beeswax)

4. Alox bullet lube

5. Parrafin wax

6. Carnuba wax and Crayon tied

7. White lithium grease

8. Crossbow rail lube, RCBS case lube, Pam high temp cooking sray, furniture wax, pledge, miltec and other gun lubes - all not providing much difference in group size.

FOR COST, EASE OF APPLICATION, DRAWBACKS, AND GROUP SIZE:

1. Silicone grease (cost per generic Google search for silicone greases)

2. Carnuba wax - easy to apply, economical, stable in different temperatures.

3. Bowstring wax (Beeswax) - easy to apply, economical, but tends to gum up magzines, bolts, and chambers if excessive amounts are applied.

4. Alox bullet lube - easy to apply, economical, but causes stuck shells in cold temperatures if excessive amounts are applied.

5. Moly or graphite spray lube - Gave best group results, but is pricey, more intensive to apply, stains fingers and clothing.

6. White lithium grease - easy to apply, not that expensive, but leaves a tacky residue over everything.

7. Parrafin wax - economical, best applied if melted and ammo is dipped which is a bit time consuming and a little messy.

8. Crayon - easy to apply, economical, doesn't adhere well (flakes off).