Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: HasgunWilltravel</div><div class="ubbcode-body">Very, very nice. Makes me wish I would have learned to use a lathe instead of a sewing machine.

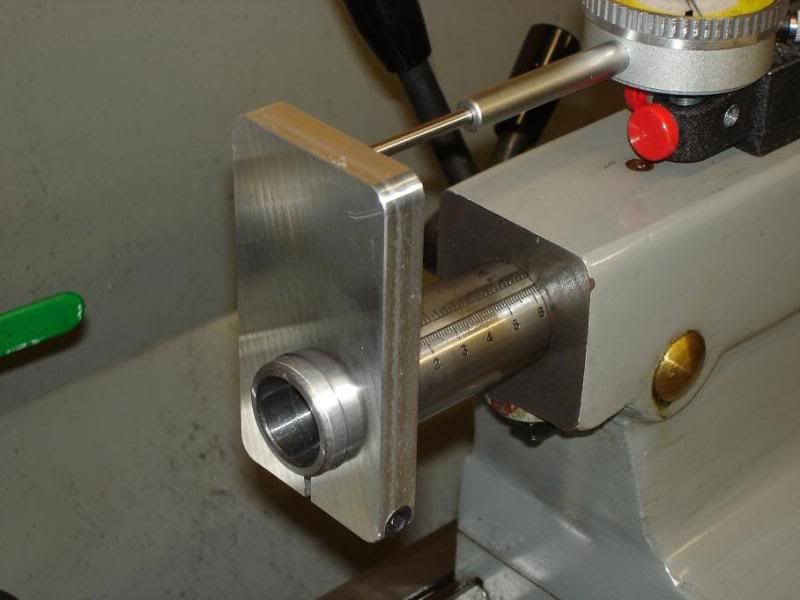

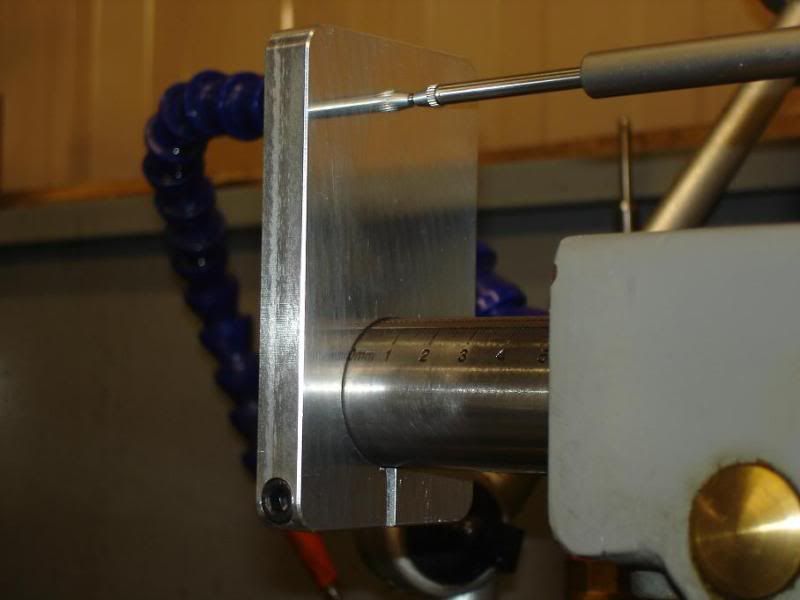

Please document that .308 your bulding, and please include pics this time of chambering the barrel

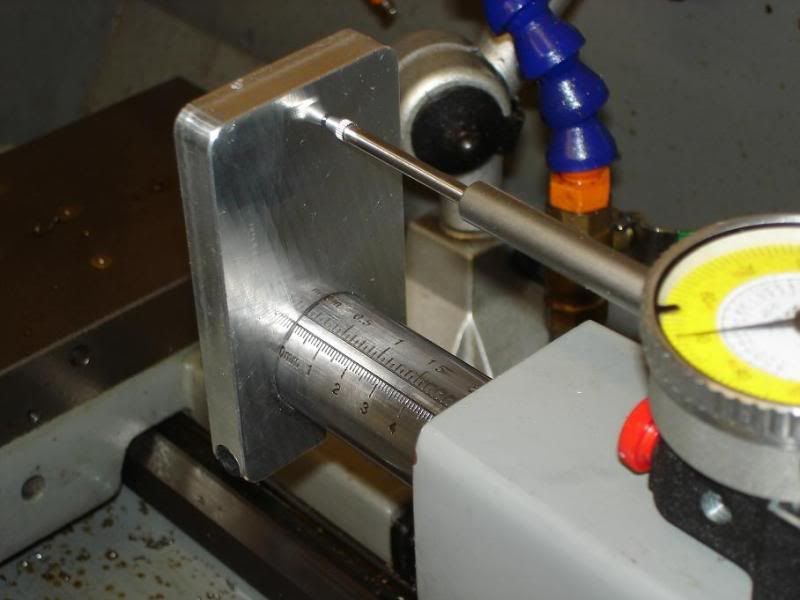

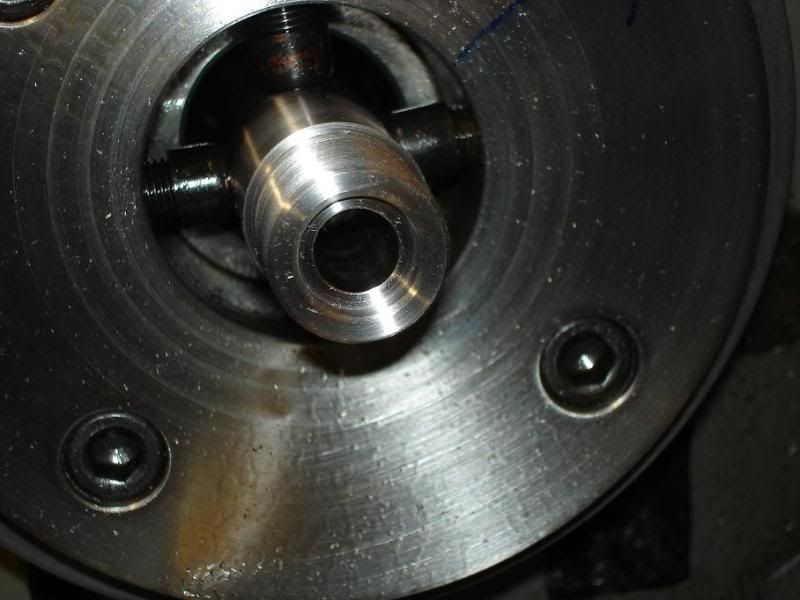

Also, please explain how you measure how deep to cut the chamber, I always figued you got it close, then finished by hand while trying no/no-go guages....this was a complete mystery to me until I read this thread, thanks for shining some light for the green horns. </div></div>

i keep wanting to get a sewing machine but i am afraid people would get the wrong idea if i had a sewing machine <span style="font-style: italic">and</span> drive a miata

. i need long action aics mag pouches but no one makes them.

</div></div>

Tell me what you want made, and I will get something together for you, if you want to swap out a little gear making work for chambering work, I am all ears too!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: wnroscoe</div><div class="ubbcode-body">

Come on girls, next you'll be swapping recipes

Nick, see what living up north will do to you.</div></div>

Roscoe, I want my Madonna C.D.'s back.

Please back on subject, I would prefer not soil a thread with so much usefull information in it with meaningless drivel.