Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: my home shop .284 win build (pic heavy)

300sniper,

This thread immediately went to the top of my list. Before the end of your rebuild, you verified and showed the results to everyone who wished for viewing and confirming.

You described conditions that “made you nervous” was quite accurate and hit home with me. I have had those feelings at different times and I am hoping after my overall machining skills improve and I performed the same cut on a barrel several more times I will have either ruined one or be able to settle down and my heart not be beating like a lizard.

Another legitimate suggestion would be to treat this thread as a living document; but not like the Republicans and Democrats treat and show disdain for the US Constitution, their living document.

Simply add more description, interpretations, why you did something and why you didn’t. There are some excellent comments by others and even why one used HSS instead of carbide reamers and justified his methodology. You will do more smithing so the opportunity will avail itself.

I do believe I have seen my fair share of machining instructional videos and if there is a consistent weakness in most are the “thought process” speak and sometime the simplest of technique is withheld, not spoken or seen on video (e.g. a feed rate, a dial/test indicator setup, and realistic alignment/run-out times). My intent in no way is to diss the sharing and helpful time and expense many very highly qualified smiths took to produce instructional DVDs.

Go back and delete some of the superfluous comments like mine and Viola! SnipersHide, compliments of 300sniper, et. al, has an online instructional that augments Hinnants’s book, and countless DVDs and magazine articles.

Being a FNG, what is still really surprising to me is the love and respect most of the experienced gunsmiths have for their vo/avocation. There is an extremely limited field of interest out there and obviously more than a handful have covied up on this forum. I have found when successful and qualified smith has time; they love to talk about what they do and how they do it, especially when they have a hungry audience (snipershide).

One does not have to be interested in purchasing a Grizzly or South Bend lathe, build a shop or what have you to start their own gunsmith shop so they can improve their two gee-whiz rifles and one hunting stick. If, at the very least, it will confirm to some bloke reading your post (along with the others that contributed) what the meaning of simple terms like “lapping the lugs” or “blueprinting an action” means.

To end my missive (I heard that!), years ago, when I had trouble remembering which end you put the gasoline in the rifle, I had a Rem 700 completely “accurized.” Blueprint or true the action, bolt face, lug abutments, have the lugs lapped; reinstall the crown, blah, blah, blah. I got it back several months later and shot it. The smith was honest and told me he just couldn’t get any real discernable improvement out of it but he thought it shot just a tiny bit better than before (factory ammo).

Several months ago I was digging in my gun safe and yanked this beauty out to see, look and learn. Short of the story is there wasn’t a tool mark one on the bolt, bolt face, or action. Apparently I could parrot the words but I didn’t have a clue what they meant. Therefore I got a bucketful of my money’s worth in real-life lessons.

Cheers!

300sniper,

This thread immediately went to the top of my list. Before the end of your rebuild, you verified and showed the results to everyone who wished for viewing and confirming.

You described conditions that “made you nervous” was quite accurate and hit home with me. I have had those feelings at different times and I am hoping after my overall machining skills improve and I performed the same cut on a barrel several more times I will have either ruined one or be able to settle down and my heart not be beating like a lizard.

Another legitimate suggestion would be to treat this thread as a living document; but not like the Republicans and Democrats treat and show disdain for the US Constitution, their living document.

Simply add more description, interpretations, why you did something and why you didn’t. There are some excellent comments by others and even why one used HSS instead of carbide reamers and justified his methodology. You will do more smithing so the opportunity will avail itself.

I do believe I have seen my fair share of machining instructional videos and if there is a consistent weakness in most are the “thought process” speak and sometime the simplest of technique is withheld, not spoken or seen on video (e.g. a feed rate, a dial/test indicator setup, and realistic alignment/run-out times). My intent in no way is to diss the sharing and helpful time and expense many very highly qualified smiths took to produce instructional DVDs.

Go back and delete some of the superfluous comments like mine and Viola! SnipersHide, compliments of 300sniper, et. al, has an online instructional that augments Hinnants’s book, and countless DVDs and magazine articles.

Being a FNG, what is still really surprising to me is the love and respect most of the experienced gunsmiths have for their vo/avocation. There is an extremely limited field of interest out there and obviously more than a handful have covied up on this forum. I have found when successful and qualified smith has time; they love to talk about what they do and how they do it, especially when they have a hungry audience (snipershide).

One does not have to be interested in purchasing a Grizzly or South Bend lathe, build a shop or what have you to start their own gunsmith shop so they can improve their two gee-whiz rifles and one hunting stick. If, at the very least, it will confirm to some bloke reading your post (along with the others that contributed) what the meaning of simple terms like “lapping the lugs” or “blueprinting an action” means.

To end my missive (I heard that!), years ago, when I had trouble remembering which end you put the gasoline in the rifle, I had a Rem 700 completely “accurized.” Blueprint or true the action, bolt face, lug abutments, have the lugs lapped; reinstall the crown, blah, blah, blah. I got it back several months later and shot it. The smith was honest and told me he just couldn’t get any real discernable improvement out of it but he thought it shot just a tiny bit better than before (factory ammo).

Several months ago I was digging in my gun safe and yanked this beauty out to see, look and learn. Short of the story is there wasn’t a tool mark one on the bolt, bolt face, or action. Apparently I could parrot the words but I didn’t have a clue what they meant. Therefore I got a bucketful of my money’s worth in real-life lessons.

Cheers!

Re: my home shop .284 win build (pic heavy)

300sniper,

I so much want you to get a gunshop up and running!

Regards

300sniper,

I so much want you to get a gunshop up and running!

Regards

Re: my home shop .284 win build (pic heavy)

Can you provide a little more information on the brass bushings you used to hold the indicator rod for the actions, dimensions? Or can anyone else give me a few pointers on what to use as an indicator rod and bushing for trueing an action?

Can you provide a little more information on the brass bushings you used to hold the indicator rod for the actions, dimensions? Or can anyone else give me a few pointers on what to use as an indicator rod and bushing for trueing an action?

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: osuarchitect</div><div class="ubbcode-body">Can you provide a little more information on the brass bushings you used to hold the indicator rod for the actions, dimensions? Or can anyone else give me a few pointers on what to use as an indicator rod and bushing for trueing an action? </div></div>

the bushings were made for that action and may work for others. i don't remember the dimensions off the top of my head but i remember they were not the same size even in that same receiver. if you are going to do more than one of them, it may be worth looking into getting the bushings from pacific tool an gauge. they are way to expensive for doing one receiver though.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: osuarchitect</div><div class="ubbcode-body">Can you provide a little more information on the brass bushings you used to hold the indicator rod for the actions, dimensions? Or can anyone else give me a few pointers on what to use as an indicator rod and bushing for trueing an action? </div></div>

the bushings were made for that action and may work for others. i don't remember the dimensions off the top of my head but i remember they were not the same size even in that same receiver. if you are going to do more than one of them, it may be worth looking into getting the bushings from pacific tool an gauge. they are way to expensive for doing one receiver though.

Re: my home shop .284 win build (pic heavy)

Dang you have some talent. That equipment is in your garage?

Dang you have some talent. That equipment is in your garage?

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: problemchild</div><div class="ubbcode-body">Dang you have some talent. That equipment is in your garage? </div></div>

it is my equipment but it is actually all in a friend's garage/shop.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: problemchild</div><div class="ubbcode-body">Dang you have some talent. That equipment is in your garage? </div></div>

it is my equipment but it is actually all in a friend's garage/shop.

Re: my home shop .284 win build (pic heavy)

amazing work. especially on that break. i wish i could do this stuff.

i apologize if this has already been covered earlier in the thread, but would you ever consider making a few of those breaks and selling em on here? i bet alot of people would be interested

amazing work. especially on that break. i wish i could do this stuff.

i apologize if this has already been covered earlier in the thread, but would you ever consider making a few of those breaks and selling em on here? i bet alot of people would be interested

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Chickeneye</div><div class="ubbcode-body">

i apologize if this has already been covered earlier in the thread, but would you ever consider making a few of those breaks and selling em on here? i bet alot of people would be interested </div></div>

not that particular brake but i do have another one designed that will mount with the same dimensions as a badger fte. i am in the process of writing the program for it now. one of these days i'll get around to finishing it. while i have the machine set up, i am going to make at least 6 of them but 3 are already spoken for. i may sell the remaining ones but i won't know until then.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Chickeneye</div><div class="ubbcode-body">

i apologize if this has already been covered earlier in the thread, but would you ever consider making a few of those breaks and selling em on here? i bet alot of people would be interested </div></div>

not that particular brake but i do have another one designed that will mount with the same dimensions as a badger fte. i am in the process of writing the program for it now. one of these days i'll get around to finishing it. while i have the machine set up, i am going to make at least 6 of them but 3 are already spoken for. i may sell the remaining ones but i won't know until then.

Re: my home shop .284 win build (pic heavy)

I just read all 9 pages of that thread over on "snipercentral".

That guy has the patience of a saint.

I cannot believe how gentlemanly he acted throughout the whole ordeal.

I take my hat off you LA Precision you went above and beyond to help the guy.

This is a great site and 300sniper, this has been one of the most informative post I have ever read.

Thank you

I just read all 9 pages of that thread over on "snipercentral".

That guy has the patience of a saint.

I cannot believe how gentlemanly he acted throughout the whole ordeal.

I take my hat off you LA Precision you went above and beyond to help the guy.

This is a great site and 300sniper, this has been one of the most informative post I have ever read.

Thank you

Re: my home shop .284 win build (pic heavy)

I can't wait to see the end results. This one of the, if not the best post I've seen. Please, keep it coming.

I can't wait to see the end results. This one of the, if not the best post I've seen. Please, keep it coming.

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: STR</div><div class="ubbcode-body">I can't wait to see the end results. This one of the, if not the best post I've seen. Please, keep it coming. </div></div>

lol. i'm about to order my second barrel so i have it ready when this one is done. at about 2k rounds, this one is still shooting damn good. from the other guys around here shooting the same load in their 284's, it sounds like about 3k rounds is where they let go.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: STR</div><div class="ubbcode-body">I can't wait to see the end results. This one of the, if not the best post I've seen. Please, keep it coming. </div></div>

lol. i'm about to order my second barrel so i have it ready when this one is done. at about 2k rounds, this one is still shooting damn good. from the other guys around here shooting the same load in their 284's, it sounds like about 3k rounds is where they let go.

Re: my home shop .284 win build (pic heavy)

Hi 300sniper,

what is the barrel round count now on your barrel?

Is it still shooting great?

Hi 300sniper,

what is the barrel round count now on your barrel?

Is it still shooting great?

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: jp67</div><div class="ubbcode-body">Hi 300sniper,

what is the barrel round count now on your barrel?

Is it still shooting great? </div></div>

i am right around 2k rounds and it is shooting as good now as ever. the 7mm 175 grain smks dried up around october last year and sierra still haven't made more. i have not even been shooting this rifle this year because of the bullet supply.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: jp67</div><div class="ubbcode-body">Hi 300sniper,

what is the barrel round count now on your barrel?

Is it still shooting great? </div></div>

i am right around 2k rounds and it is shooting as good now as ever. the 7mm 175 grain smks dried up around october last year and sierra still haven't made more. i have not even been shooting this rifle this year because of the bullet supply.

Re: my home shop .284 win build (pic heavy)

What AICS mag are you using?(.338 or .300)

Did you have to modify it for the .284?

I have had this .284 winch project in mind for some time.

I have purchased the AICS stock and the Tac 300 action but just can't make up my mind regarding this caliber.

What do you think i should do? Go bigger?

Thanks

What AICS mag are you using?(.338 or .300)

Did you have to modify it for the .284?

I have had this .284 winch project in mind for some time.

I have purchased the AICS stock and the Tac 300 action but just can't make up my mind regarding this caliber.

What do you think i should do? Go bigger?

Thanks

Re: my home shop .284 win build (pic heavy)

the 284 feeds fine from the 300 win aics magazines. you may have to tweak the feed lips slightly though. some i didn't have to do anything to and others i had to bend the feed lips.

the 284 feeds fine from the 300 win aics magazines. you may have to tweak the feed lips slightly though. some i didn't have to do anything to and others i had to bend the feed lips.

Re: my home shop .284 win build (pic heavy)

Thanks

How does the .284 winch compare with your .300 Winch mag?

Same or better?

Thanks

How does the .284 winch compare with your .300 Winch mag?

Same or better?

Re: my home shop .284 win build (pic heavy)

300 win mag still has the ballistic edge but at a cost. the 300 win mag is harder to shoot good due to the recoil. the 210 vld bullets are much more expensive. it burns 20+ grains more powder each time the trigger is pulled. the barrel life is shorter.

i will always have a 300 win mag. i am planning on rebarreling my 300 this year and dedicate it to beyond 1k yard use.

300 win mag still has the ballistic edge but at a cost. the 300 win mag is harder to shoot good due to the recoil. the 210 vld bullets are much more expensive. it burns 20+ grains more powder each time the trigger is pulled. the barrel life is shorter.

i will always have a 300 win mag. i am planning on rebarreling my 300 this year and dedicate it to beyond 1k yard use.

Re: my home shop .284 win build (pic heavy)

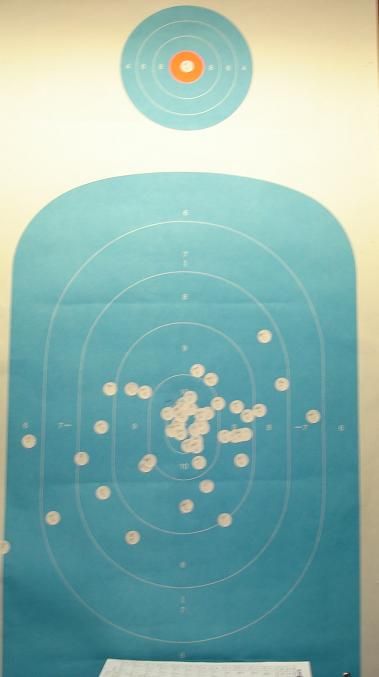

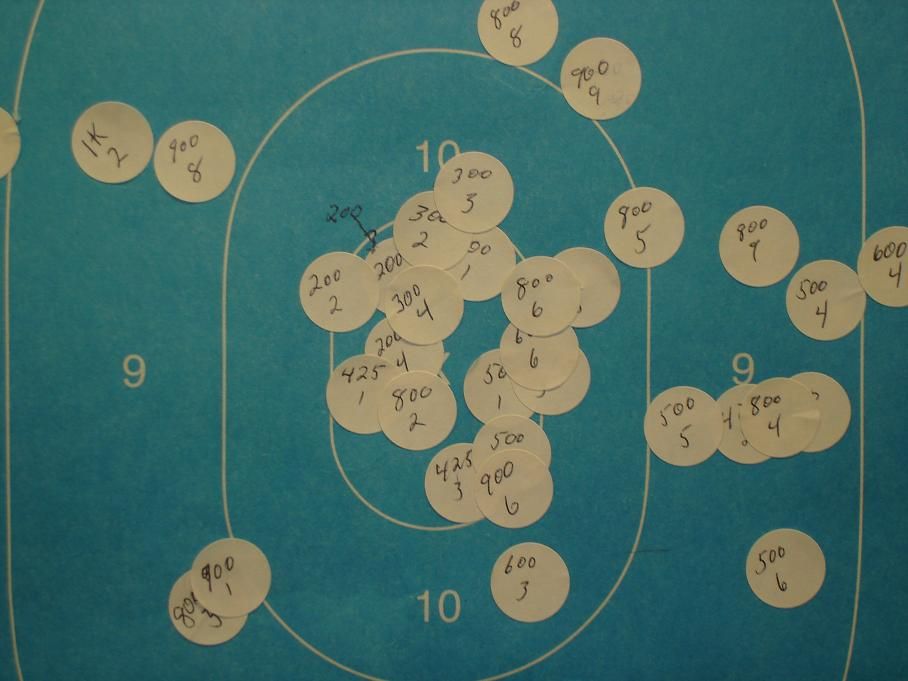

after shooting my 18" 308 in our long range match for the first 5 months this year and getting my butt kicked, i finally got some more 7mm 175 smks. first match back with the 284 and i got this:

i'd say the rifle turned out just fine.

after shooting my 18" 308 in our long range match for the first 5 months this year and getting my butt kicked, i finally got some more 7mm 175 smks. first match back with the 284 and i got this:

i'd say the rifle turned out just fine.

Re: my home shop .284 win build (pic heavy)

They gave it to you empty? That's just wrong.

Damn fine rifle though.

They gave it to you empty? That's just wrong.

Damn fine rifle though.

Re: my home shop .284 win build (pic heavy)

Awesome thread! Glad it got bumped.

Nice work and good shooting!

Awesome thread! Glad it got bumped.

Nice work and good shooting!

Re: my home shop .284 win build (pic heavy)

I love your posts 300sniper. They inspire me to get back into machining!

I love your posts 300sniper. They inspire me to get back into machining!

Re: my home shop .284 win build (pic heavy)

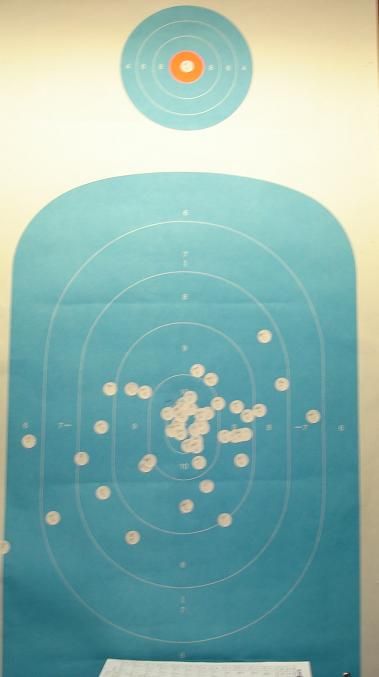

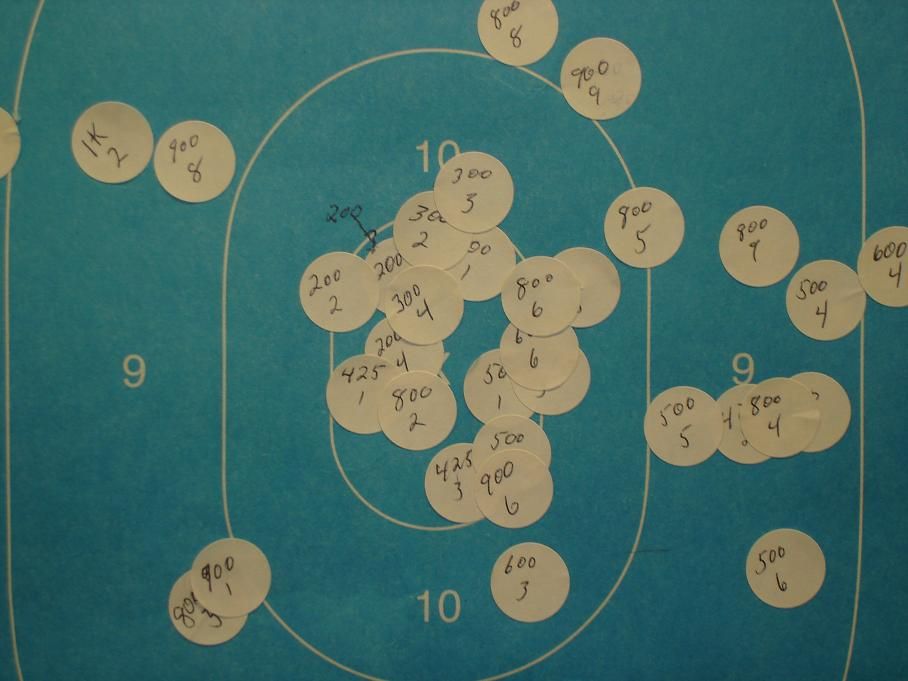

second month in a row

this rifle is shooting insanely well. my first stage at the 500 yard line put three of three rounds into a 3/4" group in the x-ring.

second month in a row

this rifle is shooting insanely well. my first stage at the 500 yard line put three of three rounds into a 3/4" group in the x-ring.

Re: my home shop .284 win build (pic heavy)

300sniper,

I think I justed watched the highlights of this shoot on CS tactical podcast, awesome rifles, and awesome shooting there. Prizes looking GREAT as well, especially that rifle GAP rifle, and the KMW stock!

300sniper,

I think I justed watched the highlights of this shoot on CS tactical podcast, awesome rifles, and awesome shooting there. Prizes looking GREAT as well, especially that rifle GAP rifle, and the KMW stock!

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 308JEFF</div><div class="ubbcode-body">300sniper,

I think I justed watched the highlights of this shoot on CS tactical podcast, awesome rifles, and awesome shooting there. Prizes looking GREAT as well, especially that rifle GAP rifle, and the KMW stock! </div></div>

that was the nor-cal tbrc, the club's anual big match. I didn't shoot that match but worked in the pits instead. It was the last two monthly matches I won. I am hoping to shoot tbrc next year.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 308JEFF</div><div class="ubbcode-body">300sniper,

I think I justed watched the highlights of this shoot on CS tactical podcast, awesome rifles, and awesome shooting there. Prizes looking GREAT as well, especially that rifle GAP rifle, and the KMW stock! </div></div>

that was the nor-cal tbrc, the club's anual big match. I didn't shoot that match but worked in the pits instead. It was the last two monthly matches I won. I am hoping to shoot tbrc next year.

Re: my home shop .284 win build (pic heavy)

ohh IC, great variety of rifle out there though. which hawaii had shoots like that. Might have to cross the pond one of these day and give it a try, it looks very addicting and fun!

ohh IC, great variety of rifle out there though. which hawaii had shoots like that. Might have to cross the pond one of these day and give it a try, it looks very addicting and fun!

Re: my home shop .284 win build (pic heavy)

this rifle is still shooting insanely well (and i'm not doing too shabby myself, if i may brag

). out of the last four matches i shot with this rifle (the only matches i have used it in this year), i took first in three of them and second in the other.

). out of the last four matches i shot with this rifle (the only matches i have used it in this year), i took first in three of them and second in the other.

i think i am at about 2200 rounds out of this barrel now. right now it is shooting as good as it ever has but i ordered another broughton barrel for it today so i have it when i need it. instead of the 7.1 contour of this build, i am going with their heavy palma 12.4 contour. i finished this one at 27" and plan on 28" for the new one. i am guessing it will be about half a pound lighter with the new configuration.

this rifle is still shooting insanely well (and i'm not doing too shabby myself, if i may brag

i think i am at about 2200 rounds out of this barrel now. right now it is shooting as good as it ever has but i ordered another broughton barrel for it today so i have it when i need it. instead of the 7.1 contour of this build, i am going with their heavy palma 12.4 contour. i finished this one at 27" and plan on 28" for the new one. i am guessing it will be about half a pound lighter with the new configuration.

Re: my home shop .284 win build (pic heavy)

I can personally attest to watching this rifle hammer the target at 500, 600, 800, 900, and 1K! Shooting a few down the line from 300sniper has me questioning where I came up with any of my wind calls and wondering how the hell he can place all of his in the center with the winds shifting at that range!!!!

Definitely some nice shooting (and nice stick).

I can personally attest to watching this rifle hammer the target at 500, 600, 800, 900, and 1K! Shooting a few down the line from 300sniper has me questioning where I came up with any of my wind calls and wondering how the hell he can place all of his in the center with the winds shifting at that range!!!!

Definitely some nice shooting (and nice stick).

Re: my home shop .284 win build

<span style="color: #3333FF">Best article I have EVER seen on how to true an action!

If only someone were doing this level of work on Mauser actions...</span>

<span style="color: #3333FF">Best article I have EVER seen on how to true an action!

If only someone were doing this level of work on Mauser actions...</span>

Re: my home shop .284 win build

2010 was an awesome year for this rifle (and myself [pats self on shoulder

]). of the 8 matches i shot with it, i had 3 wins and 2 second places. it was good enough to get the top shooter of the year for our local long range matches.

]). of the 8 matches i shot with it, i had 3 wins and 2 second places. it was good enough to get the top shooter of the year for our local long range matches.

even with 2600 round down the barrel, it was still shooting unbelievably well today. i don't expect the barrel will hold up much longer though. i have a new blank on hand when i do need to swap it out in the next month or two.

2010 was an awesome year for this rifle (and myself [pats self on shoulder

even with 2600 round down the barrel, it was still shooting unbelievably well today. i don't expect the barrel will hold up much longer though. i have a new blank on hand when i do need to swap it out in the next month or two.

Re: my home shop .284 win build (pic heavy)

It great when people take the time to illistrate some of the work they are performing wheather or not its commercial or personal. It answers so many question as a pick tells a thousand words. Whats even more impressive, not only for the OP but other posters as well the lack of secrecy. Its awsome.

Thanks for making threads like this.

It great when people take the time to illistrate some of the work they are performing wheather or not its commercial or personal. It answers so many question as a pick tells a thousand words. Whats even more impressive, not only for the OP but other posters as well the lack of secrecy. Its awsome.

Thanks for making threads like this.

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Graham</div><div class="ubbcode-body">I'm working-up loads for my .284 as a match gun for next year.

What's your max load with 180's and 4831SC?

Can you do 57+ grains? </div></div>

i haven't even messed with the 180's. i tried a pet load that some other local guys are running and it worked so good i stayed with it. 54.5 grains of 4831sc, 175 smk, winchester brass, and a br2 primer. i have a 30"+ barrel blank sitting on the shelf now that i will install in the next month or two. with the longer barrel i may mess with loads a bit.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Graham</div><div class="ubbcode-body">I'm working-up loads for my .284 as a match gun for next year.

What's your max load with 180's and 4831SC?

Can you do 57+ grains? </div></div>

i haven't even messed with the 180's. i tried a pet load that some other local guys are running and it worked so good i stayed with it. 54.5 grains of 4831sc, 175 smk, winchester brass, and a br2 primer. i have a 30"+ barrel blank sitting on the shelf now that i will install in the next month or two. with the longer barrel i may mess with loads a bit.

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: J.R. Sherman</div><div class="ubbcode-body">Well after reading the .308 thread, I had to read this one too. I'd say you're long past being a learner machinist man! Congrats on both rifles and keep up the good work! </div></div>

thanks.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: jester1</div><div class="ubbcode-body">It great when people take the time to illistrate some of the work they are performing wheather or not its commercial or personal. It answers so many question as a pick tells a thousand words. Whats even more impressive, not only for the OP but other posters as well the lack of secrecy. Its awsome.

Thanks for making threads like this. </div></div>

i enjoy doing the work and also enjoy documenting it. when i started, information was out there but you had to look in so many different places to find it all. i hope my threads inspire people to take on projects of their own. i also hope people think about why they are doing what they are and not just doing it that way because some guy on the internet says that's how it should be done.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: J.R. Sherman</div><div class="ubbcode-body">Well after reading the .308 thread, I had to read this one too. I'd say you're long past being a learner machinist man! Congrats on both rifles and keep up the good work! </div></div>

thanks.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: jester1</div><div class="ubbcode-body">It great when people take the time to illistrate some of the work they are performing wheather or not its commercial or personal. It answers so many question as a pick tells a thousand words. Whats even more impressive, not only for the OP but other posters as well the lack of secrecy. Its awsome.

Thanks for making threads like this. </div></div>

i enjoy doing the work and also enjoy documenting it. when i started, information was out there but you had to look in so many different places to find it all. i hope my threads inspire people to take on projects of their own. i also hope people think about why they are doing what they are and not just doing it that way because some guy on the internet says that's how it should be done.

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Graham</div><div class="ubbcode-body">I'm working-up loads for my .284 as a match gun for next year.

What's your max load with 180's and 4831SC?

Can you do 57+ grains? </div></div>

i haven't even messed with the 180's. i tried a pet load that some other local guys are running and it worked so good i stayed with it. 54.5 grains of 4831sc, 175 smk, winchester brass, and a br2 primer. i have a 30"+ barrel blank sitting on the shelf now that i will install in the next month or two. with the longer barrel i may mess with loads a bit. </div></div>

What is your seating depth on your load right now?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Graham</div><div class="ubbcode-body">I'm working-up loads for my .284 as a match gun for next year.

What's your max load with 180's and 4831SC?

Can you do 57+ grains? </div></div>

i haven't even messed with the 180's. i tried a pet load that some other local guys are running and it worked so good i stayed with it. 54.5 grains of 4831sc, 175 smk, winchester brass, and a br2 primer. i have a 30"+ barrel blank sitting on the shelf now that i will install in the next month or two. with the longer barrel i may mess with loads a bit. </div></div>

What is your seating depth on your load right now?

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: USMC Grunt</div><div class="ubbcode-body">Does anyone have the link to the 308 thread?</div></div>

Look in the post just above yours, 300Sniper has it linked in his signature "Compact 308 build" and it's well worth the read as well.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: USMC Grunt</div><div class="ubbcode-body">Does anyone have the link to the 308 thread?</div></div>

Look in the post just above yours, 300Sniper has it linked in his signature "Compact 308 build" and it's well worth the read as well.

Re: my home shop .284 win build (pic heavy)

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Tac284</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Graham</div><div class="ubbcode-body">I'm working-up loads for my .284 as a match gun for next year.

What's your max load with 180's and 4831SC?

Can you do 57+ grains? </div></div>

i haven't even messed with the 180's. i tried a pet load that some other local guys are running and it worked so good i stayed with it. 54.5 grains of 4831sc, 175 smk, winchester brass, and a br2 primer. i have a 30"+ barrel blank sitting on the shelf now that i will install in the next month or two. with the longer barrel i may mess with loads a bit. </div></div>

What is your seating depth on your load right now?

</div></div>

3.1" oal.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Tac284</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Graham</div><div class="ubbcode-body">I'm working-up loads for my .284 as a match gun for next year.

What's your max load with 180's and 4831SC?

Can you do 57+ grains? </div></div>

i haven't even messed with the 180's. i tried a pet load that some other local guys are running and it worked so good i stayed with it. 54.5 grains of 4831sc, 175 smk, winchester brass, and a br2 primer. i have a 30"+ barrel blank sitting on the shelf now that i will install in the next month or two. with the longer barrel i may mess with loads a bit. </div></div>

What is your seating depth on your load right now?

</div></div>

3.1" oal.

Similar threads

- Replies

- 9

- Views

- 609

- Replies

- 59

- Views

- 4K