I get what you say but I’ve talk to two friends that own RimX that have more round count than me and dry fire and they don’t have any marks. Got the pics of their breech. Something doesn’t add up.Mine has the same marks. All the RimX's I have seen have the same marks. My TL3's have the same as well. I think it's just the floating bolt head. The clearance between the bolt nose and breech face is miniscule on a RimX and the bolt head floats so...it is what it is

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pics of your bolt face?I get what you say but I’ve talk to two friends that own RimX that have more round count than me and dry fire and they don’t have any marks. Got the pics of their breech. Something doesn’t add up.

I'm with you. Mine was supposed to ship 1-14. Still waiting but I get it shit happens. But last I heard it was out for nitride.

I got a shipping notification yesterday! Did you?

Mine is supposed to ship on the 26th. I called them to see if they are on track. They told me it will be close. Man, I hope it's not too far off. Got an X match in a monthI got a shipping notification yesterday! Did you?

Yes I did. I'll have it together Friday night when I get a few minutes.I got a shipping notification yesterday! Did you?

More preference than anything else.@padom what length is your barrel going to be? Is there a length for accuracy or is it all personal preference?

I like shorter for a scoped gun but longer for a gun shooting iron/match sights.

A 22rf if I recall correctly burns all of it's powder by 16". So my barrels are between 18" and 22" long. Depending on what gun it is on the little extra length for balancing the rifle.

My rebuilt 52D has a 28" long barrel and set up for iron sights.

The faster you can get the bullet out of the barrel your overall shooting accuracy can go up as well. So unless I need the barrel length....I like the 18".

I could be wrong but it looks like blow back because of the extracter but i would not worryAnyone have an idea where and what are those

Indentation on the breech face?

Benchmark barrel prefit. Barrel is brand new , I’ve shot the first 170 rounds through it and that’s what I’ve found once I inspected it after the range session. It’s catching under the nail.

No FTF or extraction issues. Feed fine. Torqued at 70 ft-lbs

View attachment 7564264

You have this problem because they are made to shoot 22lr and 17 hmr. from the same action.Mine has the same marks. All the RimX's I have seen have the same marks. My TL3's have the same as well. I think it's just the floating bolt head. The clearance between the bolt nose and breech face is miniscule on a RimX and the bolt head floats so...it is what it is

Please explain??? I'm curiousYou have this problem because they are made to shoot 22lr and 17 hmr. from the same action.

Your tolarance stack is about +.0003 like mine it did the same thing on a proof barrel. I broke everything down and measured everything to tenths . It was +.0003 at tenon which made the bolt face lightly kiss the breech face. This is not a problem. I never saw it effect accuracy ,I'll proably be extending my tenon tolarance and shaving my bolt face to reduce my head space to .044 its .0455 now.Please explain??? I'm curious

+ 3 ten thousands!!!! Show me how you measured that. ThanksYour tolarance stack is about +.0003 like mine it did the same thing on a proof barrel. I broke everything down and measured everything to tenths . It was +.0003 at tenon which made the bolt face lightly kiss the breech face. This is not a problem. I never saw it effect accuracy ,I'll proably be extending my tenon tolarance and shaving my bolt face to reduce my head space to .044 its .0455 now.

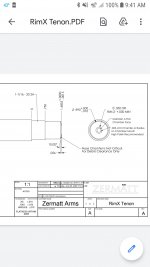

Being a 40 years plus machinest with 36 years in precision aircraft tool and die work it's not a difficult task . I clamp the barrel in my lab grade precision v blocks on my surface plate. In a vertical position its clamped to a 90deg. plate and indicated vertical in both axis to 0 the breech face is zero on the surface plate I ring then stack lab grade gauge blocks togather till I hit a go no go point. This case on mine the 1.6855 +.0000/-.0015 checked 1.6858 see attachment+ 3 ten thousands!!!! Show me how you measured that. Thanks

Attachments

Being a 40 years plus machinest with 36 years in precision aircraft tool and die work it's not a difficult task . I clamp the barrel in my lab grade precision v blocks on my surface plate. In a vertical position its clamped to a 90deg. plate and indicated vertical in both axis to 0 the breech face is zero on the surface plate I ring then stack lab grade gauge blocks togather till I hit a go no go point. This case on mine the 1.6855 +.0000/-.0015 checked 1.6858 see attachment

I also have access to state of the art optical comparators and Zeiss cmms if I have to really know ! A lot of problems in factory run components where mean tolerances are required they dont allow for push off passes the Tl2 I run will easily leave .001 sometimes if the iscar 55deg insert I use is not brand new.just wanted to make sure you weren't using a pair of Chinese digital calipers

No head space is predetermind by recess in bolt face and tenon length you'll never see better than .0455 without mods.exactly...

I’m having a failure to feed issue and was wondering if any has experienced this with the Rim-X. The round is picked up from the mag and inserted in the chamber but the. Lot will not cam over, it’s almost like it does not get under the extractor when going forward. I pull the bolt back and have to get the round out with a knife and most of the time it works just fine the second time. Has happened about 7 times the last couple mags. This set up only has about 200 rounds but just recently experienced this the last 40-50 rounds.

Your magazine height is out of location to low bullet is late rising. There is an adjustment on back of magazine, ie silver tab with torex screw mark location loosen screw move tab down. I used calipers to set mine if you go to low it will create a contact problem with underside of bolt showing 2 parallel grooves in front of drive band on bullet. The screw was proably loose and let clip slide down.I’m having a failure to feed issue and was wondering if any has experienced this with the Rim-X. The round is picked up from the mag and inserted in the chamber but the. Lot will not cam over, it’s almost like it does not get under the extractor when going forward. I pull the bolt back and have to get the round out with a knife and most of the time it works just fine the second time. Has happened about 7 times the last couple mags. This set up only has about 200 rounds but just recently experienced this the last 40-50 rounds.

Ah thanks. Come to think of it I had set it initially when installed in an MPA chassis and had no issues, just recently moved it over to a t4a. I’m sure your probably correct. Thank you I’ll go check there.

Why are you here?.

You love the rimX action It is a problem . Feeding issues is the biggest . But im sure you can tell us how to solve it

Your magazine height is out of location to low bullet is late rising. There is an adjustment on back of magazine, ie silver tab with torex screw mark location loosen screw move tab down. I used calipers to set mine if you go to low it will create a contact problem with underside of bolt showing 2 parallel grooves in front of drive band on bullet. The screw was proably loose and let clip slide down.

After playing around with it for a while it just appears I cannot slow feed the action, if I slow it down the case pops out in front of the extractor, if I run it hard it works just fine without issues.

I think he just wants to support us in our bad decisions of purchasing one of the top of the line receivers out there.Why are you here?

On mine I've installed the keystone GM barrel. I'm 58 and shoot my first NRL22 style match ever yesterday, the RimX runs flawless without any hiccups at all !

The shooter not so much, but that is a different story.

Do me a favor the stock the action came out of , take a d cell battery lay over the front action hole in stock. A d cell is 1.300 in dia. now where you bottom metal sits use your calipers and measure through the front action hole ,from the face to the battery. Write this dim. down repeat process on the current stock your action is in I promise you the stock your currently using is different, ie most likely a larger measurement here. You also need to check the tension screw on the extractor plate if it is loose it will allow for the shell to sneak in front of it due to reduced rim clearance behind it. Now with a shell in mag looking into the port so you can see the bolt face coming into contact with the shell rim slowly slowly bring bolt forward the rim should feed up and behind the extractor plate you should be 20 to 25% in before the shell reaches the clear out on mag. This is where the spring tension in mag seats the shell in the complete bolt recess and cartridge is held by opposing extractor. If it is still jumping out in front of extractor plate lower the the locator clip on back of mag .020 and repeat it will stop.After playing around with it for a while it just appears I cannot slow feed the action, if I slow it down the case pops out in front of the extractor, if I run it hard it works just fine without issues.

How does the GM shoot from John length?I think he just wants to support us in our bad decisions of purchasing one of the top of the line receivers out there.

On mine I've installed the keystone GM barrel. I'm 58 and shoot my first NRL22 style match ever yesterday, the RimX runs flawless without any hiccups at all !

The shooter not so much, but that is a different story.

It's 20 " (for some more weight) SS 1:16 M24 contour. I don't measure groups but posted pic's a while back. It shoots smaller groups at 50 Y then my B14r. It's padom's chamber, look it up in the beginning of this thread. My results are matching the ones from padom.

How does the GM shoot from John length?

Here is how my GM with my chamber shot in my original RimX review

50yd

100yd

I have a new GM RimX barrel KA sent me with a slightly modified version of my chamber they wanted me to test. Havent screwed it on yet with the weather/snow we had the last month but maybe Wednesday.. Supposed to by 55 and Sunny...

I have a new GM RimX barrel KA sent me with a slightly modified version of my chamber they wanted me to test. Havent screwed it on yet with the weather/snow we had the last month but maybe Wednesday.. Supposed to by 55 and Sunny...

I'd be interested to see how it compares. I have one on order with John. Fingers crossed some sunshine comes your way. It's warmed up here in SLC this week.

Do me a favor the stock the action came out of , take a d cell battery lay over the front action hole in stock. A d cell is 1.300 in dia. now where you bottom metal sits use your calipers and measure through the front action hole ,from the face to the battery. Write this dim. down repeat process on the current stock your action is in I promise you the stock your currently using is different, ie most likely a larger measurement here. You also need to check the tension screw on the extractor plate if it is loose it will allow for the shell to sneak in front of it due to reduced rim clearance behind it. Now with a shell in mag looking into the port so you can see the bolt face coming into contact with the shell rim slowly slowly bring bolt forward the rim should feed up and behind the extractor plate you should be 20 to 25% in before the shell reaches the clear out on mag. This is where the spring tension in mag seats the shell in the complete bolt recess and cartridge is held by opposing extractor. If it is still jumping out in front of extractor plate lower the the locator clip on back of mag .020 and repeat it will stop.

Thank you sir, I will try this. I cannot check it against the MPA matrix as I traded it off already. But I will definitely check the tension screw. Like you said it has to be something with the new stock as I didn’t have a single hiccup before.

How likely is it that a RimX will fit in a Manners stock bedded for a TL3? I have a RimX on order and was thinking of throwing it in a spare T2A I have sitting if its doable.

I would say 100%How likely is it that a RimX will fit in a Manners stock bedded for a TL3? I have a RimX on order and was thinking of throwing it in a spare T2A I have sitting if its doable.

The bolt sweeps on the TL3 and RimX are different. You will have to open up the bolt notch on the stock to allow the RimX to close properly. Then you should be good to go.

I

I have mine in a Manners for a Defiance and did have to open up the bolt notch.

Thought it would be drop in....sorry!!The bolt sweeps on the TL3 and RimX are different. You will have to open up the bolt notch on the stock to allow the RimX to close properly. Then you should be good to go.

I have mine in a Manners for a Defiance and did have to open up the bolt notch.

I

Thought it would be drop in....sorry!!

I have mine in a Manners for a Defiance and did have to open up the bolt notch.View attachment 7574649View attachment 7574650

What did you use to open it up? Dremel tool?

Used a die grinder but a Dremel will do it. I finished up with a round carbide sharpening stone. I then used a metallic Sharpies that matched the copper color paint to cover it upWhat did you use to open it up? Dremel tool?

Anyone having eject issues with their RimX? Several of my buddies run a RimX and I just got one last week. We are all using different barrels and are not novice shooters. We are noticing an occasional interesting issue; A round will be fed into the chamber, not ignite, and when we go to extract, the round does not eject, it's "stuck" in the chamber and have to use a pick or something to pull it out. Now this happens not very often; Happened to me 4 times shooting 150 rounds. I'm thinking the chamber just needs to be opened up a hair. But was wondering if anyone had experienced this issue and if they resolved it without "reaming" the chamber...

Anyone having eject issues with their RimX? Several of my buddies run a RimX and I just got one last week. We are all using different barrels and are not novice shooters. We are noticing an occasional interesting issue; A round will be fed into the chamber, not ignite, and when we go to extract, the round does not eject, it's "stuck" in the chamber and have to use a pick or something to pull it out. Now this happens not very often; Happened to me 4 times shooting 150 rounds. I'm thinking the chamber just needs to be opened up a hair. But was wondering if anyone had experienced this issue and if they resolved it without "reaming" the chamber...

I shot a 22x match at gunsite and a guy had that exact issue on the first stage. It was 20ish degrees maybe that had something to do with it? Didn't have any issues the rest of the match.

Mine did this only ones, when a new unexperienced shooter was not running the bolt right. He run it to slow and stopped between.

If this happens I suggest to use a correct coated one piece cleaning rod to get the round out.

If this happens I suggest to use a correct coated one piece cleaning rod to get the round out.

Your mag height is incorrect.Anyone having eject issues with their RimX? Several of my buddies run a RimX and I just got one last week. We are all using different barrels and are not novice shooters. We are noticing an occasional interesting issue; A round will be fed into the chamber, not ignite, and when we go to extract, the round does not eject, it's "stuck" in the chamber and have to use a pick or something to pull it out. Now this happens not very often; Happened to me 4 times shooting 150 rounds. I'm thinking the chamber just needs to be opened up a hair. But was wondering if anyone had experienced this issue and if they resolved it without "reaming" the chamber...

I don't think so. If that was the case it would happen every time and it doesn't... And if some of my friends are having the same issue, I doubt we all have incorrect mag height. We also played with that too...Your mag height is incorrect.

Have you tried cleaning your mags? If the spring gets caught a little it won't force the shell up under the extractor like it is supposed to.I don't think so. If that was the case it would happen every time and it doesn't... And if some of my friends are having the same issue, I doubt we all have incorrect mag height. We also played with that too...

sounds like its jumping in front of the extractor? but the bolt closes?I don't think so. If that was the case it would happen every time and it doesn't... And if some of my friends are having the same issue, I doubt we all have incorrect mag height. We also played with that too...

Bolt does not close. I tried examining it today to see how mag position affected it. Very little slop or movement. Not enough to not capture the round as I watchedsounds like its jumping in front of the extractor? but the bolt closes?

Well I was at Rockland PA today and took the rim x out to 500 with pretty ease. I ran out of travel in the scope. That was the only issue. These things shoot.

Similar threads

- Replies

- 8K

- Views

- 653K

- Replies

- 4

- Views

- 3K

- Replies

- 227

- Views

- 54K

- Replies

- 79

- Views

- 30K

- Replies

- 46

- Views

- 16K